Catalog excerpts

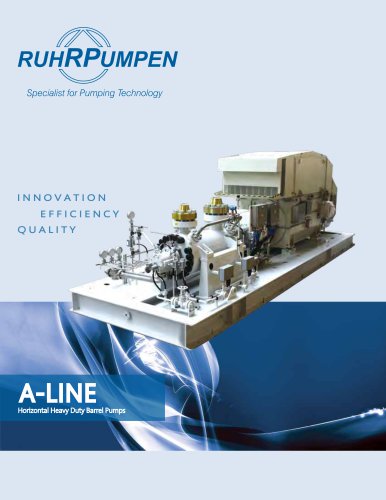

Specialist for Pumping Technology EFFICIENCY QUALITY Horizontal Heavy Duty Barrel Pumps

Open the catalog to page 1

For more than 60 years the name RuhrpumpenTM has been synonymous worldwide with innovation and reliability for pumping technology Ruhrpumpen is an innovative and efficient centrifugal pump technology company that offers a wide range of quality products to our clients. Ruhrpumpen is committed to global excellence with a complete range of Pumps, Fire Pump Packages and related products, such as Decoking Systems and Tools to support the core markets, namely Oil & Gas, Petrochemical, Power, Heavy Industry Applications, Mining and Water Services. The broad product line complies with the most...

Open the catalog to page 2

Horizontal Heavy Duty Barrel Pumps SELECTION CHART A-LINE Materials of Construction Material combinations per API 610 as standard. Other materials on special request.

Open the catalog to page 3

^ Close clearance throttling sleeve and bush. ^ Stage casing - interstage plate with guide vanes and diffuser. - ^ Impeller and casing wear ring secured by tack welding (set screws optional). J Investment cast, closed impellers with transition fit and keyway, secured with split ring. ^ Clamped bearing cover without screws in direction of mechanical seal__ ^ Lubrication sleeve can be used for bearing pull-off. Rigid 360° bearing bracket support. No bearing housing end cover. 19 Double angular contact ball bearings 73 series BECB in O-arrangement 16 Removable interstage sleeve acting as...

Open the catalog to page 4

^ Impellers axially secured in either direction by split rings. 10 Seal chambers sized according to API 610 and API 682. Designed for full MAWP. li| Bearing bracket bolted directly to Pull-Out-Cartridge. 12 Access to diffuser, guide vanes and channels from both sides. 13 Cartridge secured by tie-rods for easy assembly. 14 Balancing line, ASME B16.5 600lbs, MAWP design on special request BACK TO BACK Horizontal Heavy Duty Barrel Pumps PRODUCT DESCRIPTION Horizontal Heavy Duty Barrel Pumps. - API 610 iith edition BB5. - Horizontal multi-stage arrangement. - Opposed Impeller Design -...

Open the catalog to page 5

Replaceable casing wear rings shrink fitted and secured by tack welding. Rigid, 360° bearing bracket support for heavy-duty service and low vibration levels. One-piece inter stage plate with guide vanes and integrated diffuser. Bearing housing equipped with INPRO bearing isolators. Investment cast, closed impeller with transition fit and keyway, secured with split ring. Rigid rotor design. Shaft end tapered with key as standard. Hydraulic fit optional. Replaceable impeller wear rings. Wear ring coating on special request. Shrink fit and secured by tack welding for optimal run-out. 8...

Open the catalog to page 6

Horizontal Heavy Duty Barrel Pumps 12 Optimized outlet for low noise level. 11 Radially split casing, full design pressure, centerline mounted. Forged and welded as well as cast version available. 10 Shaft driven lube oil pump available if required, for hydrodynamic bearings PRODUCT DESCRIPTION Horizontal Heavy Duty Barrel Pumps. - API 610 11th edition BB5. - Horizontal multi-stage with in-line impeller arrangement. - Single suction impeller. Double suction on special request. - Double-casing. - Radially split. - Barrel type. - Between bearings. - Centerline mounted. - Centrifugal pump with...

Open the catalog to page 7

A-Line General Features and Options 1 A Line, In Line Model 8 Images for ilustration purposes not actual construction.

Open the catalog to page 8

A LINE Horizontal Heavy Duty Barrel Pumps Features A Line model 1 HEAVY DUTY PUMP CASING • All flanges designed and rated for full maximum allowable working pressure and 2 x API 610 nozzle loads • Center-line mounted HIGH ROTOR STABILITY • Optimized • Dynamically-stiff design • High reliability for higher speed , low static deflection EASE OF MAINTENANCE • Cartridge can be removed from barrel casing as a complete unit PUMP MONITORING • Temperature and vibration monitoring of critical components as standard • Wired to skid edge junction box or control panel PRECISION CAST IMPELLERS...

Open the catalog to page 9

Main Feautures and Options ADC Model - Design for Decoking Systems A Model - Inline Design • Special design for the highly demanding operating conditions of Decoking System Jet Pumps. • Forged or cast barrel available • Balancing drum takes axial thrust load • Forged and cast barrel available • Inline and Back-to-Back arrangement available • Short builds and small number of stages possible • Hydrodynamic bearings with force fed lubrication available A Line General Features and Options • Antifriction bearings with ring oil lubrication available • Double suction first stage available...

Open the catalog to page 10

Horizontal Heavy Duty Barrel Pumps Horizontal Process Pump Single Stage with Permanent Magnetic Drive Heavy duty centrifugal process pump with permanent magnetic drive, API 685 pump standards, horizontal overhung, single stage,radially split, end suction. Petroleum Refining, Production and Distribution, Petrochemical, Refineries, Heavy-duty Chemical, Gas Industry Services, Power Plants and Utilities. Multi Stage Axially Split Casing Pump Near-centerline mounted, Double volute casing, single or double suction, radial, closed impeller. Heavy duty process design according to API 610 latest...

Open the catalog to page 11

RUHRPUMPEN PLANTS USA, Tulsa & Orland |*| MEXICO, Monterrey ESQ BRAZIL, Rio De Janeiro ARGENTINA, Buenos Aires M GERMANY, Witten “ EGYPT, Suez INDIA, Chennai CHINA, Changzhou

Open the catalog to page 12All RUHRPUMPEN catalogs and technical brochures

-

HYDRAULIC DECOKING SYSTEMS

8 Pages

-

RP METALS

8 Pages

-

Fire Pump Capabilities

36 Pages

-

FIRE SYSTEMS

10 Pages

-

HS / ZW

8 Pages

-

SWP

8 Pages

-

CPP Pump Brochure

8 Pages

-

CPO Pump Brochure - EN

10 Pages

-

Brochure GSD pump

4 Pages

-

SM/SMI

8 Pages

-

ST/STV

4 Pages

-

IIL Industrial In-Line Pumps

8 Pages

-

Selection guide

39 Pages

-

Product Overview

3 Pages

-

Split Case.

12 Pages

-

Magnetic Driven Pump

12 Pages

-

Vertical Turbine Pump.

8 Pages

Archived catalogs

-

Water & Wastewater Market

20 Pages