Website:

ROSTA

Website:

ROSTA

Catalog excerpts

ROSTA Oscillating Mountings Elastic Suspensions for Screens and Shaker Conveyors High dampening – long lifetime – overload proo

Open the catalog to page 1

ROSTA Oscillating elastic suspensions for all types of screening Oscillating Mountings Rocker arms and drive heads for crank shaft driven shaker conveyors – maintenance-free and long lasting guide arms for shakers – resilient rod heads for alternating loads Spring accumulators for natural frequency shakers – for the powerful, harmonic actuation of feeders – energy-saving and silent power packs Double rocker arms for high speed shaker conveyors – 1 : 1 mass balancing, reaction neutral suspensions – high dynamic spring rates for natural frequency systems

Open the catalog to page 2

Oscillating Mountings machines and shaker conveyors Vibration absorbing mounts for circular and linear motion screens – long lasting – high isolation degree – corrosion-resistant – overload-proof AB Screen Mount AK Universal Joint maintenance-free, long lasting, noiseless, corrosion-resistant and overload-proof for all oscillatory equipments and machinery Universal joint suspensions for gyratory sifters – long lasting articulations for guiding horizontal gyrations – offering extremely high supporting force, up to 40'000 N per mounting

Open the catalog to page 3

Selection table for free oscillating systems (with unbalanced excitation) One mass system circular motion screen Oscillating Mountings AB-HD ABI-HD Page 2.12 One mass system linear motion screen Two mass system with counterframe One mass system linear motion screen hanging Oscillating Mounting – universal mounting. High vibration isolation and low residual force transmission. Natural frequencies approx. 2–3 Hz. 9 sizes from 50 N to 20’000 N per element. Oscillating Mounting for impact loading and high production peaks. (Heavy Duty) Natural frequencies approx. 2.5–4 Hz. 8 sizes from 150 N to...

Open the catalog to page 4

Selection table for guided systems (crank driven) One mass shaker “brute-force” system One mass shaker “natural frequency” system Two mass shaker “fast-runner” system with reaction force-compensation Single Rocker with adjustable length. Models with right-hand and left-hand threads. 7 sizes up to 5’000 N per rocker suspension. Single Rocker with decided center distance. 6 sizes up to 2’500 N for flange fixation. 6 sizes up to 2’500 N for central fixation. Double Rocker with decided center distance. 5 sizes up to 2’500 N for flange fixation. 4 sizes up to 1’600 N for central fixation. Single...

Open the catalog to page 5

Technology of free oscillating systems with unbalanced excitation Oscillating Mountings Introduction Free oscillating systems are either activated in using exciers, t unbalanced motors or unbalanced shafts. The oscillation amplitude, type of vibration and the direction of vibration of the screen are determined by the dimensioning and arrangement of these actuators. The excitation force, the angle of inclination of the excitation, the inclination of the screen-box and the position of the center of g ravity determine the resulting oscillation amplitude of the device. The oscillation...

Open the catalog to page 6

Linear motion screens Linear vibrating screens are preferably mounted on ROSTA oscillating mountings type AB or AB-HD. Depending on the positioning of the exciter on the screening frame, the feed-end: discharge-end load distribution can be different. The feed-end side is normally lighter, as the exciters are positioned close to the discharge-end and thereby pull the material through the screening frame; in many cases, the feed-end: discharge-end distribution is thereby 40% to 60%. In the interest of an even suspension, it is thereby recommended to mount the screening frame on six or more...

Open the catalog to page 7

conveying direction Design layout and evaluation Subject Mass of the empty channel and drive • Example Unit of which approx. 50 % coupling * Total vibrating mass * Mass distribution: feed end discharge end Acceleration due to gravity Load per corner feed end Load per corner discharge end Calculation formulas • Element choice in example Oscillating stroke empty channel Oscillating stroke in operation Motor revolutions Centrifugal force of both drives Oscillating machine factor Machine acceleration • Natural frequency suspensions fe Oscillating stroke (Amplitude peak to peak) Working torque...

Open the catalog to page 8

Technology Determination of the average material conveying speed vm Main influencing factors: – Conveying ability of the material – Height of the bulk goods – Screen box inclination – Position of unbalanced motors – Position of the center of gravity 53 32 Diagram for angle of inclination β = 45° to the horizontal Resonance amplification and continuous running Laboratory measurements of a typical development of the residual forces on a ROSTA screen suspension: vertical force continuous running The horizontal line out of the intercept point of stroke (7.7 mm) and motor revolutions (960 rpm)...

Open the catalog to page 9

Oscillating Mountings Type AB (standard blue) Type ABI (stainless steel) G A A* B B* unmax. unmax. loaded load loaded load 168 Natural frequency Gmin. – Gmax. [Hz] Capacity limits by different rpm 960 min-1 Values in nominal load range at 960 min-1 and sw of 8 mm Dynamic spring value Stainless steel casting ROSTA blue painted Nodular cast iron Steel welded construction Light metal profile Oscillating Mountings Load capacity Gmin. – Gmax. [N]

Open the catalog to page 10

Element heights and cold flow behaviour AB and ABI Approx. height after the first load set-up Approx. height after 1 day Approx. height after 1 year Lowest recommended element height Approx. element height A [mm] Approx. height after the first load set-up Approx. height after 1 day Approx. height after 1 year Lowest recommended element height Approx. element height A [mm] Oscillating Mountings Approx. element height A [mm] Approx. height after the first load set-up Approx. height after 1 day Approx. height after 1 year Lowest recommended element height

Open the catalog to page 11All ROSTA catalogs and technical brochures

-

DO-A

4 Pages

-

DK-A

4 Pages

-

DR-A

4 Pages

-

DK-S

4 Pages

-

DR-C

4 Pages

-

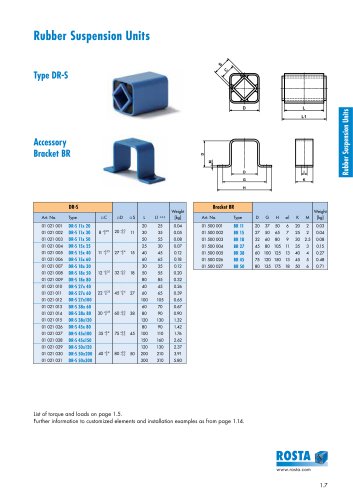

Product Info Type DR-S

4 Pages

-

Green Technology

12 Pages

-

New Motorbase ATEX

8 Pages

-

Product Group Motorbases

16 Pages

-

Type AB TWIN

7 Pages

-

Product Group Tensioner Devices

16 Pages

-

Screen Mounts

20 Pages

-

Double Suspension Type AD-P

5 Pages

-

ROSTA Technology

11 Pages

-

Anti-vibration Mounts

16 Pages

-

TENSIONER DEVICES

16 Pages

-

SCREEN MOUNTS

20 Pages

-

MOTORBASES

16 Pages