Catalog excerpts

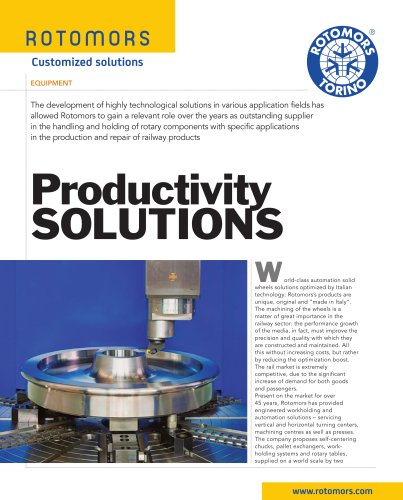

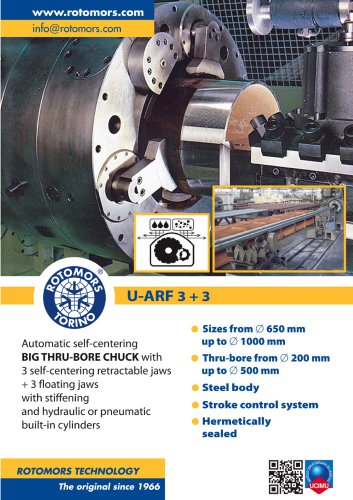

COMPANY Customized solutions EQUIPMENT The development of highly technological solutions in various application fields has allowed Rotomors to gain a relevant role over the years as outstanding supplier in the handling and holding of rotary components with specific applications in the production and repair of railway products by THE EDITORIAL STAFF VTL or machining centre, we nd rst of all the possibility of integration of existing systems. Not infrequently, in fact, in the workshops are already present pallets of other manufacturers: Rotomors is able to t both on the hardware and software side, to perform any activity. The most evident quality of the Pallet-changing system is its capacity of preparing the equipment of machines, with great exibility in the retooling operation. CUTBACK THE IDLE TIME systems. Tested and implemented both on new and on retrotted machines, Rotomors solutions reduce “idle time”, performing pallet-changing systems conceived for real productive applications. Among the most signicant advantages of choosing an automatic exchanger for a Other features are the elimination of the idle time for part loading/unloading, the set-up of the next machining operation while the spindle is turning to improve productivity, the possible application for” lights out” unattended operation on machines, the most efcient handling for part loading/unloading under full safety conditions for the operator, the dimensional controls of the parts outside the machine, the elimination of idle work in process and greatly improved operator safety. Besides, further advantages are provided by choosing Rotomors “turn-key” delivered systems, such as higher stiffness due to the coupling system between pallet and pallet carrier, higher accuracy reached through a unique, adjustable and selfaligning slant rest pad system. Located at the extreme periphery of the pallet receiver, the slant rest pad surfaces offer the same advantages of very large Hirth coupling with added features. The systems can be integrated with DINnorm existing pallets exchangers and are available in several congurations featuring modular design concept. The starting test and the adjustment can be carried out on 3D dimensional control machines by CNC. These products are at disposal in different size ranges from 400 up to 3000 mm, available with automatic or manual workholding including 2-3-4-6-12 jaw chucks. Last but not least, of course, the automation will operate in unmanned modality then it can achieve a quick investment return assured by the intensive use of plants. For further information: Rotomors S.p.A. ROTOMORS S.p.A. Via San Paolo, 62/64 Via San Paolo 62/64 10095 Grugliasco - Torino 10095Grugliasco (TO) Italy (Italy) info@rotomors.com Tel. +39 011 78.57.57 www.rotomors.com - info@rotomors.com www.rotomors.com Productivity SOLUTIONS W orld-class automation solid wheels solutions optimized by Italian technology: Rotomors’s products are unique, original and “made in Italy”. The machining of the wheels is a matter of great importance in the railway sector: the performance growth of the media, in fact, must improve the precision and quality with which they are constructed and maintained. All this without increasing costs, but rather by reducing the optimization boost. The rail market is extremely competitive, due to the signicant increase of demand for both goods and passengers. Present on the market for over 45 years, Rotomors has provided engineered workholding and automation solutions – servicing vertical and horizontal turning centers, machining centres as well as presses. The company proposes self-centering chucks, pallet exchangers, workholding systems and rotary tables, supplied on a world scale by two

Open the catalog to page 1

COMPANY Rotomors considers pre-sales contacts and after-sales service essential and therefore they are supervised carefully by headquarters and local agents. In the range of the company’s products we nd the automatic clamping systems with possible diameter sizes from 200 to 6.000 mm, the hydraulic and pneumatic powered rotating cylinders, automatic indexing chucks for valves, sleeves and pipes for the oil industry drivers for railway axles, clamping equipments for light alloy wheels, with sizes from 13” to 20”, automatic pallet-changing systems and powered shuttles for vertical lathes,...

Open the catalog to page 2

COMPANY Rotomors considers pre-sales contacts and after-sales service essential and therefore they are supervised carefully by headquarters and local agents. In the range of the company’s products we nd the automatic clamping systems with possible diameter sizes from 200 to 6.000 mm, the hydraulic and pneumatic powered rotating cylinders, automatic indexing chucks for valves, sleeves and pipes for the oil industry drivers for railway axles, clamping equipments for light alloy wheels, with sizes from 13” to 20”, automatic pallet-changing systems and powered shuttles for vertical lathes,...

