Website:

Rotor Clip Company

Website:

Rotor Clip Company

Catalog excerpts

ROTOR CLIP COMPANY, INC!Certified to ISO/TS 16949 • ISO 9001 • AS9100 • ISO 14001 Rotor Clip® U.S.A. - World Headquarters 187 Davidson Avenue, Somerset, NJ 08873 USA + 1 732-469-7333 • Fax: +1 732-469-7898 E-mail: sales@rotorclip.com • www.rotorclip.com

Open the catalog to page 2

For the most up-to-date specifications, online ordering, quotations & sample orders, visit www.rotorc

Open the catalog to page 3

Product Index Axially Assembled, Inch Tapered Section Retaining Rings Internal External O Ol o SHM BSH VSH Page 32-33 Page 36-37 Page 44-47 Radially Assembled, Inch Tapered Section Retaining Rings External Axially Installed Self-Locking, Inch Tapered Section Retaining Rings External Internal Axially Assembled, Metric Tapered Section Retaining Rings Internal External Radially Installed DHR DIN 472 Heavy Type Page 80 Radially Assembled, Metric Tapered Section Retaining Rings External DSI DST DSR Page 90-91 DIN 983 DIN 471 Page 92-93Heavy Type Page 81 Self-Locking, Metric Tapered...

Open the catalog to page 4

Product Index Inch Constant Section Retaining Rings OOOOOOOnon HN UHO UHB USC USH Page 119 Page 120-121 Page 122-124 Page 125-127 Page 128 Metric Constant Section Retaining Rings Shims Internal/External HBM,HBH DIN 7993 Page 139-142 Page 132-133 TYPE B Page 146 Inch Spiral Retaining Rings Internal TruWave® Rings Internal External KL KM KR KG KLR CL CM CR CG CLR Page 148-149 Page 152-155 Page 160-161 Page 164-167 Page 172-173 Page 150-151 Page 156-159 Page 162-163 Page 168-171 Page 174-175 Metric Spiral Retaining Rings Internal DKR DKL KLM MKM MKR MKG MKA DCR DCL CLM MCM MCR MCG MCA DIN 472...

Open the catalog to page 5

Rotor Clip Your Single Source All Rings Have A Function... A discussion of retaining rings must inevitably begin with a debunking of myths; namely, that one style retaining ring will function better than all other types in all instances. No one retaining ring style is “better” than another. Rather, the parameters of an application actually determine which retaining ring is best to use, and this can vary from assembly to assembly. Selecting the correct type of retaining ring based on variables such as installation/removal requirements, anticipated thrust load, and end play take-up can ensure...

Open the catalog to page 6

Ring Attributes The Right Ring For Your Application TAPERED SECTION RETAINING RINGS - Axially Assembled: • Axially installed into machined grooves in housings/bores (internal) or on shafts (external) • Have lug holes for ease of installation/removal • Make uniform contact when released in a groove • Can accommodate higher thrust loadings • Provide more of a shoulder with which to retain a component or assembly than constant section or spiral retaining rings TAPERED SECTION RETAINING RINGS - Radially Assembled: • Radially installed into machined grooves on shafts (external) • Accommodate...

Open the catalog to page 7

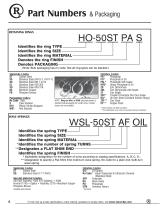

Part Numbers & Packaging RETAINING RINGS HO-50SI PA S Identifies the ring TYPE Identifies the ring SIZE Identifies the ring MATERIAL Denotes the ring FINISH Denotes PACKAGING (Note: Bulk packaging has no code. Not all ring types can be stacked.) Materials Codes: ST Carbon Steel Packaging Codes: No Code Bulk S Tape Stacked RO1 Plastic Shrink Wrapped Finishes Codes: PA* Phosphate PAL* Phosphate with Sealer ZDL Zinc Dichromate with Sealer Z3X* Trivalent Chromate Zinc Plus Sealer OIL* Oil Over Steel (Constant Section Rings) ZFF** Zinc Flash * These finishes are RoHS...

Open the catalog to page 8

rotorclip.com Online Place Your Order Online: www.rotorclip.com You can choose to use the automated check out feature in department stores and grocery markets. Why shouldn’t you be able to automate your industrial purchases? Now you can. As a current/prospective customer, Rotor Clip invites you to take advantage of our online ordering system to help you reduce your transaction costs and to make important information like order status, availability and quote status available to you when you want to see it. No need to make a phone call or wait for a customer service person to lookup your...

