Website:

RUF. BRIQUETTING SYSTEMS

Website:

RUF. BRIQUETTING SYSTEMS

Catalog excerpts

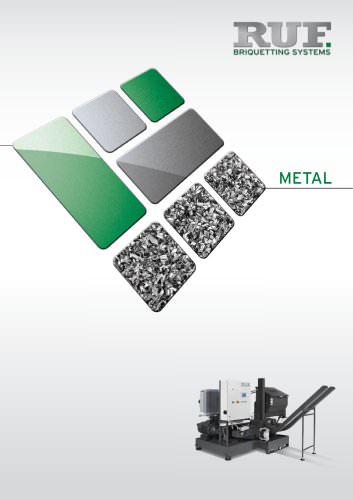

RUF BRIQUETTING SOLUTIONS FOR OPTIMAL METAL RECYCLING Machines Materials Formats Metal chips that are produced in the metal-working industry can be profitably pressed with RUF briquetting systems. Through the process of briquetting, the value of residual metals can be increased considerably. A further advantage is the recovery of expensive cutting fluids that can be pressed out of wet chips and then reused. When melting briquettes, combustion is significantly lower and results in a higher melting yield than with loose chips. Metals can be processed into briquettes measuring between 60x40 mm...

Open the catalog to page 2

BRIQUETTING SYSTEMS PROCESS AND FEATURES Electrical cabinet with touch panel Main drive engine with hydraulic pump Press part Charging screw Discharge chutes Sump pump Sump tray for pressed cutting fluid Legend: • = Standard o = Option

Open the catalog to page 3

Subject to technical modifications. The throughput capacity depends upon the machine design as well as the type and form of the material used. Ruf Maschinenbau GmbH & Co. KG Hausener Str. 101 D-86874 Zaisertshofen Germany Phone: +49 (0) 8268 9090-20 Fax: +49 (0) 8268 9090-90 info@briquetting.com www.briquetting.com

Open the catalog to page 4All RUF. BRIQUETTING SYSTEMS catalogs and technical brochures

-

FORMIKA

4 Pages

-

image-brochure

16 Pages

-

Image brochure RUF EN

16 Pages

-

Brochure en

2 Pages

-

RUF_Briquetting of Biomass

2 Pages

-

RUF Foundry Projects

7 Pages

-

RUF Recycling Projects

8 Pages

-

RUF Briquetting Systems

8 Pages