Open the catalog to page 3

COMPANY Customized solutions EQUIPMENT The development of highly technological solutions in various application fields has allowed Rotomors to gain a relevant role over the years as outstanding supplier in the handling and holding of rotary components with specific applications in the production and repair of railway products by THE EDITORIAL STAFF VTL or machining centre, we nd rst of all the possibility of integration of existing systems. Not infrequently, in fact, in the workshops are already present pallets of other manufacturers: Rotomors is able to t both on the hardware and software...

Open the catalog to page 4All ROTOMORS catalogs and technical brochures

-

GD-M-3A

2 Pages

-

GD-RI 2+2

2 Pages

-

GD-RI 3A+3F

2 Pages

-

GD-RF 3+3

2 Pages

-

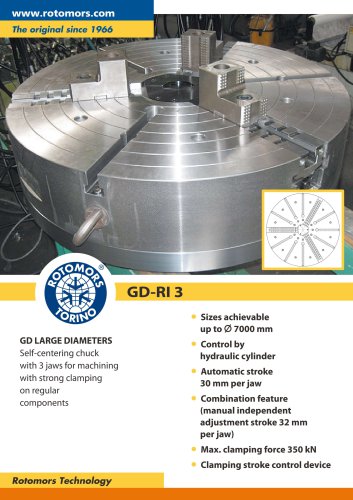

GD-RI 3

2 Pages

-

MINI IDRO-P

2 Pages

-

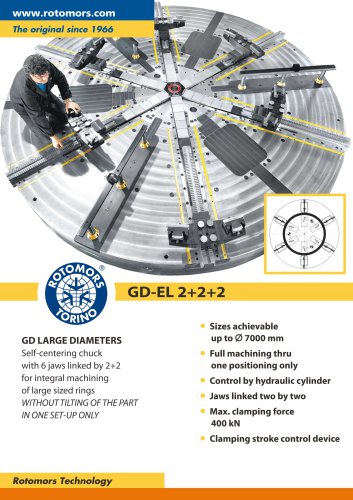

GD-EL 2+2+2

2 Pages

-

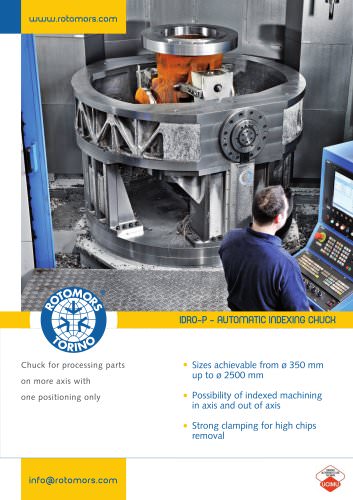

IDRO P-4

2 Pages

-

B-AM AT

2 Pages

-

GD-RI 6 JAWS 3A+3F

2 Pages

-

AM-AT 2-3-4 jaws

2 Pages

-

PRODUCTS RANGE

8 Pages

-

PRODUCTIVITY SOLUTIONS

2 Pages

-

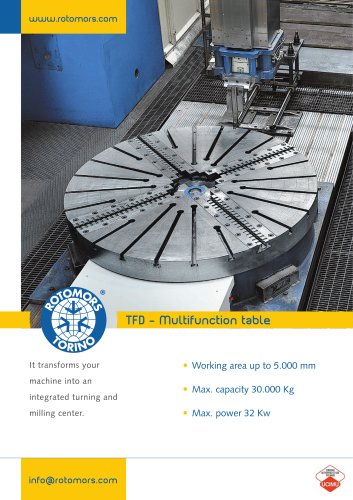

TFD - MULTIFUNCTION TABLE

3 Pages

-

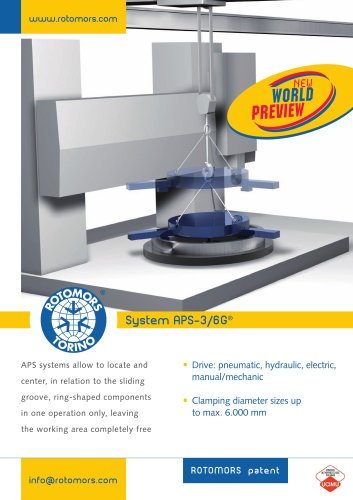

APS-3-6G System

3 Pages

-

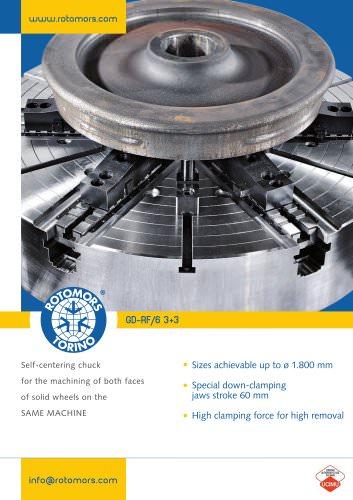

Self Centering Chuck GD-RF/6 3+3

3 Pages

-

self centering chuck

3 Pages