Open the catalog to page 9

Standard material for Rotor Clip retaining rings is carbon spring steel (SAE 1060-1090/UNS G10600-G10900). Rings can also be produced in our standard stainless steel (PH 15-7 Mo/UNS S15700) with DIN 1.4122 as an option, and in our standard beryllium copper (Alloy #25/UNS C17200) with phosphor bronze (Alloy#5218/UNS C52180) as an option. Please note that the availability of rings in the stainless steel and copper materials is subject to prior inquiry and acceptance of a formal quotation. Rotor Clip can also produce rings one gauge thicker or thinner than standard sizes. Again, such orders...

Open the catalog to page 10

Tapered/Constant Section Rings Finishes PHOSPHATE COATING (PA) - This standard finish is recommended over unfinished plain steel since it offers an extended shelf-life protection against rusting. RoHS compliant. THERE IS NO ADDITIONAL CHARGE FOR THIS FINISH. PHOSPHATE AND OIL (PD) - This finish provides 8-hour salt spray protection. RoHS compliant. PHOSPHATE WITH SEALER (PAL) - A coating is added to the finish to control loose phosphate crystals on the surface of the part. RoHS compliant. HEAVY PHOSPHATE AND OIL (HPD) - This finish provides 72 salt spray hours and can be used in place of...

Open the catalog to page 11

Materials: CARBON SPRING STEEL (ST) This steel is known for its high strength and reliability in spiral ring applications. Since carbon steel is subject to corrosion, Rotor Clip rings are oil dipped to ensure some corrosion resistance. STAINLESS STEEL - AISI 302 (SJ) This general purpose stainless steel offers corrosion resistance and can be cold worked to high tensile strengths. STAINLESS STEEL - AISI 316 (SU) This type of stainless steel is heat resistant with superior corrosion resistance than other chromium nickel steels. It offers high creep strength at elevated temperatures...

Open the catalog to page 12

Wave Springs For the most up-to-date specifications, online ordering, quotations & sample orders, visit www.rotordip.com Wave Spring Advantage TruWave flat wire wave springs help to save up to 50% of axial space in your application when compared to conventional coil springs. The result is more compact applications in which unnecessary space and therefore excess material of neighboring components can be reduced to a minimum. The flat wire effectively reduces the solid height of the wave spring so that with the same amount of turns one can visibly reduce the work height without compromising...

Open the catalog to page 13All Rotor Clip Company catalogs and technical brochures

-

Company Overview

44 Pages

-

Wave Spring Catalog

44 Pages

-

Distribution Brochure

16 Pages

-

Oil & Gas Industry Brochure

8 Pages

-

Medical Industry Brochure

8 Pages

-

Aerospace Industry Brochure

12 Pages

-

Automotive Industry Brochure

12 Pages

-

THE ULTIMATE RETAINING

72 Pages

-

THE WORLD' QUALITY SOURCE

12 Pages

-

Rotor Clip Oil & Gas

8 Pages

-

Rotor Clip Wind Power

4 Pages

-

Rotor Clip Company Overview

44 Pages

-

Wave Springs

8 Pages

Archived catalogs

-

CTB

1 Pages

-

HO

6 Pages

-

CFS

3 Pages

-

DE

1 Pages

-

DSH

2 Pages

-

DHI

2 Pages

-

BSH

2 Pages

-

E

2 Pages

-

SH

6 Pages

-

MCG

2 Pages

-

DCR

2 Pages

-

MKA

2 Pages

-

MKG

2 Pages

-

MKR series

2 Pages

-

Retaining Ring Plier Kits

1 Pages

-

Retaining Ring Kits

1 Pages

-

DSI

2 Pages

-

DSH

8 Pages

-

DHR

1 Pages

-

DHT

2 Pages

-

Applicators and dispensers

3 Pages

-

Hose clamp tools pneumatic

1 Pages

-

HC Hose Clamps

1 Pages

-

KMS Shims

1 Pages

-

Wave springs

12 Pages

-

PO Shaft Rings

2 Pages

-

LC Shaft Rings

2 Pages

-

VHS Shaft Rings

4 Pages

-

BSH Shaft Rings

2 Pages

-

SHM Shaft Rings

2 Pages

-

SHI Shaft Rings

2 Pages

-

SHR Shaft Rings

2 Pages

-

SH Shaft Rings

6 Pages

-

VHO Shaft Rings

6 Pages

-

BHO Shaft Rings

2 Pages

-

HOI Shaft Rings

2 Pages

-

HO Shaft Rings

6 Pages

-

Bearing Chart

3 Pages