Website:

Rotor Clip Company

Website:

Rotor Clip Company

Catalog excerpts

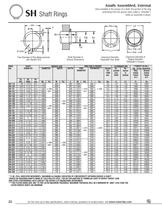

Axially Assembled, External Once installed in the groove of a shaft, the portion of the ring protruding from the groove (also called a "shoulder") holds an assembly in place. Free Diameter & Ring Measurements Shaft Diameter & Groove Dimensions Clearance Diameter Expanded Over Shaft Clearance Diameter & Gaging Diameter **SIZES -12 THRU -23 STANDARD MATERIAL- CARBON STEEL; OPTIONAL MATERIAL- BERYLLIUM COPPER. * F.I.M. {FULL INDICATOR MOVEMENT}- MAXIMUM ALLOWABLE DEVIATION OF CONCENTRICITY BETWEEN GROOVE & SHAFT. i BASED ON HOUSINGS/SHAFTS MADE OF COLD ROLLED STEEL. FOR AN EXPLANATION OF FORMULAS USED TO DERIVE THRUST LOAD AND OTHER PERFORMANCE DATA CONTACT THE ROTOR CLIP ENGINEERING DEPARTMENT. ***F0R PLATED RINGS ADD .002" TO THE LISTED MAXIMUM THICKNESS. MAXIMUM THICKNESS WILL BE A MINIMUM OF .0002" LESS THAN THE LISTED GROOVE WIDTH (W) MINIMUM. For the most up-to-date specifications, online ordering, quotations & sample orders, visit www.rotorclip.com

Open the catalog to page 1

Maximum Corner Radius & Chamfer Exploded Groove Profile & Edge Margin (Y) Maximum bottom radii (R), sharp corners for ring sizes -12 thru -23; .003 for ring sizes -25 thru -35; .005 for sizes -37 thru -100; .010 for Alternate Design Manufacturer's Option FOR HARDNESS SPECIFICATIONS, SEE END OF THIS SECTION. For the most up-to-date specifications, online ordering, quotations & sample orders, visit www.rotorclip.com

Open the catalog to page 2

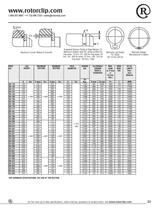

Axially Assembled, External Once installed in the groove of a shaft, the portion of the ring protruding from the groove (also called a "shoulder") holds an assembly in place. Free Diameter & Ring Measurements Shaft Diameter & Groove Dimensions Clearance Diameter Expanded Over Shaft Clearance Diameter & Gaging Diameter * F.I.M. (FULL INDICATOR MOVEMENT)- MAXIMUM ALLOWABLE DEVIATION OF CONCENTRICITY BETWEEN GROOVE & SHAFT. i BASED ON HOUSINGS/SHAFTS MADE OF COLD ROLLED STEEL. FOR AN EXPLANATION OF FORMULAS USED TO DERIVE THRUST LOAD AND OTHER PERFORMANCE DATA CONTACT THE ROTOR CLIP...

Open the catalog to page 3

Maximum Corner Radius & Chamfer Exploded Groove Profile & Edge Margin (Y) Maximum bottom radii (R), sharp corners for ring sizes -12 thru -23; .003 for ring sizes -25 thru -35; .005 for sizes -37 thru -100; .010 for Alternate Design Manufacturer's Option FOR HARDNESS SPECIFICATIONS, SEE END OF THIS SECTION. For the most up-to-date specifications, online ordering, quotations & sample orders, visit www.rotorclip.com

Open the catalog to page 4

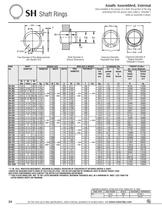

Axially Assembled, External Once installed in the groove of a shaft, the portion of the ring protruding from the groove (also called a "shoulder") holds an assembly in place. Free Diameter & Ring Measurements Shaft Diameter & Groove Dimensions Clearance Diameter Expanded Over Shaft Clearance Diameter & Gaging Diameter * F.I.M. (FULL INDICATOR MOVEMENT)- MAXIMUM ALLOWABLE DEVIATION OF CONCENTRICITY BETWEEN GROOVE & SHAFT. i BASED ON HOUSINGS/SHAFTS MADE OF COLD ROLLED STEEL FOR AN EXPLANATION OF FORMULAS USED TO DERIVE THRUST LOAD AND OTHER PERFORMANCE DATA CONTACT THE ROTOR CLIP ENGINEERING...

Open the catalog to page 5

Maximum Corner Radius & Chamfer Exploded Groove Profile & Edge Margin (Y) Maximum bottom radii (R), sharp corners for ring sizes -12 thru -23; .003 for ring sizes -25 thru -35; .005 for sizes -37 thru -100; .010 for Alternate Design Manufacturer's Option LARGER SIZES MAY BE AVAILABLE UPON REQUEST. HARDNESS RANGES: CARBON STEEL RINGS (SAE 1050-1090) HARDNESS RANGES: BERYLLIUM COPPER RINGS 1 HARDNESS CAM NOT BE CHECKED WITH ANY DEGREE OF ACCURACY DIRECTLY ON THESE RINGS. For the most up-to-date specifications, online ordering, quotations & sample orders, visit www.rotorclip.com

Open the catalog to page 6All Rotor Clip Company catalogs and technical brochures

-

Company Overview

44 Pages

-

Wave Spring Catalog

44 Pages

-

Distribution Brochure

16 Pages

-

Oil & Gas Industry Brochure

8 Pages

-

Medical Industry Brochure

8 Pages

-

Aerospace Industry Brochure

12 Pages

-

Automotive Industry Brochure

12 Pages

-

Product Catalog

276 Pages

-

THE ULTIMATE RETAINING

72 Pages

-

THE WORLD' QUALITY SOURCE

12 Pages

-

Rotor Clip Oil & Gas

8 Pages

-

Rotor Clip Wind Power

4 Pages

-

Rotor Clip Company Overview

44 Pages

-

Wave Springs

8 Pages

Archived catalogs

-

CTB

1 Pages

-

HO

6 Pages

-

CFS

3 Pages

-

DE

1 Pages

-

DSH

2 Pages

-

DHI

2 Pages

-

BSH

2 Pages

-

E

2 Pages

-

SH

6 Pages

-

MCG

2 Pages

-

DCR

2 Pages

-

MKA

2 Pages

-

MKG

2 Pages

-

MKR series

2 Pages

-

Retaining Ring Plier Kits

1 Pages

-

Retaining Ring Kits

1 Pages

-

DSI

2 Pages

-

DSH

8 Pages

-

DHR

1 Pages

-

DHT

2 Pages

-

Applicators and dispensers

3 Pages

-

Hose clamp tools pneumatic

1 Pages

-

HC Hose Clamps

1 Pages

-

KMS Shims

1 Pages

-

Wave springs

12 Pages

-

PO Shaft Rings

2 Pages

-

LC Shaft Rings

2 Pages

-

VHS Shaft Rings

4 Pages

-

BSH Shaft Rings

2 Pages

-

SHM Shaft Rings

2 Pages

-

SHI Shaft Rings

2 Pages

-

SHR Shaft Rings

2 Pages

-

VHO Shaft Rings

6 Pages

-

BHO Shaft Rings

2 Pages

-

HOI Shaft Rings

2 Pages

-

HO Shaft Rings

6 Pages

-

Bearing Chart

3 Pages