Catalog excerpts

DIGEST CATALOG

Open the catalog to page 1

This catalog represents an overview of ROSS’ extensive product line. If you need products or specications not shown within this catalog, please contact ROSS for more information or visit ROSS website at www.rosscontrols.com.

Open the catalog to page 2

Revolutionizing Fluid Power Chevrolet engine tappets, springs, and retainers were the ingredients that Charlie Ross used to make the rst poppet valve after a re destroyed Detroit Seamless Steel Tube Company in 1917. Charlie, a master mechanic, needed to resume production in a hurry and could not wait for shipments of replacement valves from Europe. Soon after, he led his rst patent and in 1921, Charlie Ross, StClair Cameron and four others incorporated the Ross Operating Valve Company. Today, ROSS CONTROLS® proudly continues as a private company owned by the Cameron family and the ROSS...

Open the catalog to page 3

Industry Solutions Visit the ROSS web site at www.rosscontrols.com to fully explore the premium pneumatic and electronic controls systems, services, and distributor channels. ROSS is dedicated to developing matchless pneumatic, electronic, and/or hydraulic system industry solutions to improve the safety and effectiveness of customers’ equipment and operations. Glass Container Machines • • • • • • • • • • • • • • Valves designed for repeatability Counterblow vacuum valves Hi/low pressure valves Plunger up/down & cooling valves Blowhead on/off valve including kickoff Mold open/close valves...

Open the catalog to page 4

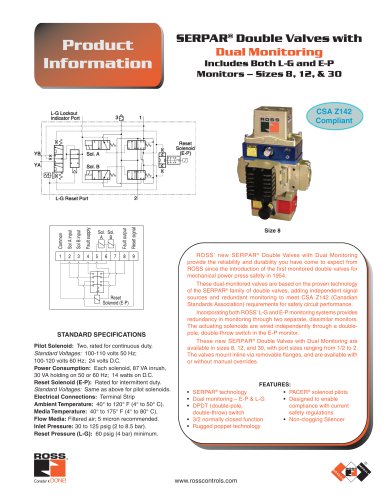

Industry Solutions Safety Products • • • • • • • • • • • • • • • Control Reliable 3/2 and 5/2 pneumatic valves with BG certication Pneumatic internally monitored double valves for safety applications Control Reliable double valves Manual and solenoid L-O-X® valves for energy isolation EEZ-ON® valves for gradual start-up Manual L-O-X® valves with EEZ-ON® operation Modular L-O-X® air entry combination Stainless Steel L-O-X® valves for energy isolation Sensing valves Category 2 In-line valves Pilot operated check valves (single/double channel sensing available) Check valves Safety Clamping...

Open the catalog to page 5

ROSS/FLEX® Process For Innovative Solutions ROSS/FLEX® Is Not a Product Line The ROSS/FLEX® process is a manufacturing culture. Its goal is to help you reduce costs while increasing the practical value of your air controls and pneumatic systems. It puts the power back where it belongs: In the hands of the customer! As a customer, we believe you have every right to receive a product that is precisely suited to your needs - both functional and nancial. If you’re building a machine that requires six different air controls, and the design could be improved by having a single, six-function...

Open the catalog to page 6

ROSS Integrated Systems ROSS Offers Custom Design, Manufacturing and Support of Complete Valve Systems ROSS – Providing more than just components ROSS offers engineering and construction of Valve Stands, Wall Mounted Plates or Enclosed System Panels to allow quick and easy installation at the job site. Services Provided: Systems Engineering Controls Engineering Custom Fabrication Installation Assistance Integrated ROSS Components into a Engineered System Solution Valve Stands Wall or Plate Mounted Systems Free standing valve stands provides a exible way to isolate and position a group of...

Open the catalog to page 7

The ROSS Poppet Valve . . . A ROSS Speciality from the Beginning Positive Sealing Self-Cleaning and Dirt Tolerant Inlet air pressure forces the inlet poppet upward, pushing the poppet seal rmly against the seat. The higher the inlet pressure, the greater the sealing force. Note that the seal is engaged perpendicular to the seat; there is no sliding action to damage and wear the seal, or to cause erratic friction. The ow velocity for a given volume of air is dependent upon the area through which it is owing. The smaller the area, the greater the velocity. In poppet valves, the smallest...

