Website:

RUF. BRIQUETTING SYSTEMS

Website:

RUF. BRIQUETTING SYSTEMS

Catalog excerpts

ADDING VALUE Hausener Straße 101 86874 Zaisertshofen Germany

Open the catalog to page 1

MACHINES AND MORE SUSTAINABILITY WITH TRADITION HISTORY FACTS FIGURES 1969 Hans Ruf founds a company providing services to the forestry industry 1982 The rst press for producing briquettes from organic waste was granted a patent 1988 The rst press for metals was sold 1990 The original company was converted into Ruf Maschinenbau GmbH & Co. KG 1994 A production hall of 1700 m2 was built to manufacture briquetting machinery to process wood, metals & other waste materials 1997 Series production of briquetting machinery for small-scale processing was started 1998 This year marked the delivery of...

Open the catalog to page 2

CYCLE OF VALUES RUF BRIQUETTING SYSTEMS - ALWAYS A GOOD INVESTMENT Sustainable Value Creation – a veritable gain When waste materials from the production process are reclaimed and reused, not only our environment prots. RUF briquetting machinery enables you to add virtually any material to a resource cycle of value: the ideal alternative to the costly disposal of residues. Firstly, briquetting is volume reduction. RUF briquetting systems are designed to compact numerous organic and inorganic chippings as well as other residue, and to turn them into a form which can then be stacked. Are you...

Open the catalog to page 3

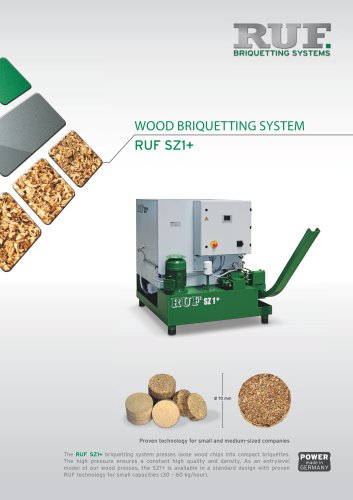

COMPRESS RECYCLE IMPROVE Wood is a natural product. Briquetting changes only the form, not the content. Wood is and remains wood. Even better – as a valuable source of energy, RUF briquettes have an even higher commercial value and an optimal CO2 balance. Examples: Sawdust Wood chips Bark Wood shavings Wood dust RUF machines are hydraulically powered, which ensures that the wood waste is compressed under high pressure into briquettes of uniform size and hardness – without the need for binders. So even after briquetting, wood remains exactly what it is – a pure natural product. Compressed...

Open the catalog to page 4

ADDING VALUE A RICH PALETTE OF VALUE WITH PREMIUM RECYCLING TECHNOLOGY BRIQUETTING VERSATILITY – FROM COTTON TO STYROFOAM Briquettes make an economically and ecologically valuable contribution to your corporate environmental management system. Multifunctional RUF briquetting equipment is distinguished by its innovative processing technique – the crucial requirement necessary for converting metallic residues into valuable secondary raw materials. The energy required for briquetting is just a small fraction of the amount that can be saved in follow-up costs. Examples: Aluminium Steel Castings...

Open the catalog to page 5

COMPETENT & COMPREHENSIVE RUF SERVICE We are a full service provider, delivering comprehensive, expert advice and support for all aspects of sustainable cost optimisation – from consulting and the planning of your specic briquette solution, through to construction, installation, commissioning, maintenance and inspection of your new equipment. VERTICAL MANUFACTURING INTEGRATION Production steps Laser cutting Sheetmetal work Specialist welding operation Control systems Development Construction Milling shop Paint shop Stock of spare parts Assembly Quality assurance Technical department Test...

Open the catalog to page 6

SYSTEMATICALLY APPLIED As the leading provider of systematic briquetting solutions, sustainability is the focus of our production processes. A long service life and the low degree of wear and tear both conserve resources and vouch for our high quality standards. Evident in everything from the precise assembly of individual components to the robust design and construction: RUF machines are built for heavy-duty tasks, operating around the clock. Depending upon the associated equipment and the material to be processed, we manufacture machines tted with hydraulic motors of between 3 kW and 90...

Open the catalog to page 7

VISIONS TURN INTO REALITY ADDING VALUE THROUGHOUT THE WORLD The range of materials we process into briquettes is as varied as life itself. This intriguing insight is our motivation for driving technological innovation forward and allows us to constantly add new materials to the list of those which can be meaningfully recycled. More than 30 years of experience in the briquetting industry is a solid base from which to satisfy every customer‘s requirements. As far as we are concerned, the cycle of value is only complete when we have developed a solution with which you, the customer, are...

Open the catalog to page 8All RUF. BRIQUETTING SYSTEMS catalogs and technical brochures

-

FORMIKA

4 Pages

-

image-brochure

16 Pages

-

Image brochure RUF EN

16 Pages

-

Brochure en

2 Pages

-

RUF_Briquetting of Biomass

2 Pages

-

RUF Foundry Projects

7 Pages

-

RUF Recycling Projects

8 Pages