Catalog excerpts

Selection table for guided systems (crank driven) One mass shaker “brute-force” system One mass shaker “natural frequency” system Two mass shaker “fast-runner” system with reaction force-compensation Single Rocker with adjustable length. Single Rocker with decided center distance. 6 sizes up to 2’500 N for ange xation. 6 sizes up to 2’500 N for central xation. Oscillating Mountings Models with right-hand and left-hand threads. 7 sizes up to 5’000 N per rocker suspension. Double Rocker with decided center distance. 5 sizes up to 2’500 N for ange xation. 4 sizes up to 1’600 N for central xation. Single Rocker with adjustable length. Models with right-hand and left-hand threads. 7 sizes up to 5’000 N per rocker suspension. Drive Head for crank drive transmission in shaker conveyors. Models with right-hand and left-hand threads. 9 sizes up to 27’000 N per drive head. Spring Accumulator with high dynamic spring value for feeder systems running close to resonance frequency. A spring accumulator consists of 2 DO-A elements. 5 sizes up to dynamic spring value of 320 N/mm. Notes regarding some special shaker systems: – For free oscillating systems on pages 2.16–2.19 – For guided systems on pages 2.31 – 2.33 – For gyratory sifters on page 2.34

Open the catalog to page 1

Technology 1. One mass systems without spring accumulators: Calculation Rocker arms Spring value Oscillating Mountings Drive parameter Length, weight Calculation formulas Trough length Weight empty trough Weight of feeding material Material coupling factor 50% * Weight of oscillating mass * Oscillating machine factor Eccentric radius Stroke Rpm on trough Gravity acceleration Oscillating machine factor Acceleration Total spring value of system Distance between rockers max. 1.5 L max Quantity of rockers 6 z Load per rocker 368 G Selection osc. elements (e. g.) 12× Selection ROSTA-elements:...

Open the catalog to page 2

Technology 3. One mass shaker conveyor systems: Installation instructions Rocker mounting angle β: According to the relevant processing function of the shaker conveyor, the rocker arms are positioned at mounting angles between 10° to 30° in relation to the perpendicular line. (The ideal combination of fast conveying speed with high material throw is given by a rocker inclination angle of 30°.) The power input position of the drive-rod from the eccentric drive should stay at right angles to the rocker arms, this orthogonal positioning offers a harmonic course of the drive system. Screw...

Open the catalog to page 3

Technology 5. Maximum rocker load G, revolutions ns and angle of oscillation α Size (e.g. AU 15) max. load capacity per rocker [N] The angle of oscillation α of each oscillating component (rockers accumulators and drive head) has to be settled within the permissible range (ns and α). Calculation oscillation angle for rockers Eccentric radius R [mm] Center distance A [mm] Oscillation angle α ± [°] Please contact ROSTA for the permissible load indications by higher accelerations and for rocker elements offering higher load capacities. Usually are the revolutions ns between 300 to 600 min -1...

Open the catalog to page 4

Double Rockers AD-P 18 AD-PV 18 AD-P 27 AD-PV 27 AD-P 38 AD-PV 38 AD-P 45 AD-PV 45 AD-P 50 AD-PV 50 Material structure Steel welded constructions, ROSTA blue painted Oscillating Mountings Type AD-PV with inverted ange for frictional center connection Light metal prole Steel welded construction, ROSTA blue painted Material structure Inner square G = max. load in N per rocker, by different K consult chapter 5 on page 2.24. cd = dynamic spring value by oscillation angles α + 5° in speed range of ns = 300–600 min –1 www.rosta.com Further basic information and calculations on pages 2.22–2.24. 2.27

Open the catalog to page 5All ROSTA catalogs and technical brochures

-

DO-A

4 Pages

-

DK-A

4 Pages

-

DR-A

4 Pages

-

DK-S

4 Pages

-

DR-C

4 Pages

-

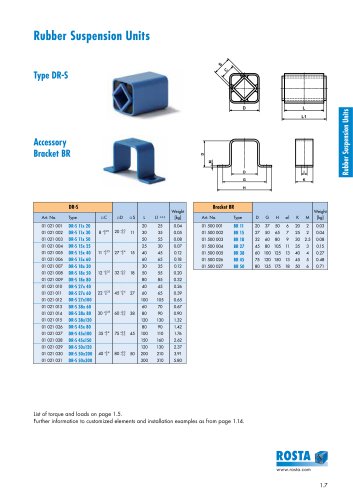

Product Info Type DR-S

4 Pages

-

Green Technology

12 Pages

-

New Motorbase ATEX

8 Pages

-

Product Group Motorbases

16 Pages

-

Type AB TWIN

7 Pages

-

Product Group Tensioner Devices

16 Pages

-

Screen Mounts

20 Pages

-

ROSTA Technology

11 Pages

-

Anti-vibration Mounts

16 Pages

-

TENSIONER DEVICES

16 Pages

-

SCREEN MOUNTS

20 Pages

-

MOTORBASES

16 Pages