Catalog excerpts

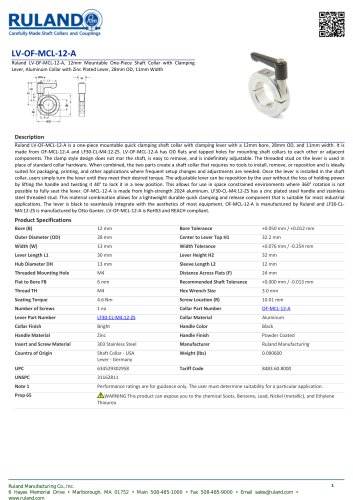

MSCC-20-20-SS Ruland MSCC-20-20-SS, 20mm x 20mm Rigid Coupling, 303 Stainless Steel, Set Screw Style with Keyway, 42mm OD, 65mm Length Description Ruland MSCC-20-20-SS is a set screw rigid coupling with 20mm x 20mm bores, 42mm OD, 65mm length, and 6mm x 6mm keyways. It has precision honed bores to ensure they are collinear and do not introduce misalignment or vibration into the system making it suitable for high precision servo appliactions as well as shaft to shaft connections. Forged screws test beyond DIN 912 12.9 standards to ensure maximum holding power. Tightly controlled bore tolerance of +.050mm/+.012mm is maintained. MSCC-20-20-SS is made from 303 stainless steel with hardware of like material for consistent corrosion resistance. It is machined from solid bar stock that is sourced exclusively from North American mills and is RoHS3 and REACH compliant. MSCC-20-20-SS is manufactured in our Marlborough, MA factory under strict controls using proprietary processes. Product Specifications Bore (B1) Bore Tolerance Recommended Shaft Tolerance Screw Material 18-8 300 Series Stainless Steel Screw Finish Seating Torque Rated Torque Rating Coming Soon Maximum Speed Full Bearing Support Required? Precision Honed Bores? Material Specification Type 303 Austenitic, Non-Magnetic Bar Finish Specification Ruland Manufacturing Tariff Code Performance ratings are for guidance only. The user must determine suitability for a particular application. WARNING This product can expose you to the chemical Nickel (metallic), known to the State of California to cause cancer. For more information go to www.P65Warnings.ca.gov. Installation Instructions 1. Align the MSCC-20-20-SS set screw rigid coupling on the two shafts to be connected. There should be no misalignment. 2. Tighten the set screws in two stages, starting with the inside set screws. Using a 3.0 mm torque wrench, tighten the inside set screws to 2.88 Nm which is half the recommended seating torque. Repeat for the outside set screws, again tightening to half of the recommended seating torque. 3. Tighten the screws to the full recommended seating torque of 5.76 Nm following the same pattern, starting with the inside set screws first. Ruland Manufacturing Co., Inc. 6 Hayes Memorial Drive • Marlborough, MA 01752 • Main 508-485-1000 • Fax 508-485-9000 • Email sales@ruland.com • www.ruland.com Powered by TCPDF (www.tc

Open the catalog to page 1All Ruland Manufacturing Co. catalogs and technical brochures

-

LVO-OF-MCL-IOE-AN

1 Pages

-

LV-0F-MCL-16E-SS

1 Pages

-

LV-0F-MCL-16-A

1 Pages

-

LV-0F-MCL-12-F

1 Pages

-

LV-0F-MCL-12-A

1 Pages

-

M-IPL-8-M16X1.5-F

1 Pages

-

M-IPL-4-M8X1-F

1 Pages

-

M-IPL-4.73-3/8X24-F

1 Pages

-

M-IPL-7.9-5/8X18-F

1 Pages

-

MCL-75-F

1 Pages

-

MCL-54-SS

1 Pages

-

MCL-54-F

1 Pages

-

MCL-50-F

1 Pages

-

MCL-24-F

1 Pages

-

MCL-23-SS

1 Pages

-

MCL-23-F

1 Pages

-

ATCL-12-6-F

1 Pages

-

MSCC-16-16-F

1 Pages

-

MCLC-15-15-F

1 Pages

-

Servo Coupling

4 Pages

Archived catalogs

-

Ruland Shaft Collars & Couplings

16 Pages

-

Ruland Beam Couplings

12 Pages

-

Ruland Oldham Couplings

6 Pages

-

Ruland Jaw Couplings

6 Pages

-

Ruland Bellows Couplings

6 Pages