Catalog excerpts

ROSTA Anti-vibration Mounts Shock and Vibration absorbing Machine Mounts high degree of isolation – tearproof – absorption of solid-borne nois

Open the catalog to page 1

ROSTA Anti- highly elastical and fully tearproof vibration Anti-vibration Mounts Tearproof suspensions of hanging loads like crane runways, cable car cabines, etc. N Vibration-free installations of motor test arrangements, compressors, etc. long lasting maintenance-free absorbing solid-borne noise

Open the catalog to page 2

vibration Mounts dampers based on torsional rubber pivots Wide range of standardized mounts, for load capacities of 20 –2’000 kg Shock absorbing levelling feet for machine mounting Anti-vibration Mounts Impact-proof suspensions of transfer cradles offering conveyorbelt protection

Open the catalog to page 3

Selection table for Anti-vibration Mounts Type Anti-vibration Mounts for the absorption of tensile, pressure and shear load. Also ESL ideal for wall and ceiling installations. 8 load sizes from 200 N to 19'000 N per mount. Natural frequency between 3,5 – 8 Hz. Mounts are mainly used for overcritical machine installations (machine frequency > mount frequency). Anti-vibration Mounts for the absorption of tensile, pressure and shear load. Also ideal for wall and ceiling installations. 6 load sizes from 300 N to 12’000 N per mount. Natural frequency between 10 – 30 Hz. Mounts can be used for...

Open the catalog to page 4

Technology Anti-vibration Mounts Manufacturers and suppliers of anti-vibration mounts usually offer different types of machine mount with varying natural frequencies to meet the required detuning between the excitation frequency of the machine and the natural frequency of the anti-vibration mount. 1. Isolation of Oscillations and Shocks The vibration technology basically differentiates between two principal types of oscillation appearances (fig. 1 ). Sinusoidal oscillations of working equipments are usually amortised in an overcritical installation manner, shocks and impacts in a...

Open the catalog to page 5

fe = Natural frequency damper [ Hz ] 98 % Diagram of the vibration isolation W [%] At equal values of the excitation frequency and the mount natural frequency an uncontrollable swing-up of machine and damper occurs. In the long run, this appearance will be destructive for machine and mount (fig. 2 ). Anti-vibration Mounts On subcritical installations (fig. 2 ) an anti-vibration mount with high mechanical stiffness and only small deflection behaviours should be chosen, e. g. ROSTA V mounts (high machine stability on mounts). In spite of the fact that the degree of isolation is not definable,...

Open the catalog to page 6

3. Active and Passive Isolation Passive or protective isolation (fig. 7 ) means to install a protective barrier between all kind of existing vibrations and shocks occurring in a factory or workshop towards sensitive installations like e. g. weighing and measuring instruments, laboratory equipment or electronic control units. The vibration technological situations usually vary in each case and are related to environmental situations, too. Often shocks and impacts come from outside, e. g. from motorways, railways, building sites or tooling machines, like punching presses, etc. Generally, the...

Open the catalog to page 7

Anti-vibration Mounts Type ESL Anti-vibration Mounts Natural frequency Gmin. – Gmax. [Hz] Material structure (zinc-plated screws) Load Gmin. – Gmax. [N] on Z-axis Light metal profiles, steel brackets, ROSTA blue painted The max. load on X-axis should not exceed 200 % of the Z-axis capacity. The max. load on Y-axis should not exceed 20 % of the Z-axis capacity. Applicable on tensile, pressure and shear load. Light metal profiles, cast housings, steel brackets, ROSTA blue painted These types can be combined with one another (identical heights and operation behaviour) * compression load...

Open the catalog to page 8

Type ESL Deflection curves and cold flow behaviour Installation guidelines The ESL elements must generally be installed in the same direction. Dynamic forces longitudinal Dynamic forces lateral Wall mounting (Mounting direction should be complied) Applications For active and passive isolation of vibrations and maximum damping of solid-borne noise transmission in weighbridges and scales, measuring systems, control equipment, rotary machinery such as compressors, refrigerating systems, blowers, pumps, mills, mixers, shock-absorbent buffers, etc. Anti-vibration Mounts The below mentioned...

Open the catalog to page 9

Anti-vibration Mounts Type V Alternativ mounting position 180° turned. Anti-vibration Mounts Load Gmin. – Gmax. [N] on X- and Z-axis Natural frequency Gmin. – Gmax. [Hz] Material structure (zinc-plated screws) Light metal profiles, welded steel housings, ROSTA blue painted The max. load on Y-axis should not exceed 20 % of the X- resp. Z-axis capacity. Momentary shock loads of 2.5 g in X- and Z-axis admissible. Applicable on tensile, pressure and shear load. Further information to customized elements and installation examples

Open the catalog to page 10

Anti-vibration Mounts Deflection curves The mentioned deflection values are not suitable for type test- ing. Please consult also our tolerance data in the general cata- logue, chapter "Technology". Installation guidelines Dynamic forces longitudinal Dynamic forces lateral rotary motions. Reduced load ca- e. g. mixer, crusher installation For active and passive isolation of vibrations and damping of solid-borne noise transmission in crushing plants, compressors, _ - .^ga blowers, pumps, rotary converters, generators, mills, crane Kwv mtK \WW/ track supports, etc. ^^^^^^^^^^^B

Open the catalog to page 11

Mounting Feets Type N Type NOX Accessory: Base plate P I Anti-vibration Mounts Natural frequency Gmin. – Gmax. [Hz] Material structure (rubber pad NBR with 50 ShA) zinced, cover blue painted zinced, cover blue painted stainless steel 1.4301 and 1.4305 zinced, cover blue painted stainless steel 1.4301 and 1.4305 Material structure Light metal cast Options by high volume supplies – other thread sizes and lengths – higher load capacities – other painting – imprint of company logo For the isolation of vibrations and solid-borne noise, also for machinery and apparatus requiring levelling, such...

Open the catalog to page 12All ROSTA catalogs and technical brochures

-

DO-A

4 Pages

-

DK-A

4 Pages

-

DR-A

4 Pages

-

DK-S

4 Pages

-

DR-C

4 Pages

-

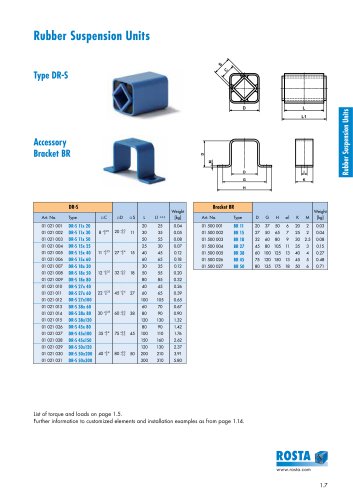

Product Info Type DR-S

4 Pages

-

Green Technology

12 Pages

-

New Motorbase ATEX

8 Pages

-

Product Group Motorbases

16 Pages

-

Type AB TWIN

7 Pages

-

Product Group Tensioner Devices

16 Pages

-

Screen Mounts

20 Pages

-

Double Suspension Type AD-P

5 Pages

-

ROSTA Technology

11 Pages

-

Anti-vibration Mounts

16 Pages

-

TENSIONER DEVICES

16 Pages

-

SCREEN MOUNTS

20 Pages

-

MOTORBASES

16 Pages