Catalog excerpts

5/2-Way Double Valves with ® CROSSMIRROR® Sensing

Open the catalog to page 1

ROSS safety-related technology has a long tradition... ROSS 5/2-way Double CROSSMIRROR®-Sensing For almost 40 years ROSS has been developing double valves which have made a significant contribution to the operating safety of pneumatically controlled presses. During this period our range of double valves has been developed continuously in response to the needs of press manufacturers and users. Monitoring devices have also been offered in a variety of designs to satisfy different requirements. This all-new ROSS-Crossflow double valve with CROSSMIRis a 5/2-way valve with two individual...

Open the catalog to page 2

5/2-Way Double Valves with CROSSMIRROR®-Sensing SPECIFICATIONS Design: Metal-to-metal spool-andsleeve valves, pressure-operated. Air and spring returned. Operation: Solenoid-operated airpiloted valves, 3/2-way-spring-return. 2) Media : compressed air, dehydrated, filtered (5 µm), lubricated or unlubricated. Operating pressure: 2,5 to 10 bar. Temperature range: 4° C to 50° C. Mounting orientation: preferably vertically. Pilot solenoid: according to VDE 0580. Enclosure rating acc. to DIN 400 50 IP 65. Connector socket according to DIN 43650 Form A. Solenoids rated for continuous duty....

Open the catalog to page 3

5/2-Way Double Valves with CROSSMIRROR®-Sensing Dimensions – Valve with ported sub-base Dimensions – Valve with ported sub-base and pressure switch Dimensional drawings: Mounting interface sub-base to machine dimensions: D; E; F; G and H Dimensions in mm Double valve with ported sub-base ND 10 ND 15 Double valve with ported sub-base and pressure switch ND 10 ND 15

Open the catalog to page 4

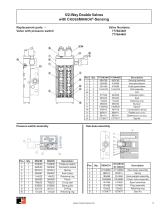

5/2-Way Double Valves with CROSSMIRROR®-Sensing Replacement parts – Valve with pressure switch Pressure switch assembly Description Sensing assembly Inlet spool/sleeve Outlet spool/sleeve Pilot assembly Coil Actuation piston Seal Retaining ring Bumper Spacer Compression spring Gasket (pilot-to-body) Gasket (body-to-sub-base) Seal kit Sub-base assembly Description Pressure switch Connector socket Spring Insert assy. Retaining ring Piston U-cup seal Stem guide O-Ring Retaining ring D1049C91 Description D1153C91 D1048B91 D1130B91 Valve body assembly 488A13 222A13 Spring 185A88 351A88 Valve...

Open the catalog to page 5

5/2-Way Double Valves with CROSSMIRROR®-Sensing Replacement parts – Valve without pressure switch Valve Numbers 7776A3400 7776A4400 Description Sensing assembly Inlet spool/sleeve Outlet spool/sleeve Pilot valve assembly Coil Actuating piston Seal Retaining ring Bumper Spacer Compression spring Gasket (pilot-to-body) Gasket (body-to-sub-base) Seal kit Sub-base assembly D996C91 D1049C91 Description D1153C91 D1048B91 D1130B91 Valve body assembly 488A13 222A13 Spring 185A88 351A88 Valve poppet assembly D332B85 D334B85 Check valve assembly 147A90 147A90 Spool assembly 157A85 157A85 Plug...

Open the catalog to page 6

5/2-Way Double Valves with CROSSMIRROR®-Sensing Flow characteristics (kv-values) kv - values Valve No.: 7776A3400 & 7776A3401 Valve No.: 7776A4400 & 7776A4401 with sub-base D996C91 with sub-base D1049C91 Inlet G 1/2; Outlet G 3/8 Inlet G 3/4; Outlets G 1/2 - G 3/4 Flow direction Normal Function Abnormal Side „A“ Side „B“ Function Abnormal Side „A“ Side „B“ Valve response times Valve No.: 7776A3400 and 7776A3401 5/2 Nominal diameter 10 7776A4400 and 7776A4401 5/2 Nominal diameter 15 Solenoid operated: 230V / 50Hz Test pressure: 3; 6 bar Work ports 2 and 4 are closed without volume. Flow...

