Catalog excerpts

with innovations for the future Photo Documentation

Open the catalog to page 1

Specialist for Pumping Technology For more than 50 years RUHRPUMPEN GMBH have been developing and manufacturing centrifugal pumps for all RUHRPUMPEN GMBH's manufacturing ranges include technically high-grade pumps for refineries, petrochemical in- stallations, oilfield and pipeline industries and onshore and offshore technology as well as pumps for conventional power stations, environmental technology, gen- eral water engineering, wastewater tech- nology and pumps for dock construction. The centrifugal pumps manufactured tor the process-technology sector can where ever desired also be...

Open the catalog to page 2

with innovations for the future — BARE SHAFT PUMP 28-29

Open the catalog to page 3

Specialist for Pumping Technology

Open the catalog to page 4

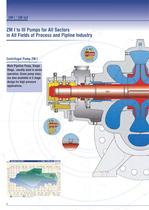

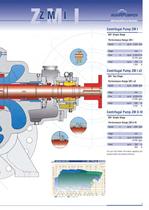

in All Fields of Process and Pipline Industry Main Pipeline Pump, Single Stage, usually used in series operation. Some pump sizes are also available in 2 stage design for high pressure

Open the catalog to page 6

Centrifugal Pump ZM ll-IV Performance Range ZM ll-IV You can find further information regarding this product within our product brochure m UK -an «o: so: ■o:u\r.u -i:o lam iiiio wiu vu:u cin>*:

Open the catalog to page 7

in All Fields of Process and Pipline Industry Special Main Pipeline Pump, tions with change of the flow during the lifetime of a pipeline. Cost saving pump adaption by changing the pump impeller and/or This enables the pump to run changing pipeline flow.

Open the catalog to page 10

in All Fields of Process and Pipline Industry Multi-Stage Main Pipe- line Pump usually used in parallel operation. Larger sizes are available with 1st stage double suction bearing design with forced teed lubrica- high axial loads.

Open the catalog to page 12

Special Impeller Design: In case low NPSHR value is required, a double suction impeller for the first stage is available for most ot the pump sizes.

Open the catalog to page 13

Specialist for Pumping Technology

Open the catalog to page 14

Specialist for Pumping Technology

Open the catalog to page 16

Impeller/Diff user ZM, ZLM and ZMS type have double suction closed impellers at the 1st Stage. All impellers are precision cast- ings and will be dynamically balanced in At the type ZLM different sets of impel- lers/diffusers can be installed in the same casing. Due to this feature the operating range can be increased widely, as well as ensuring high efficiencies. Additionally the radial forces are reduced to a minimum. Impeller and diffuser of a pipeline pump

Open the catalog to page 19

Specialist for Pumping Technology

Open the catalog to page 22

Specialist for Pumping Technology

Open the catalog to page 24

Pump Assembly The lop casing will be lowered to the bottom casing. Both casing parts are sealed by wire mesh

Open the catalog to page 25

Specialist for Pumping Technology

Open the catalog to page 28

Fine Tuning Pipeline pumps are often running un- der severe operation conditions. To assure an excellent, lite-long quality. pumps for pipeline applications are tuned during virtually every step of the manufac- turing process.

Open the catalog to page 31

Specialist for Pumping Technology

Open the catalog to page 32

For 50 Hz the maximum available electrical power is For 60 Hz the max. available electrical power is up to 180 kW. Max. Flow: 9,600 ms/h witti the standard arrangement (pipe diameter from 50 mm up to 600 mm), 20.000 m'Vh with a loop pipe system diameter of 1,200/1,400 mm. Maximum crane lifting capacity: 32 tons Computer-supported evaluation and display of measurements Hydrostatic Test Stand Maximum test -pressure with water at ambient -temperature Quality Resources Design, manufacturing and service codes resp. standards of which Ruhrpumpen have expert knowledge: ASME - Code and others ■ PT...

Open the catalog to page 33

Pumping Units Qp's pipeline pumps are runnin lil lor more than 50 years in many pipelines world-wide to the greatest Our pumps are installed in the main crude oil and product pipelines in Europe. Near/ Middle East and China. RP covers the complete range of Booster-, Tank Storage-, Loading- and Main Pipeline Pumps. Photos beside are showing installations of RP pumps for cavern leaching, as booster pumps in a tank farm and as main pumps

Open the catalog to page 35

Specialist for Pumping Technology

Open the catalog to page 42

1950 The company RUHRPUMPEN GMBH was founded under the name of RUHRPUMPEN GMBH Wende & Hentschel. 1955 Aquisition by the company RUHRSTAHLWERKE AG. trad- ing under the name of RUHRPUMPEN GMBH. 1956 Alliance between RUHRSTAHL and RHEINISCHE STAHL- WERKE, trading under the name of RUHRPUMPEN GMBH. 1957 RUHRPUMPEN GMBH started the production of process pumps under the license of PACIFIC; San Francisco. This was an essential step to a permanent development of the company. 1963 The RUHRPUMPEN GMBH belongs to the company RHEINSTAHL HUTTENWERKE AG within the corporate group RHEINISCHE STAHLWERKE....

Open the catalog to page 43

Specialist for Pumping Technology

Open the catalog to page 46

For over 50 years the name Ruhrpumpen has been a world-wide synonym for innovation and reliability in pumping technology. Pipeline pumps from RP are installed in many european pipelines. Customers can expect the best support from selection through manufacturing. testing and installation to aftermarket sales. Hand in hand with the customer highly experienced engineers are develop- ing optimal solutions for many different Tanker terminal

Open the catalog to page 47

For over 50 years the name RUHRPUMPEN has been synonymous world-wide with innovation and reliability for pumping technology. with innovations for the future RUHRPUMPEN GmbH E-Mail: inIo@ruhrpumpen.de E-Mail: into@ruhrpumpen.com Niquel No. 9204 Ciudad Industrial Mitras. E-Mail: wdm@corporacioneg.com Calle 15 No. 41-17 Zona Industrial Puente Aranda Santa Fe de Bogota, Colombia E-Mail: ventas@barnes.com.co RUHRPUMPEN GmbH PoccmicKafl Oe^epauHfl e-mail: into@ruhrpumpen.de

Open the catalog to page 48All RUHRPUMPEN catalogs and technical brochures

-

HYDRAULIC DECOKING SYSTEMS

8 Pages

-

RP METALS

8 Pages

-

Fire Pump Capabilities

36 Pages

-

FIRE SYSTEMS

10 Pages

-

HS / ZW

8 Pages

-

A LINE

12 Pages

-

SWP

8 Pages

-

CPP Pump Brochure

8 Pages

-

CPO Pump Brochure - EN

10 Pages

-

Brochure GSD pump

4 Pages

-

SM/SMI

8 Pages

-

ST/STV

4 Pages

-

IIL Industrial In-Line Pumps

8 Pages

-

Selection guide

39 Pages

-

Product Overview

3 Pages

-

Split Case.

12 Pages

-

Magnetic Driven Pump

12 Pages

-

Vertical Turbine Pump.

8 Pages

Archived catalogs

-

Water & Wastewater Market

20 Pages