Website:

Rotor Clip Company

Website:

Rotor Clip Company

Catalog excerpts

I’s Quality Source for ensating Hose Clamps ROTOR CLAMP

Open the catalog to page 1

NOW YOU HAVE A CHOICE: Competition makes for a healthy marketplace and Rotor Clamp provides a double dose of it with its full line of 100% AMERICAN MADE, selfcompensating hose clamps. Purchase clamps at a low price from a manufacturer known for its quality and reliability. Use our products with confidence since they are produced by Rotor Clip Company, Inc., a world class manufacturer of retaining rings and hose clamps. Rotor Clamp is currently certified to ISO/TS16949:2002. With continuous improvement as our theme, we move into the future ready to meet our customer's demand for quality...

Open the catalog to page 2

ROTOR CLAMP Self-Compensating Hose Clamps *Expands/Contracts with hose in response to temperature changes. *Cannot be over/under tightened. *Can be installed automatically eliminating Carpal Tunnel Syndrome (CTS), a nerve disorder of the hand and wrist *Less time for assembly - resulting in lowered production costs. Competition Screw / Worm Type Hose Clamps *Must be manually adjusted as temperature changes. *Screw mechanism maybe over/under tightened causing damage/leakage to the hose. *Must be manually installed. *More time needed for assembly/disassembly due to screw adjustment....

Open the catalog to page 3

HC Hose Clamps - Single Wire EFFECTIVE CLAMPING RANGE: After expanding to no greater than “A” diameter of the gage, the clamp in relaxed condition shall not pass over “D” diameter. When clamp is assembled on “A”, “B” or “C” diameter of gage, a wire of “X” diameter shall not pass between gage and clamp when inserted in a direction parallel to the axis of the gage. FINISH: Peen-Plate Zinc (non-electrolytic process) .0002 minimum thickness plus dichromate treatment. MATERIAL: Specially processed premium grade spring wire, hardened and austempered to meet the performance requirements specified....

Open the catalog to page 4

HW Hose Clamps - Slim Clamps Rotor Clamp HC No. PreOpened, PrePositioned Clamps This unique, patented version of a preopened clamp is held in the open position by compressing the tangs and allowing the stop to hook on to a complementary notch on the side of one of the tangs.The hook catches this “dimple” when the clamp is opened for a more secure hold. The clamp can then be glued in position on a hose.The mechanism to hold the clamp open is accomplished with only minor changes to the original design of the clamp. The clamp cannot be preopened any further than the stop, ensuring the clamp...

Open the catalog to page 5

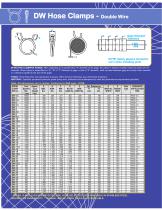

DW Hose Clamps - Double Wire ROTOR CLAMP DW No.

Open the catalog to page 6

Rotor Clamp CTB No. (mm) * Magni 511 offers five times the corrossion protection over traditional zin Blue, Green and Red (Mechanical Zinc is also available along with other .in Magni 511 meets the following automotive specifications: General Motors: G ESA-M21P5A; Ford World Wide: WSD-21P11-B1, WSD-21P11-B2; Chrysler C , It is available in Black, Silver, Brown, Inquire for more information). H-M; GM-7112-M; Ford Motor Compai oration: PS-7626.

Open the catalog to page 7

CTL Hose ClampsBand Light FINISH: Phosphate; Mechanical Zinc Plate MATERIAL: SAE 1060-1090 Spring Steel, Austempered CTN - CONSTANT TENSION BAND NARROW CTN’s are available in a width of 12mm, and are typically used in places where a standard width CTB band clamp (15mm) is too wide for the application. CTN clamps are suited for applications that would normally require a CTB clamp. Nominal diameters range from 13mm to 90mm. Contact Rotor Clamp for more specifications.

Open the catalog to page 8

INSTALL/REMOVE ROTOR CLAMP HOSE CLAMPS WITH THESE DURABLE, QUALITY ENGINEERED TOOLS. Single Wire (HC/HW) Hose Clamp Double Wire (DW) Hose Clamp Constant Tension Band (CTB) Pneumatic Tool (PWS) Pneumatic Tool (PWD) Pneumatic Tool (PBC-1)* *Specify PBC-1 for any Rotor Clamp CTB Hose PNEUMATIC TOOL FEATURES: Clamp you are installing. One size fits all. •Tangs of the clamp fit in the jaws of the tool and are compressed for installation or removal on the hose. •Uses a compressed air line of 90 psi. •Activated by a simple lever reducing stress on the hand from repeated...

