Website:

Rotork

Website:

Rotork

Group: Rotork

Catalog excerpts

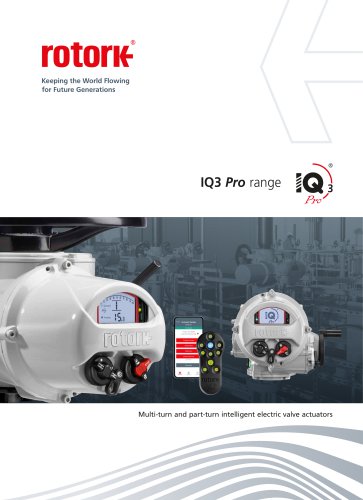

Multi-turn and part-turn intelligent electric valve actuators

Open the catalog to page 1

Reliability in critical flow control applications Reliable operation when it matters Assured reliability for critical applications and environments. Whether used infrequently or continuously, Rotork products will operate reliably and efficiently. Customer focused service and worldwide support Rotork solve customer challenges and develop new solutions that are tailored to the needs of our clients. We offer dedicated, expert service and support from initial inquiry, to product installation, to long-term after sales care. Quality-driven global manufacturing We offer products that have been...

Open the catalog to page 2

Fieldbus compatibility Product range features Actuator specification Performance summaries Actuator selection for linear valve types Actuator drive couplings Actuator selection for part-turn valve types Design features Rotork Master Station - network capabilities Comprehensive product range serving multiple industries Rotork products offer improved efficiency, assured safety and environmental protection across sectors such as the Power, Oil & Gas, Water & Wastewater, HVAC, Marine, Mining, Pulp & Paper, Food & Beverage, Pharmaceutical and Chemical sectors. Global presence, local service We...

Open the catalog to page 3

Product range features The most robust actuator design in the industry providing exceptional reliability Continuous position tracking at all times, even without power Easy installation and maintenance using detachable thrust bases On power loss, graphical interface, remote indication and data logger are maintained and accessible Remote operation, configuration and commissioning up to 100 m from actuator, with Remote Hand Station Oil bath lubrication provides extended life and the ability to mount in any orientation Safe, motor-independent, handwheel operation available at all times Water...

Open the catalog to page 4

Direct-drive and geared handwheels are sized for effective manual operation of the valve. Handwheel drive is independent of the motor drive and is selected with a lockable lever for safe operation even when the motor is running. See Section 9.1. Patented absolute position encoder is provided to enable robust, high accuracy measurement of up to 8,000 actuator output rotations under all conditions, including loss of mains power. See Section 9.7. 2. Environmental sealing IP66/68; 7 m for 72 hours State-of-the-art piezo torque sensor for IQ provides reliable torque measurement over a wide...

Open the catalog to page 7

Actuator selection for linear valve types Actuator selection for linear valve types: Wedge, conduit / slab, parallel slide, globe, choke, knife, sluice / weir, diaphragm. Torque/thrust range - actuator availability Direct Class / starts-hour Torque lbf.ft Thrust Class / starts-hour Thrust Class / starts-hour Direct - control valve IQTF (A coupling*) IQTF (L coupling*) Min Class / starts-hour

Open the catalog to page 8

Actuator selection for part-turn valve types Actuator selection for part-turn valve types: Butterfly, ball, plug, damper. Torque range - actuator availability Direct Torque Class / starts-hour With IW/MOW gearbox Torque Class / starts-hour Direct - control valve Torque Class / starts-hour IQT Fail-to-position options IQT, IQTM and IQTF actuators are compatible with two fail-to-position solutions. The Shutdown Battery option is suitable for use in hazardous and safe areas. The Battery Backup option is suitable for use in safe areas only. Both fail-to-position solutions will perform a...

Open the catalog to page 9

Design features Simple, secure commissioning and configuration Technological advances Ensuring correct configuration and keeping it secure is the bedrock of reliable operation. All IQ3 Pro actuators can be set up non-intrusively using the Rotork app on a smartphone, Rotork Bluetooth® Setting Tool Pro (BTST) handset or via manual setup using the actuator control knobs. Torque levels, position limits, control and indication functions can all be accessed using any of these setting options. Bluetooth wireless connectivity with a smartphone or BTST allows easy use without direct line-of-sight,...

Open the catalog to page 10

Unrivalled industry-leading reliability Asset management Valve operation must be reliable. Rotork IQ3 Pro range actuators are engineered for a lifetime of uninterrupted service in the toughest applications. Built on the Rotork drive train, proven since 1957, IQ3 Pro range actuators retain industry leading reliability: With an advanced display, position, torque, status and configuration data is clear and immediately accessible. In addition, the valve, actuator and process data is available in real-time on screen or in the control room. Valve stroke torque/thrust graphs, duty trend logs,...

Open the catalog to page 11

Design features Indication power With the absolute encoder, a battery is not required for position sensing and tracking. As all configuration and data logger data is stored in non-volatile EEPROM memory, all settings are safe when no power is available. However, to maintain the display and ensure remote indication is kept updated, allow datalogging and power off commissioning, an indication battery is included as standard. Reduced power consumption means the battery has an exceptionally long life and low-cost replacements are available from suppliers globally. In addition, the auxiliary...

Open the catalog to page 12

Remote field operation The Remote Hand Station Pro (RHS Pro) uses the same display and controls interface as the IQ3 Pro actuator, allowing users to remotely operate, interrogate and configure the actuator from up to 100 m distance. Due to the familiar, featurerich interface, set up could not be simpler using the Rotork Bluetooth® Setting Tool Pro supplied with the IQ actuator, Rotork app or manual setup using the local control knobs. In the event of overheating, two thermostats embedded in the motor windings directly sense the temperature and trip the actuator control circuit. Duplicating...

Open the catalog to page 13

Design features Vibration measurement Lifetime support Vibration can severely affect the performance and lifetime of plant equipment and its effects are cumulative. Levels of vibration can vary significantly, depending on process conditions such as start up and shutdown, valve cavitation and at different flow rates, making it difficult to capture with mobile measuring devices. With communication featuring Bluetooth wireless technology, the onboard data logger and the new dual-stacked display, the IQ range offers unrivalled support to provide complete product backup with local analysis and...

Open the catalog to page 14All Rotork catalogs and technical brochures

-

RH Range

8 Pages

-

Padlock Device

1 Pages

-

Local Hand Station

2 Pages