Catalog excerpts

RADIAL PISTON MOTORS

Open the catalog to page 1

ABOUT US Rotary Power specialises in the design, development and manufacture of hydraulic motors and pumps. With a history dating back over 50 years, we understand the exacting and demanding requirements of today's hydraulic applications. Operating from 18,000 sq. m. of purpose built manufacturing facilities in the UK and India, we continue to invest in the latest CNC machinery, automation and testing facilities. We have a clear focus on continuous improvement in lean cellular manufacturing. These facilities, alongside our European and US operations, offer sales, service and production...

Open the catalog to page 2

CONFIGURATIONS HEAVY DUTY MOBILE, MARINE AND INDUSTRIAL DRIVES ROTATING SHAFT C1 MOTOR Can operate up to pressures of 490 bar and may experience external loading. ROTATING SHAFT C1 HIGH POWER MOTOR Can operate up to pressures of 490 bar and may experience external loading and higher than standard running speeds. ROTATING SHAFT C2 (DUAL DISPLACEMENT) MOTOR Can operate up to pressures of 490 bar and may experience external loading. Used in applications which require a wide speed range from limited pump flows. The SMA heavy duty motor is of radial piston, eccentric shaft configuration. The...

Open the catalog to page 3

MOTOR ORDER CODE PRODUCT DISPLACEMENT TYPE Sequential reference number determined by Rotary Power according to motor build specification* 'Individual motor specification including shaft type, seals, valves and other options will be established at the time of ordering when the build reference number is issued. A number of special features can be applied to the SMA motor. Please contact us for individual application requirements. OUTPUTSHAFTS • Male keyed and splined shafts to special, metric, imperial and SAE standards • Female plain, keyed and splined shafts to metric, imperial and SAE...

Open the catalog to page 4

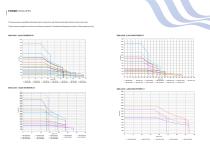

POWER ENVELOPES The below power capabilities should be read in conjunction with the technical data charts for each motor type. These charts are based on maximum continuous values for C1 standard and high power motors. Other types may vary.

Open the catalog to page 5

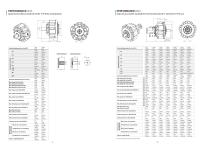

TECHNICAL DATA NOTES The notes below correspond with the numbered data in the following datasheets. 1. Intermittent values up to the maximum shown may occur for up to 10% of every minute as part of a known duty cycle, subject to approval. 2. Whether or not the motor shaft is rotating, positive gauge pressure must be maintained at both main ports at all times whilst the motor is under load. Boost pressure should not be less than 7 bar above case pressure with a fluid viscosity of 30 cSt. When utilising higher viscosities, higher boost pressures will be required. For over-running conditions,...

Open the catalog to page 6

Nominal displacement (cc/rev ) [in3]

Open the catalog to page 7

Nominal displacement (cc/rev) [in3]

Open the catalog to page 8

Nominal displacement (cc/rev) [in3]

Open the catalog to page 9

Nominal displacement (cc/rev) [in3]

Open the catalog to page 10

PERFORMANCE DATA SMA ROTATING CASE MOTOR TYPE B1 STANDARD PERFORMANCE DATA SMA DUAL DISPLACEMENT ROTATING SHAFT MOTOR TYPE C2 Nominal displacement (cc/rev) [in3] Nominal displacement (cc/rev) [in3] Please contact Rotary Power for second speed data.

Open the catalog to page 11

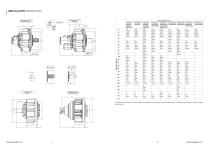

ROTATING SHAFT C1 & C1 HIGH POWER MOTORS TE TATISG CASE Cl METETS The dimensions shown above are approximate and subject to change without notice. Before finalising your installation, please ask for a copy of the latest issue drawing. Rotary Power SMA 122175 21 22 Rotary Power SMA 122175

Open the catalog to page 12

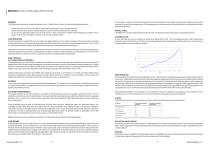

GENERAL The following information is for general guidance only. Contact Rotary Power to discuss individual applications. • Always examine the motor externally to check that damage has not occurred during transit • Ensure the areas around the protective plugs are clean and remove all protective coatings • Do not remove protective plugs from the main ports or drain connections until the system flushing is complete. Once plugs are removed, immediate connection to the circuit should be made CASE MOUNTING Provision is made for locating the motor by means of a spigot diameter on the motor...

Open the catalog to page 13

MOTOR INSTALLATION During system assembly thoroughly descale, clean and flush the pipework, fittings and the reservoir. Fill the systems with new filtered fluid ensuring that it meets the required viscosity specifications at envisaged operating temperature, type and cleanliness for all components. The motor case must be filled through the motor case drain port on a rotating shaft motor, or through one of the case vent ports located in the crankcase on a rotating case motor. Ensure that the case drain line is filled and all connections are tightened. 2. Check the rotation flow information...

Open the catalog to page 14

UK Rotary Power Waldridge Way Simonside East Industrial Park South Shields Tyne and Wear NE34 9PZ T: +44 (0) 191 276 4444 F: +44 (0) 191 276 4462 E: enquiries@rotarypower.com Germany Rotary Power Lukasstrahe 25a 52070 Aachen Germany T: +49 (0) 241 955 190 E: info.ac@rotarypower.com USA Rotary Power Inc. 3952 West Tickman Street Unit 4 Sioux Falls SD 57107 T: +1 (605) 361 5155 F: +1 (605) 362 1949 E: info@rotarypower.com India Rotary Power 6A, Attibele Industrial Area Anekal Taluk Bangalore 562 107 T: +91 (80) 782 0011 F: +91 (80) 782 0013 E: indiaenquiries@rotarypower.com © Rotary Power Ltd...

Open the catalog to page 15All Rotary Power catalogs and technical brochures

-

SMA MOTOR

2 Pages

-

C RANGE PUMP

1 Pages

-

XJ20 Catalogue

32 Pages

-

C | Range

9 Pages

-

Rotary Power Company Overview

20 Pages

-

XJ40 catalogue

28 Pages

-

XJ05 catalogue

32 Pages