Website:

Rotor Clip Company

Website:

Rotor Clip Company

Catalog excerpts

Company Overview

Open the catalog to page 1

ROTOR CLIP QUALITY Rotor Clip is certified and registered to ISO/TS 16949:2009 & ISO 9001:2008. Under these guidelines, departments conduct value stream meetings to evaluate goals and measure efficiency and effectiveness. This goal driven philosophy results in cost reduction opportunities that are passed along to our customers. "We meet the customer's standards for quality, not just quality standards." - Craig Slass, Co-President/Owner, Rotor Clip. Rotor Clip takes quality to a new level by helping customers achieve more than acceptable quality standards. We recently developed equipment to...

Open the catalog to page 3

It all begins with engineering, the skilled translation of your needs into accurate, concise engineering language. Our engineers do more than execute drawings: They analyze engineering problems to find solutions and produce designs that stress efficiency and maximum Our engineers design the tooling for every part Rotor Clip produces. Their techniques ensure a steady flow of types and sizes of product to meet the demands of customers. Nowhere in the industry is there a more sophisticated tool room for building high speed, progressive dies than at Rotor Clip Company. All personnel follow...

Open the catalog to page 4

Manufacturing We Form & Cut It... Rotor Clip produces larger retaining rings from wire to increase efficiency and reduce costs by eliminating waste. We are the leaders in this technology with modern wire-forming machinery engineered to meet our exacting standards of production. For prototype samples or small quantities of retaining rings where no tool exists, Rotor Clip can laser cut your requirements quickly and effectively. We Heat Treat It... All Rotor Clip carbon steel retaining rings and hose clamps are heat treated using the austempering method. Parts are heated in one of six...

Open the catalog to page 5

Support We Support The Product... Rotor Clip supports its products with a full line of Retaining ring kits, pliers, applicators, dispensers... Everything you need to install/remove retaining rings or hose clamps is available to you from one source. We Support The Customer... We support our customers from the moment they contact us. Whether it’s placing an order, requesting design assistance for an assembly, addressing quality issues, or finding just the right part, Rotor Clip is there to help. The Customer Service, Technical Sales, Engineering and Quality Assurance Departments are staffed...

Open the catalog to page 6

ENVIRONMENTAL COMMITMENT In the past the management of Rotor Clip has demonstrated a commitment to environmentally responsible business practices by dedicating significant resources to correcting and/or eliminating sources of pollution. This has been and will continue to be the manner in which Rotor Clip conducts business. -Excerpt from ISO/TS16949 Document EX/WP294 OTHER ENVIRONMENTAL COMMITMENTS... In House Water Treatment facility — Years ago, we designed and built our own in house treatment facility to effectively remove metals present in the water as a by product of our processes....

Open the catalog to page 7

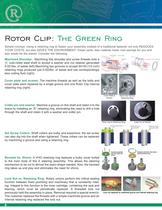

ROTOR CLIP: THE GREEN RING Simple concept. Using a retaining ring to fasten your assembly instead of a traditional fastener not only REDUCES YOUR COSTS, but also SAVES THE ENVIRONMENT. Fewer parts, less material mean cost savings for you and less waste for the planet. Consider the following: Machined Shoulder: Machining this shoulder and screw threads onto a 1/4" cold-rolled steel shaft to accept a washer and nut retainer generated 0.021 lbs. of waste (left).Machining two grooves to accept SH-50 (1/2 inch) retaining rings produced just 0.003lbs. of waste and use correspondingly less cutting...

Open the catalog to page 8

ALL RINGS HAVE A FUNCTION... No one retaining ring style is "better" than another. Rather, the parameters of an application actually determine which retaining ring is best to use, and this can vary from assembly to assembly. Selecting the correct type of retaining ring based on variables such as installation/removal requirements, anticipated thrust load, and end play take-up can ensure the retaining ring you choose will perform reliably, while significantly reducing fastener costs. There are three main types of retaining rings available to the designer: tapered, constant section and spiral....

