Catalog excerpts

We prevent explosions in industrial plants We protect the health and lives of your employees Reduce the risk of irrecoverable damages and losses in production

Open the catalog to page 1

ZAŘÍZENÍ NA POTLAČENÍ VÝBUCHU – HRD SYSTÉM CUSTOMER SERVICES SYSTEM FOR EXPLOSION SUPPRESSION HRD SYSTEM EXPLOSION VENTING EXPLOSION VENTING DEVICES FLEX FLAMELESS VENTING EXPLOSION ISOLATION SYSTEM BACK PRESSURE FLAP B-FLAP HRD BARRIER QUICK-ACTING SLIDE VALVE ANTI-EXPLOSION DIVERTER If there are the following things available at a given location and time: then explosion risk becomes a real threat. OXYGEN EXPLOSION PROTECTION OF BUCKET ELEVATORS ELEVEX • Substances that create explosive atmosphere • Sufficient amount of oxygen or another oxidizing agent • Effective ignition source Proudly...

Open the catalog to page 2

CUSTOMER SERVICES OUR CUSTOMER CARE REPRESENTS: AVAILABILITY We are available on the phone, computer or directly in the field – in order for our reaction to be as fast as possible and you had the least amount of worries with our supplies. Everything related with your requirements is solved as quickly as possible. We all take care of your supplies that is why it is easy for us to understand you. Thanks to our knowledge and experience we can advise you and help you with correct decisions. WHAT WE OFFER: PROCESSING OF INPUT REQUIREMENTS – solution of “ATEX” questions • Creation of fire –...

Open the catalog to page 3

HRD SYSTEM – SYSTEM FOR EXPLOSION SUPPRESSION HRD (high rate discharge) system is a well-tried system for explosion suppression. It detects the initial phase of explosion and then suppresses explosions of flammable dusts in industrial technologies. The equipment reaction time counts in milliseconds. Thanks to its perfect THE HRD SYSTEM WILL PROTECT filters and filtration units, industrial vacuums, silos, mills, dryers, cyclones, conveyors, dust reservoirs, elevators, mixers, crushers and other industrial equipment against explosion effects. DIAGRAM OF HRD SYSTEM INSTALLATION ON A SEPARATOR...

Open the catalog to page 4

SYSTEM FOR EXPLOSION SUPPRESSION – HRD SYSTEM BASIC PARTS OF THE HRD SYSTEM CONTROL UNIT EXPLOSION DETECTOR Simple or multiple zone control unit evaluates and archives detector information, activates extinguishing bottles, monitors circuits for connection of other devices, provide data to superior systems and serves as a user interface to the operators. Pressure detectors recognize incipient explosion in time. They will pass this information to the control unit extremely quickly. Their advantage is a short reaction time (in milliseconds) and variability of use. Special HRD vessels equipped...

Open the catalog to page 5

EXPLOSION VENTING DEVICES – EXPLOSION VENTING Explosion venting devices are protection devices intended for protection of industrial equipment with explosion danger. RSBP equipment for explosion venting is a perfect solution to lower this risk and eliminate losses that follow such explosions. RSBP explosion venting devices offer very effective and economical solution of protection against damages resulting from a powder explosion. ADVANTAGES: These devices are primarily suitable for protection of filters, reservoirs, mills, crushers, cyclones and other equipment with dust explosion...

Open the catalog to page 6

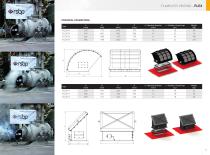

EXPLOSION VENTING - EXPLOSION VENTING DEVICES VMP - DOMED ROUND EXPLOSION VENTING DEVICES • Domed triple layer venting devices with PTFE isolation • For equipment with operational temperature of up to 240 °C • High underpressure resistance • Stainless steel or carbon steel with anti-corrosion finish • Suitable also for equipment with pressure pulses • SU - Domed triple layer venting devices with PTFE isolation • Certification according to EN 14 797 Type SU* *SU - Domed triple layer venting devices with PTFE isolation

Open the catalog to page 7

EXPLOSION VENTING DEVICES - EXPLOSION VENTING VMP - FLAT RECTANGULAR EXPLOSION VENTING DEVICES • Suitable for applications with low operational pressure (up to 50 % of safety opening pressure) • For equipment with operational temperature of up to 100 °C • Possibility of frameless installation • Stainless steel • Economical solution • F - Flat venting devices • Certification according to EN 14 797 VMP - DOMED RECTANGULAR EXPLOSION VENTING DEVICES • Single layer construction for equipment with operational temperature of up to 100 °C • Triple layer construction with high underpressure...

Open the catalog to page 8

• Suitable for applications with low operational pressure and without pressure pulses • Material: Carbon steel, galvanized • Capability to be used repeatedly • For technologies with very low pressure resistance TECHNICAL PARAMETERS: • Venting devices opening indicator • Optional temperature isolation • Optional frames for VMP - D/SU

Open the catalog to page 9

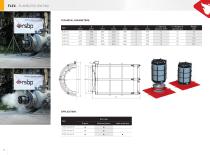

FLEX – FLAMELESS VENTING FLEX meets the most stringent legislative requirements for flameless explosion venting devices. The FLEX flameless device to relieve explosion is a suitable solution for installation on technological equipment inside buildings or production halls. FLEX guarantees explosion venting in enclosed or internal spaces without propagation of flame, dangerous pressure and heat to near surroundings, therefore the equipment and technologies that are located in hard to access spaces can be protected by the flameless explosion venting without increased costs for building...

Open the catalog to page 10

Poiirni a vybucbova ochnria " : •' -■ '.''ivWpdKiw I FLAMELESS VENTING - FLEX TECHNICAL PARAMETERS: Type PofcArni a vybuchovi ochrjna * F ro an] Poiarni a vybuchova ochfifla Fr* an] e<WmM»a

Open the catalog to page 11

TECHNICAL PARAMETERS: T A B C D E APPLICATION: Type Dust type Light metal dust FLEX series R • • FLEX series F • • FLEX series C • • •

Open the catalog to page 12

EXPLOSION ISOLATION SYSTEM – BACK PRESSURE FLAP B-FLAP B-FLAP is a mechanical device designed to prevent propagation of flame and pressure between pieces of technology equipment during explosion. B-FLAP is, together with other safety measures, a part of a system that protects technologies intended for operation in an explosion danger environment. Economical solution of protection against propagation of explosion to pipes is the B-FLAP back flap. B-FLAP is suitable for prevention of explosion propagation from input pipes of filters, reservoirs, cyclones and other devices with danger of dust...

Open the catalog to page 13