Catalog excerpts

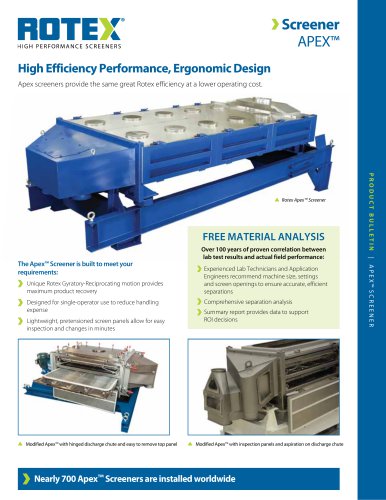

Feeders,Screeners & Conveyors How it Works Feeders,Screeners & Conveyors Direct Drive™ Satisfy Light to Heavy Duty Applications in a Cost-Effective Way How it Works: Direct Drive Feeders & Conveyors Drive mechanism: The utilisation of contra-rotating electromechanical motors imparts both an upward & forward stroke to the main feeder body. The angle of the motors determines the preference towards either lift or conveying. The stroke can be adjusted from zero to around 10mm in most cases. Screens: Screens are usually of a hook strip design with manual tensioning or of a taper slot finger design in the form of removable modular baskets. Typical media designs include - square aperture & slotted aperture mesh. Rod decks, taper finger decks, piano wire, perforated plate. The Direct Drive Product Range is designed for screening, feeding and conveying your product in a cost effective way. Direct Drive Feeder Twin vibrator drive Specification: Direct Drive Screeners, Feeders & Conveyors Enclosures: Covers can be offered with either bolted or quick release mechanisms. Fully enclosed systems use Trelleborg type seals & enclosed shrouds. Sizes: Sizes range from 200mm – 2m wide & from 0.5m to over 6m long. Hopper interface: For hopper bottom installations Rotex can provide either an open type or fully enclosed type interface with or without a rod gate isolation system. Drives: The drives are from an electromechanical range with adjustable weights for accurate tuning. Voltages & IP requirements can be offered to suit most applications. Screens: Typical media designs include - square aperture & slotted aperture mesh. Rod decks, taper finger decks, piano wire, perforated plate. Direct Drive Screener Direct Drive Feeders and Conveyors are designed and built to meet your requirements: utilisation of contra-rotating electromechanical The motors imparts both an upward & forward stroke to the main feeder body. The angle of the motors determines the preference towards either lift or conveying. Various installation options include Rosta, Barrel or Suspension style mounts. Safety straps are fitted where relevant. Rotex can provide either an open type or fully enclosed type interface with or without a rod gate isolation system for hopper bottom installations. Free material analysis Over 100 years of proven correlation between lab test results and actual field performance: Experienced Lab Technicians and Application Engineers recommend machine size, settings and screen openings to ensure accurate, efficient separations Comprehensive separation analysis Summary report provides data to support ROI decisions “Rotex Direct Drive feeders have a reputation for reliability and simplicity. The use of Rosta mounts significantly improves machine stability during start/stop conditions.” Production Manager - Phosphatic Fertilizer Processor To find your local Rotex™ representative visit www.rotex.com Direct Drives are suitable for most processing plants Continuous one piece tray sections PRODUCT BULLETIN Suspended or floor mounted Fully isolated design Construction: All machines are available in either mild or stainless steel construction. Liners are available in most materials such as – Mild steel, Stainless, UHMWP, Abro, Hardox, Alumina, Ceramic. Rotex Europe has designed a full range of Direct Drive® Feeders and Conveyors for meeting all process requirements in the bulk handling industries. PRODUCT BULLETIN Isolation mounts: Rosta mechanical, standard barrel type mounts can be used for all foot mounted requirements. For suspension design isolation rods & rubber mounts are provided along with safety straps. Hopper interface: For hopper bottom installations Rotex can provide either an open type or fully enclosed type interface with or without a rod gate isolati

Open the catalog to page 1

Direct Drive Feeders Specifications Direct Drive Conveyors Specifications B Model Reference Number Principal Dimensions Medium Duty LDDF 400-1000 M LDDF 500-1000 M LDDF 600-1000 M LDDF 400-1500 M LDDF 500-1500 M LDDF 600-1500 M LDDF 800-1500 M LDDF 1000-1500 M LDDF 1200-1500 M LDDF 400-2000 M LDDF 500-2000 M LDDF 600-2000 M LDDF 800-2000 M LDDF 1000-2000 M LDDF 1200-2000 M LDDF 1600-2000 M LDDF 400-2500 M LDDF 500-2500 M LDDF 600-2500 M LDDF 800-2500 M LDDF 1000-2500 M LDDF 1200-2500 M LDDF 1600-2500 M Heavy Duty LDDF 800-1500 H LDDF 1000-1500 H LDDF 1200-1500 H LDDF 800-2000 H LDDF...

Open the catalog to page 2All Rotex catalogs and technical brochures

-

Rotex brochure

4 Pages

-

Apex aspiration

1 Pages

-

Apex tool-less

1 Pages

-

Apex brochure

4 Pages

-

Plastic Pellet Screener

2 Pages

-

Apex

1 Pages

-

Rotex?

1 Pages

-

Hi Cline

2 Pages

-

Megatex XD

2 Pages