Website:

RUF. BRIQUETTING SYSTEMS

Website:

RUF. BRIQUETTING SYSTEMS

Catalog excerpts

ADDING VALUE POWER made in

Open the catalog to page 1

SUSTAINABILITY WITH TRADITION HISTORY FACTS FIGURES 1969 Hans Ruf founds a company providing services to the forestry industry 1982 The first press for producing briquettes from organic waste was granted a patent 1988 The first press for metals was sold 1990 The original company was converted into Ruf Maschinenbau GmbH & Co. KG 1994 A production hall of 1700 m2 was built to manufacture briquetting machinery to process wood, metals & other waste materials 1997 Series production of briquetting machinery for small-scale processing was started 1998 This year marked the delivery of...

Open the catalog to page 2

MACHINES AND MORE Welcome to RUF, your partner for sustainable cost optimisation! “Behind every machine is a human being. Behind RUF briquetting equipment are people who create added value.“ Hans Ruf, company founder Dear Customer, as a family business firmly rooted in mechanical engineering and in wood processing, we specialised in the economical use of raw materials from the very beginning. Craftsmen and entrepreneurs today are confronted with the same issues, no matter what business they are in, be it carpentry or agriculture, the steel industry, or textile production: How can we make the...

Open the catalog to page 3

Sustainable value creation – a veritable gain When waste materials from the production process are reclaimed and reused, not only our environment profits. RUF briquetting machinery enables you to add virtually any material to a resource cycle of value: the ideal alternative to the costly disposal of residues. Firstly, briquetting is volume reduction. RUF briquetting systems are designed to compact numerous organic and inorganic chippings as well as other residue, and to turn them into a form which can then be stacked. This results in a number of benefits for you: the more compact the waste...

Open the catalog to page 4

- ALWAYS A GOOD INVESTMENT. Are you briquetting yet, or are you still throwing profits away? Make the most of your residues. With a customised briquetting solution, the cost is minimal. We will put together a briquetting system that is precisely tailored to your needs, appropriate to the materials, the quantities and the production environment. Contact us and ask for a sample briquette! Minimum effort - maximum benefit: ► hydraulic compacting process ► easy installation, modular system ► requires very little space ► energy-efficient operation ► low degree of wear and tear ► extremely...

Open the catalog to page 5

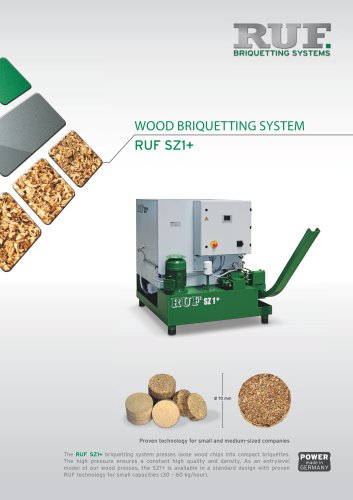

COMPRESS . RECYCLE . IMPROVE Examples: Sawdust Wood chips Bark Wood shavings Wood dust RUF machines are hydraulically powered, which ensures that the wood waste is compressed under high pressure into briquettes of uniform size and hardness - without the need for binders. So even after briquetting, wood remains exactly what it is - a pure natural product. Compressed wood burns at high temperatures, ensuring that a more even combustion process takes place. This results in a number of benefits: briquettes burn longer, more efficiently and produce less ash. The energy content and combustion...

Open the catalog to page 6

Examples: Peat Hay Hemp MDF Horse manure Rape straw Palm straw Miscanthus Coffee grounds Tobacco dust Nut shells Rice husks Almond shells Sunflower seeds For many years, the majority of organic matter created by humans, animals and plants was viewed as a waste disposal problem. In light of increasingly scarce resources, a gradual rethink of the situation came about. Biomass is now playing an increasingly important role in the field of renewable energies. Most organic materials can be transformed into compact, naturally pure briquettes possessing excellent calorific value by means of the...

Open the catalog to page 7

Aluminium Steel Castings Grinding sludge Brass Copper Bronze Titanium Zinc Magnesium ADDING VALUE WITH PREMIUM RECYCLING TECHNOLOGY Briquettes make an economically and ecologically valuable contribution to your corporate environmental management system. Multifunctional RUF briquetting equipment is distinguished by its innovative processing technique - the crucial requirement necessary for converting metallic residues into valuable secondary raw materials. The energy required for briquetting is just a small fraction of the amount that can be saved in follow-up costs. Metal shavings, swarf...

Open the catalog to page 8

A RICH PALETTE OF VALUE .BRIQUETTING VERSATILITY - FROM COTTON TO STYROFOAM It's a numbers game! Those who work economically with the resources at their disposal know that even the smallest particle is part of a large profit. This is not necessarily about financial gain alone. Examples: Paper Cardboard Fabric remnants Cotton Banknotes Styrofoam Paint dust Paper dust Dust from electronic waste PU from recycled refrigerators Sewage sludge Grinding dust Security is a further important factor in many recycling management processes. When disposing of banknotes, banks use briquetting systems to...

Open the catalog to page 9

VERTICAL MANUFACTURING INTEGRATION Production steps Laser cutting Sheetmetal work Specialist welding operation Control systems Development Construction Milling shop Paint shop Stock of spare parts Assembly Quality assurance Technical department Test press

Open the catalog to page 10

COMPETENT & COMPREHENSIVE RUF SERVICE We are a full service provider, delivering comprehensive, expert advice and support for all aspects of sustainable cost optimisation – from consulting and the planning of your specific briquette solution, through to construction, installation, commissioning, maintenance and inspection of your new equipment. A Reliable Partner – Before and After Purchase Save Time with Flexibility We base our tailor-made briquetting solutions on an assessment of each customer‘s individual needs. We manufacture machines that are specifically designed to meet your...

Open the catalog to page 11

SYSTEMATICALLY APPLIED As the leading provider of systematic briquetting solutions, sustainability is the focus of our production processes. A long service life and the low degree of wear and tear both conserve resources and vouch for our high quality standards. Evident in everything from the precise assembly of individual components to the robust design and construction: RUF machines are built for heavy-duty tasks, operating around the clock. Depending upon the associated equipment and the material to be processed, we manufacture machines fitted with hydraulic motors of between 3 kW and 90...

Open the catalog to page 12All RUF. BRIQUETTING SYSTEMS catalogs and technical brochures

-

FORMIKA

4 Pages

-

image-brochure

16 Pages

-

Brochure en

2 Pages

-

RUF_Briquetting of Biomass

2 Pages

-

RUF Foundry Projects

7 Pages

-

RUF Recycling Projects

8 Pages

-

RUF Briquetting Systems

8 Pages