Open the catalog to page 9

Three elements are required in a typical joint design: the hose, the fitting and the clamp. These elements must meet certain performance and materi al specifications if they are to function successfully in a given application. Here are some points to keep in mind when addressing joint design: I. HOSE: There are many types of hose constructions and materials. A common automotive type is EPDM rubber compound with a Shore A hardness of 60 durometer. Other materials of construction are silicone or a combination of EPDM and silicone. Many are reinforced with an inner layer of woven fabric. A.The...

Open the catalog to page 10

ROTOR CLAMP ENGINEERS HELP YOU DESIGN THE RIGHT ELEMENTS FOR SUCCESSFUL HOSE/JOINT CONNECTION. B.You can use a smaller clamp on an application to increase force. This can be done by placing the clamp on the fitting, installing the hose and sliding the clamp "backwards" up to the bead. C.Ideally, a clamp should be sized to fit onto the joint when opened to 90% of full (as a safety factor) and close to no less than the nominal (size) diameter when in the final position . III.FITTING The fitting is the portion of the joint over which the hose is installed. To reap the full benefits of a...

Open the catalog to page 11

Carbon Steel CTB Clamps Reduce Costs Constant Tension Band hose clamps have been traditionally made from 6150 chrome-vanadium steel. However, research by Rotor Clamp indicates you can achieve the same results with 1074 cabon steel at far less the cost. SAE 1074 yields higher average hardness without the risk of untempered martensite in its struture. This translates into more robust performance with a less costly raw material. Rotor Clamp tested 1074 and 6150 CTB clamps for performance equivalency using Pressure/Temperature Leak Testing, Fatigue Testing and Radial Force Testing. Visit...

Open the catalog to page 12All Rotor Clip Company catalogs and technical brochures

-

Company Overview

44 Pages

-

Wave Spring Catalog

44 Pages

-

Distribution Brochure

16 Pages

-

Oil & Gas Industry Brochure

8 Pages

-

Medical Industry Brochure

8 Pages

-

Aerospace Industry Brochure

12 Pages

-

Automotive Industry Brochure

12 Pages

-

Product Catalog

276 Pages

-

THE ULTIMATE RETAINING

72 Pages

-

Rotor Clip Oil & Gas

8 Pages

-

Rotor Clip Wind Power

4 Pages

-

Rotor Clip Company Overview

44 Pages

-

Wave Springs

8 Pages

Archived catalogs

-

CTB

1 Pages

-

HO

6 Pages

-

CFS

3 Pages

-

DE

1 Pages

-

DSH

2 Pages

-

DHI

2 Pages

-

BSH

2 Pages

-

E

2 Pages

-

SH

6 Pages

-

MCG

2 Pages

-

DCR

2 Pages

-

MKA

2 Pages

-

MKG

2 Pages

-

MKR series

2 Pages

-

Retaining Ring Plier Kits

1 Pages

-

Retaining Ring Kits

1 Pages

-

DSI

2 Pages

-

DSH

8 Pages

-

DHR

1 Pages

-

DHT

2 Pages

-

Applicators and dispensers

3 Pages

-

Hose clamp tools pneumatic

1 Pages

-

HC Hose Clamps

1 Pages

-

KMS Shims

1 Pages

-

Wave springs

12 Pages

-

PO Shaft Rings

2 Pages

-

LC Shaft Rings

2 Pages

-

VHS Shaft Rings

4 Pages

-

BSH Shaft Rings

2 Pages

-

SHM Shaft Rings

2 Pages

-

SHI Shaft Rings

2 Pages

-

SHR Shaft Rings

2 Pages

-

SH Shaft Rings

6 Pages

-

VHO Shaft Rings

6 Pages

-

BHO Shaft Rings

2 Pages

-

HOI Shaft Rings

2 Pages

-

HO Shaft Rings

6 Pages

-

Bearing Chart

3 Pages