Open the catalog to page 8

Choose the Type of Base Mounted Valve Construction that Best Meets Your Needs Poppet- ISO W64, ANSI W74, SAE 84 Series Poppet surfaces face-seal against at poppet seats. FEATURES • Large pilot pistons • Mechanical detents • Self-cleaning • Short stroke • Fluorocarbon seal option available • Wear-compensating design BENEFITS • Very dependable • Tolerant of dirty air • Positive seating • Fast response • Long service life • Low maintenance • Repeatability Where there is no lubricated air Where the air is dirty (steel mills, glass plants, foundries, and aluminum smelters) High-speed machines...

Open the catalog to page 9

ISO Valves and Serial Bus Communication from ROSS CONTROLS For more information please refer to Please visit the ROSS web site to view the complete Bulletin 600 (Form #A10309) and Bulletin 600T (Form A10309T) at www.rosscontrols.com. © 2013, 5266 CONTROLS®. All Rights Reserved.

Open the catalog to page 10

ISO (15407-1 & 2) Size 00 & 0 Valves Series W66 Specications Flow Capacity: Size 00, Series W66: 0.55 Cv (18 mm) Size 0, Series W66: 1.1 Cv (26 mm) End Caps: PBT (Polybutylene Terephthalate) Fasteners: Zinc Plated Steel Valve Body: Aluminum Coils: Thermoset Plastic Operating Pressure: • Vacuum to 145 psi (10 bar) • Minimum Operating Pressure Size 00 (18 mm) Single Solenoid (5/2) Series W66 (15407-1) • Terminal Block Wiring (Series W66, Size 0 Only) • Collective Wiring – 25-Pin, D-Sub – 19-Pin Round – 16 Point Terminal Strip – M23, 12-Pin – Serial Bus Field Bus Solenoids: • Surge Suppression...

Open the catalog to page 11

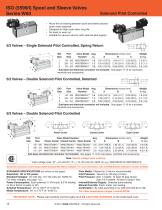

ISO (5599/I) Spool and Sleeve Valves Series W60 Solenoid Pilot Controlled • Micro-thin air bearing between spool and sleeve assures quick valve response • Designed for high cycle rates, long life • No seals to wear out • Suitable for vacuum service (with external pilot supply) 4 2 5/2 Valves – Single Solenoid Pilot Controlled, Spring Return Port Size Valve Model Avg. Number* CV * Sub-base and electrical connector not included. See pages 17-19 for sub-bases, manifolds and accessories. 4 2 5/2 Valves – Double Solenoid Pilot Controlled, Detented Port Size Valve Model Avg. Number* CV * Sub-base...

Open the catalog to page 12All ROSS Controls catalogs and technical brochures

-

safety product

32 Pages

-

Line-Mount Valves

16 Pages

-

DM2

4 Pages

-

MD3

16 Pages

-

CM series

4 Pages

-

Press Industry Solutions

28 Pages

-

DM2 Series D

16 Pages

-

Safety-Related Products

32 Pages

-

Fluid Power Safety Overview

4 Pages

-

Modular Pneumatic Solutions

8 Pages

-

Drip Leg Drains

2 Pages

-

ISO 5599 I and II VDMA 24563

20 Pages

-

Series 80 and 84 SAE Std

12 Pages

-

Series 70 and 74

12 Pages

-

L -O-X ® V a l v es

4 Pages

-

W60

4 Pages

-

foot valves

1 Pages

-

manual valve

12 Pages

-

Pilot operated check valves

12 Pages

-

safety valve

13 Pages

-

FRL ROSS

12 Pages

-

poppet valve

16 Pages

-

TSSA

48 Pages

Archived catalogs

-

ENERGYSAVER® Valve

2 Pages

-

Ross regulators

2 Pages

-

serial bus system

29 Pages

-

Dale series poppet valves

16 Pages