Catalog excerpts

Selection table for free oscillating systems (with unbalanced excitation) One mass system circular motion screen Oscillating Mountings One mass system linear motion screen Two mass system with counterframe One mass system linear motion screen hanging Oscillating Mounting – universal mounting. High vibration isolation and low residual force transmission. Natural frequencies approx. 2–3 Hz. 9 sizes from 50 N to 20’000 N per AB. Oscillating Mounting for impact loading and high production peaks. (Heavy Duty) Natural frequencies approx. 2.5–3.5 Hz. 6 sizes from 500 N to 14’000 N per AB-HD. Oscillating Mounting in compact design. Optimal in two mass systems as counterframe mounting. Natural frequencies approx. 3–4.5 Hz. 7 sizes from 500 N to 16’000 N per AB-D. Oscillating Mounting made from stainless steel for the food and pharmaceutical industry. High vibration isolation and low residual force transmission. Natural frequencies approx. 2–3 Hz. 6 sizes from 70 N to 6’800 N per ABI. Oscillating Mounting for hanging systems. Natural frequencies approx. 3–4 Hz. 5 sizes from 500 N to 14’000 N per HS. Selection table for gyratory sifters AK Page 2.36 Universal Joint for the support or suspension of positive drive or freely oscillating gyratory sifting machines. 10 sizes up to 40’000 N per AK. Gyratory sifter upright staying Gyratory sifter hanging Single Joint specially designed with large rubber volume for the suspension of gyratory sifting machines. Models with right-hand and left-hand threads. 5 sizes up to 16’000 N per AV.

Open the catalog to page 1

conveying direction Design layout and evaluation Subject Mass of the empty channel and drive of which approx. 50 % coupling * Total vibrating mass * Mass distribution: feed end Load per corner feed end Load per corner discharge end discharge end Acceleration due to gravity Element choice in example Oscillating stroke in operation Motor revolutions Centrifugal force of both drives Oscillating machine factor Machine acceleration Natural frequency suspensions fe Oscillating machine factor 2π ( 60 · n ) · sw 2 Oscillating stroke empty channel Oscillating stroke (Amplitude peak to peak) Working...

Open the catalog to page 2

Technology Determination of the average material conveying speed vm Main inuencing factors: – Conveying ability of the material – Height of the bulk goods – Screen box inclination – Position of unbalanced motors – Position of the center of gravity 53 32 Diagram for angle of inclination β = 45° to the horizontal The material speed on circular motion screens does vary, due to differing screen-box inclination angles. Resonance amplification and continuous running Laboratory measurements of a typical development of the residual forces on a ROSTA screen suspension: vertical force continuous...

Open the catalog to page 3

Compression load AB-HD The deection values are based on our catalogue specications and should be understood as approximate values. Please consult also our tolerance specications in chapter “Technology” in the general catalogue. Final element deection = s x 1,09 Diagrams showing the vertical deection s (in mm) by compression or tensile load G (in kN). The shown values comprehend the initial cold ow settling after one day of operation. The nal element deection after the full cold ow compensation (after approx. 1 year) is usually factor x 1,09 higher (depending on specic application, climate...

Open the catalog to page 4

Oscillating Mountings Type AB-HD M AB-HD 27 AB-HD 38 AB-HD 45 AB-HD 50 AB-HD 50-1.6 AB-HD 50-2 AB-HD 27 AB-HD 38 AB-HD 45 AB-HD 50 AB-HD 50-1.6 AB-HD 50-2 Capacity limits by different rpm Dynamic spring value ROSTA blue painted Natural frequency Gmin. – Gmax. [Hz] Values in nominal load range at 960 rpm and sw of 8 mm Nodular cast iron Steel welded construction Load capacity A A* B B* Gmin. – Gmax. un- max. un- max. [N] loaded load loaded load Light metal prole Oscillating Mountings Material structure Please nd elements for higher load capacities on page 2.17. These types can be combined...

Open the catalog to page 5All ROSTA catalogs and technical brochures

-

DO-A

4 Pages

-

DK-A

4 Pages

-

DR-A

4 Pages

-

DK-S

4 Pages

-

DR-C

4 Pages

-

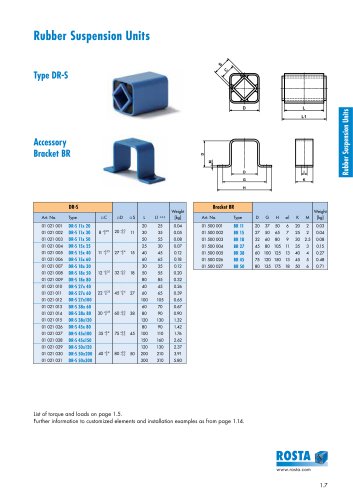

Product Info Type DR-S

4 Pages

-

Green Technology

12 Pages

-

New Motorbase ATEX

8 Pages

-

Product Group Motorbases

16 Pages

-

Type AB TWIN

7 Pages

-

Product Group Tensioner Devices

16 Pages

-

Screen Mounts

20 Pages

-

Double Suspension Type AD-P

5 Pages

-

ROSTA Technology

11 Pages

-

Anti-vibration Mounts

16 Pages

-

TENSIONER DEVICES

16 Pages

-

SCREEN MOUNTS

20 Pages

-

MOTORBASES

16 Pages