Open the catalog to page 9

Ring Attributes The Right Ring For Your Application TAPERED SECTION RETAINING RINGS - Axially Assembled: • Axially installed into machined grooves in housings/bores (internal) or on shafts (external) • Have lug holes for ease of installation/removal • Make uniform contact when released in a groove • Can accommodate higher thrust loadings TAPERED SECTION RETAINING RINGS - Radially Assembled: • Radially installed into machined grooves on shafts (external) • Accommodate lower thrust loadings than axial retaining rings • Do not have lug holes: Easy to install using retaining ring applicators •...

Open the catalog to page 10

Using wave springs can reduce traditional coil spring heights as much as 50% saving weight and costs as well as reducing overall assembly sizes. Coil Spring Wave Spring WAVE SPRING TYPES WAVE SPRING TERMS Static: A spring that holds a load at a given height for the life of the assembly; there is no cycling of the part. Dynamic: A spring that is constantly moving up and down until the end of its life. It has two working heights and hence, two loads. Generally, the higher the cycle life the stronger the spring needs to be. Gap Single Turn/Overlap Single Turn Standard Inch (SST) /Narrow Inch...

Open the catalog to page 11

ROTOR CLAMP SELF-COMPENSATING HOSE CLAMPS Rotor Clamp provides a full line of 100% AMERICAN MADE, self-compensating hose clamps. Purchase clamps from a manufacturer known for its quality and reliability. Use our products with confidence since they are produced by Rotor Clip Company, Inc., a world class manufacturer of retaining rings Rotor Clamp is currently certified to ISO/TS16949:2009. With continuous improvement as our theme, we move into the future ready to meet our customer's demand for quality innovation Easier to install and less expensive than the standard screw/worm type clamps,...

Open the catalog to page 12All Rotor Clip Company catalogs and technical brochures

-

Company Overview

44 Pages

-

Wave Spring Catalog

44 Pages

-

Distribution Brochure

16 Pages

-

Oil & Gas Industry Brochure

8 Pages

-

Medical Industry Brochure

8 Pages

-

Aerospace Industry Brochure

12 Pages

-

Automotive Industry Brochure

12 Pages

-

Product Catalog

276 Pages

-

THE ULTIMATE RETAINING

72 Pages

-

THE WORLD' QUALITY SOURCE

12 Pages

-

Rotor Clip Oil & Gas

8 Pages

-

Rotor Clip Wind Power

4 Pages

-

Wave Springs

8 Pages

Archived catalogs

-

CTB

1 Pages

-

HO

6 Pages

-

CFS

3 Pages

-

DE

1 Pages

-

DSH

2 Pages

-

DHI

2 Pages

-

BSH

2 Pages

-

E

2 Pages

-

SH

6 Pages

-

MCG

2 Pages

-

DCR

2 Pages

-

MKA

2 Pages

-

MKG

2 Pages

-

MKR series

2 Pages

-

Retaining Ring Plier Kits

1 Pages

-

Retaining Ring Kits

1 Pages

-

DSI

2 Pages

-

DSH

8 Pages

-

DHR

1 Pages

-

DHT

2 Pages

-

Applicators and dispensers

3 Pages

-

Hose clamp tools pneumatic

1 Pages

-

HC Hose Clamps

1 Pages

-

KMS Shims

1 Pages

-

Wave springs

12 Pages

-

PO Shaft Rings

2 Pages

-

LC Shaft Rings

2 Pages

-

VHS Shaft Rings

4 Pages

-

BSH Shaft Rings

2 Pages

-

SHM Shaft Rings

2 Pages

-

SHI Shaft Rings

2 Pages

-

SHR Shaft Rings

2 Pages

-

SH Shaft Rings

6 Pages

-

VHO Shaft Rings

6 Pages

-

BHO Shaft Rings

2 Pages

-

HOI Shaft Rings

2 Pages

-

HO Shaft Rings

6 Pages

-

Bearing Chart

3 Pages