Open the catalog to page 7

5/2-Way Double Valves with CROSSMIRROR®-Sensing GENERAL INFORMATION The new ROSS 5/2-way CROSS MIRROR® double valve is designed as a self-monitoring valve. It can be used for controlling pneumatic presses for coldforming of metal (optionally in connection with additional devices such as pilot-operated check valves), if the electric control of the valve is designed in accordance with prEN..."Pneumatic Presses" (June 1998). The mirror-image-type air flow pattern in the CROSS MIRROR® double valve allows an alternating pressure buildup from the de-actuated (pressure port 1 to work port 2) to...

Open the catalog to page 8

5/2-Way Double Valves with CROSSMIRROR®-Sensing CAUTIONS Installation Double valves should be installed only by persons trained and experienced in the installation of such equipment. Lines Air supply directed through air preparation units and pressure regulator to pressure port 1 requires minimum line capacity of pressure port 1. Lines and line connections must be in accordance with relevant safety regulations, e.g. prEN... Pneumatic Presses“ (June 1998). Cylinder speed regulation When installing components between the double valve and the work element, the relevant safety regulations e.g....

Open the catalog to page 9

5/2-Way Double Valves with CROSSMIRROR®-Sensing OPERATING INSTRUCTIONS Start-up Prior to start-up, the installation must be checked thoroughly by persons trained and experienced in the operation of pneumatic equipment. Make sure that the maximum operating pressure specified on the valve label will not be exceeded. When operating pressure is applied, the cylinder piston must move into the atrest-position. For further testing, a functional test as well as a pressure failure test must be performed. Functional test Test 1. Actuate solenoid A 2. Actuate solenoid B 3. Actuate solenoid A, then...

Open the catalog to page 10

5/2-Way Double Valves with CROSSMIRROR®-Sensing MUFFL-AIR® -Silencers A Pipe size R 3/8 R 1/2 R 3/4 Male thread Cautions PRE-INSTALLATION or SERVICE 1. Before servicing a valve or other pneumatic component, be sure that the electrical supply is turned off and that the entire pneumatic system is shut off and exhausted. 2. All ROSS products, including service kits and parts, should be installed and/or serviced only by persons having training and experience with pneumatic equipment. Because any installation can be tampered with or need servicing after installation, persons responsible for the...

Open the catalog to page 11

ROSS EUROPA GmbH Robert-Bosch-Strasse 2 D-63225 Langen / Germany Phone: +49-6103-7597-0 Fax: +49-6103-74694 www.rosseuropa.com ROSS UK Ltd. ROSS CONTROLS P.O. Box 7015, Troy, Michigan 48007 U.S.A. Phone: +1-248-764-1800 Fax: +1-248-764-1850 www.rosscontrols.com Cakemore Road, Rowley Regis, Warley, West Midlands, B65 OQW United Kingdom Phone: +44-121 559 4900 Fax: +44-121 559 5309 www.rossuk.com ROSS ASIA K.K. 10209-5 Tana, Sagamihara-shi Kanagawa-pref. 229-11, Japan Phone: +81-427-78-7251 Fax: +81-427-78-7256 www.rossasia.co.jp ROSS SOUTH AMERICA Ltda. Rua Olavo Goncalves, 43/47 - Centro...

Open the catalog to page 12All ROSS Controls catalogs and technical brochures

-

safety product

32 Pages

-

Line-Mount Valves

16 Pages

-

DM2

4 Pages

-

MD3

16 Pages

-

CM series

4 Pages

-

Press Industry Solutions

28 Pages

-

DM2 Series D

16 Pages

-

Safety-Related Products

32 Pages

-

Fluid Power Safety Overview

4 Pages

-

Modular Pneumatic Solutions

8 Pages

-

Drip Leg Drains

2 Pages

-

ISO 5599 I and II VDMA 24563

20 Pages

-

Series 80 and 84 SAE Std

12 Pages

-

Series 70 and 74

12 Pages

-

L -O-X ® V a l v es

4 Pages

-

W60

4 Pages

-

foot valves

1 Pages

-

manual valve

12 Pages

-

Pilot operated check valves

12 Pages

-

safety valve

13 Pages

-

FRL ROSS

12 Pages

-

poppet valve

16 Pages

-

TSSA

48 Pages

Archived catalogs

-

ENERGYSAVER® Valve

2 Pages

-

Ross regulators

2 Pages

-

serial bus system

29 Pages

-

Dale series poppet valves

16 Pages