Catalog excerpts

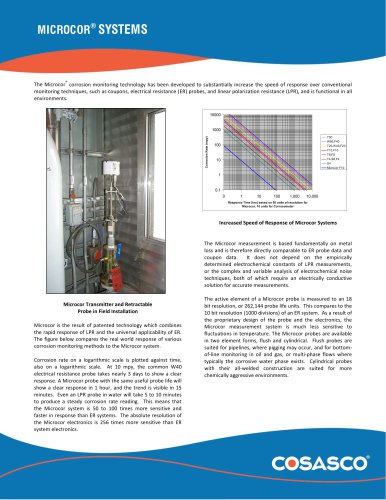

HIGH SPEED ER PROBES Microcor® Probes are an integral component of the new high‐ resolution Microcor system, including the Microcor Wireless Transmitter. Special design of the probes provides advanced thermal performance, and reliable operation in all environments including sour service. Two forms of probe element are available – flush and cylindrical. Several mounting configurations are available, the most common of which allow the probes to be inserted and removed under full process operating conditions without shutdown. M4000 Series Probes The M4000 series probes are called retrievable probes and are designed for use in the Cosasco high pressure access fitting range. This permits probes to be removed or replaced at process conditions up to 6000 psi (400 bar), and temperatures up to 400°F (204°C) with the Cosasco Retriever and service valve. Note: All 4000 series probes must be installed with an overshot adaptor (P/N 126292) to maintain connector cleanliness (see note on back page for details). M3000 Series Probes The M3000 series probes are called retractable probes that can be removed or replaced under full system operating conditions, up to 1500 psi (100 bar) and 425°F (218°C). With high temperature versions this may be extended to 1000°F (520°C) at pressures up to 1000 psi (67 bar). This series uses a sliding stuffing box seal. M2000 Series Probes The M2000 series probes are fixed probes that are used in high pressure, or especially hazardous process streams. However, they cannot be removed or replaced without system shutdown, unless installed in a bypass loop. The Microcor MT‐9485A transmitter and Microcor Wireless Transmitter have to be closely coupled to the probe. This is achieved with a short connecting adapter, so that the transmitter is essentially mounted on the end of the probe. This is the recommended configuration. If conditions prevent this then a short cable of no more than 6 ft. (2 meters) is available. The Microcor technology measures the metal loss that is occurring on the probe element with very high resolution. Consequently, it is useable in virtually any environment, as distinct from electrochemical methods which may only be used in essentially aqueous environments. From the collection of these metal loss readings over time, the corrosion rate can be computed. The very high resolution of the metal loss measurements enable the corrosion rate to be determined in minutes or hours, and provide rapid feedback on changes of corrosion rates, 50 to 100 times faster than other metal loss methods. The high resolution and sensitivity means that you can now obtain rapid response and a long probe life with the standard F10 and T10 probe elements. However, if necessary, other probe element thicknesses are available. The thinner the element, the faster is the response. The thicker the element, the longer is the probe life. Flush Probes are used for best thermal performance where flush mounting with the pipe wall is desirable or essential. A typical example is the bottom‐of‐line locations in oil and gas production pipelines. In these applications, water films commonly collect in the bottom of the line and are the primary cause of corrosion. The flush probe ensures the whole of the probe element is exposed to the water film, whereas a cylindrical probe would only be partially exposed. In other pipeline applications

Open the catalog to page 1

MICROCOR® HIGH SPEED ER PROBES Note: For high velocity process conditions it is recommended that Wake Frequency Calculations be performed – please contact a Cosasco representative for further details. Note: For flush devices which are protruding into the line that may experience high velocity process conditions it is recommended that Wake Frequency Calculations be performed – please contact a Cosasco representative for further details. Optional Shields and Safety Clamps Requires 1” full port ball valve HT = High Temperature ...

Open the catalog to page 2

MICROCOR® HIGH SPEED ER PROBES 0.75” Diameter Head Optional Safety Clamps Requires 1” fullport ball valve Note: For flush devices which are protruding into the line that may experience high velocity process conditions it is recommended that Drag Force Calculations be performed – please contact a Cosasco representative for further details. Note: For flush devices which are protruding into the line that may experience high velocity process conditions it is recommended that Drag Force Calculations be performed – please contact a Cosasco representative for further details. ...

Open the catalog to page 3

MICROCOR® HIGH SPEED ER PROBES Flanged Mounting 1” minimum Optional Shields Max pressure ‐ flange rating, to max 4000 psi (276 bar) Note: For high velocity process conditions it is recommended that Wake Frequency Calculations be performed – please contact a Cosasco representative for further details. Note: For flush devices which are protruding into the line that may experience high velocity process conditions it is recommended that Wake Frequency Calculations be performed – please contact a Cosasco representative for further details. ...

Open the catalog to page 4

Ordering Information Probe Model Number Configuration NOTE: T50 Probes are no longer available. NOTE: Many other alloy options are available. Contact Cosasco for price and availability. Response time to corrosion upset conditions depends on the probe element thickness, the magnitude of the upset corrosion rate and the typical system noise. The adjacent graph shows the typical time required to detect the new corrosion rate trend over the background noise experienced in the real world environment. This is based on 50 Probe Life Units (PLU's) change of the 262,144 PLU's that correspond to the...

Open the catalog to page 5All Rohrback Cosasco Systems catalogs and technical brochures

-

SIDE-STREAM ASSEMBLY

3 Pages

-

RETRACTABLE SYSTEM BIO-PROBE

2 Pages

-

BIO-PROBE

3 Pages

-

Model 6400

4 Pages

-

DCMS®

5 Pages

-

DCHA

6 Pages

-

CORRDATA®

2 Pages

-

WIRELESS SYSTEM

7 Pages

-

MICROCOR® SYSTEMS

4 Pages

-

Electrical Resistance (ER)

4 Pages

-

COSASCO®

3 Pages

-

Cosasco Catalog

492 Pages