Catalog excerpts

WS 5.4600 Workholding Systems SCS clamping against the fixed jaw, mechanically or hydraulically operated jaw widths 80 and 120 mm Advantages ● Compact design ● High precision and accuracy of the m anufactured workpieces by high rigidity ● High zero-point stability ● Sturdy design and good swarf protection ● Large jaw openings ● Extensive range of jaws ● Easy to maintain Application The workholding systems SCS are especially advantageous for 5-axis machining. The compact design allows a good accessibility of the tools to the workpiece. Collision-free tool paths and a 5-sided workpiece machining can be achieved with short standard tools. Due to the good swarf protection, workholding systems SCS are particularly suitable for the use in pallet systems. The stability of the clamping systems and the high retention force due to the use of the special grip reversible jaw with hard metal coating make pre-embossing of the workpieces superfluous. Accessories • Clamping jaws and accessories for mounting, positioning and operation see data sheet WS 5.460Z Application example Description Workholding systems of the SCS series excel by a very compact design. Thanks to the adjusting spindle arranged in the upper part of the housing, deformation in the base during clamping is reduced. All essential components are made of steel. For workholding systems SCS, a wide range of clamping jaws is available (see data sheet WS 5.460Z). Customised versions Workholding systems SCS can also be d elivered as customised versions. For example in other lengths, with individual mounting holes or with holes for a zero point clamping system. Please contact us. Technical data Clamping principle: clamping against the fixed jaw Operation: mechanical with a torque wrench hydraulical with a hydraulic power unit SCS 80 Length of the base: 156 / 200 mm Jaw width: 80 mm Clamping force: 25 kN at 60 Nm Clamping stroke: 35 / 49 mm Max. jaw opening: 159 / 203 mm SCS 80 H Length of the base: 200 mm Jaw width: 80 mm Clamping force: 21 kN at 300 bar Clamping stroke: 4 mm Max. jaw opening: 155 mm SCS 120 Length of the base: 250 / 350 mm 120 mm Jaw width: 40 kN at 100 Nm Clamping force: Clamping stroke: 60 / 116 mm Max. jaw opening: 200 / 300 mm SCS 120 H Length of the base: 250 mm 120 mm Jaw width: 37.5 kN at 300 bar Clamping force: Clamping stroke: 4 mm Max. jaw opening: 200 mm Versions Mechanically operated The movable clamping jaw is displaced by a threaded spindle which is also used to build-up Consultation the clamping force. Our experts will be pleased to advise you also A torque wrench is used for exact and reproducon site, and work with you to find the optimum ible clamping force adjustment. clamping solution. Extensive information such as drawings and Hydraulically operated Hydraulically operated versions are single CAD models are available on request. acting. Clamping is effected by hydraulic pressure, unclamping by spring force. *Important note The specified clamping forces apply to a clamping height (n) of 30 mm. For higher clamping heights, the clamping forces are reduced. ROEMHELD · 927 Horan Drive, Fenton, MO 63026 · Phone: (314) 386-8022 · Fax: (314) 386-8034 · info@clrh.com Actual issue see w

Open the catalog to page 1

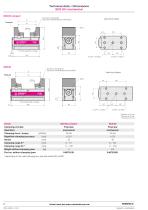

Technical data • Dimensions SCS 80 mechanical SCS 80 compact Accessory: Clamping jaw (Fig. shows reversible step jaw 9 4672 6903) View from below on both sides M 6 x 10 deep 80 Accessory: Clamping jaw (Fig. shows reversible step jaw 9 4672 6903) View from below on both sides M 6 x 10 deep 4x M 10 x 15 deep * Tolerance ±0.01 mm ** Tolerance ±0.02 mm Dimensions in [mm] Clamping principle Operation Repetitive clamping accuracy Clamping force / torque Clamping range S 1) Clamping range S1 1) Weight without clamping jaws Part no. without clamping jaws 1) depending on the used clamping jaw, see...

Open the catalog to page 2

Technical data • Dimensions SCS 120 mechanical SCS 120 compact Accessory: Clamping jaw (Fig. shows reversible step jaw 9 4673 6903) View from below on both sides M 8 x 15 deep Accessory: Clamping jaw (Fig. shows reversible step jaw 9 4673 6903) View from below on both sides M 8 x 15 deep * Tolerance ±0.01 mm ** Tolerance ±0.02 mm Dimensions in [mm] Clamping principle Operation Repetitive clamping accuracy Clamping force / torque Clamping range S Weight without clamping jaws 1) Part no. without clamping jaws 1) depending on the used clamping jaw, see data sheet WS 5.460Z

Open the catalog to page 3

Technical data • Dimensions SCS 80 / 120 hydraulic SCS 80 H S Fixed jaw View from below Accessory: Clamping jaw (Fig. shows reversible step jaw 9 4672 6903) Hydraulic port at the bottom for plug-type connector 8 0530 0023 on both sides M 6 x 10 deep View from below Accessory: Clamping jaw (Fig. shows reversible step jaw 9 4673 6903) Hydraulic connection at the front G¼ Hydraulic port at the bottom for plug-type connector 8 0530 0023 on both sides M 8 x 15 deep Hydraulic connection at the front G¼ * Tolerance ±0.01 mm ** Tolerance ±0.02 mm Dimensions in [mm] Hydraulic connection optionally...

Open the catalog to page 4All ROEMHELD NORTH AMERICA catalogs and technical brochures

-

Stark Speedy Classic

84 Pages

-

drop_zero

4 Pages

-

Box jaws

4 Pages

-

WS 4.3301

3 Pages

-

WS 4.3302

4 Pages

-

WS 4.5500

6 Pages

-

WS 7.3540

2 Pages

-

WS 3.3800

2 Pages

-

VarioLine

12 Pages

-

Double clamping system DF

8 Pages

-

HILMA DS

8 Pages

-

HILMA KNC

12 Pages

-

WS 1.3080

4 Pages

-

WS 1.3070

4 Pages

-

WS 1.3020

2 Pages

-

WS 5.4502

4 Pages

-

WS 5.3570

4 Pages

-

WS 5.4501

2 Pages

-

STARK.easyclick

13 Pages

-

B 1.849 Compact Swing Clamps

4 Pages