Website:

RÖHM GmbH

Website:

RÖHM GmbH

Catalog excerpts

THE DURO-A RC. FROM RÖHM. INNOVATIVE TECHNOLOGY DESIGNED TO DRIVE YOU FORWARD

Open the catalog to page 1

THE DURO-A RC. FROM ROHM. DESIGNED FOR Automatic clamping on machines for changing geometries The DURO-A RC is a three-jaw chuck with through-hole and quick jaw change system, which can be clamped automatically, i.e. hydraulically by a CNC machine. RC stands for rapid change and A for automatic. It is primarily used for rotary machining of cylindrical and disk-shaped blanks with frequently changing part geometries. It outperforms similar products thanks to the very fast jaw change, short cycle times and high speeds, making it especially well suited for flexible use in automated production....

Open the catalog to page 2

KEEP THE FORCE ON The power chuck with quick jaw change that has no idle stroke and therefore cuts your manufacturing costs There are quick jaw change chucks where nothing happens for the first few millimeters when opening or closing. And then REDUCING THE DEAD WEIGHT BY UP TO 6 KG there’s the DURO-A RC. Which responds immediately. The RÖHM designers have quite simply eliminated the dreaded “idle stroke”. All components are continuous engaged, which means that, when pulling or pushing, the cylinder starts to open or close the jaws immediately. And because you are interested in efficient...

Open the catalog to page 3

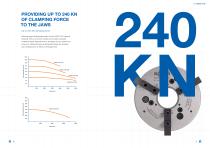

PROVIDING UP TO 240 KN OF CLAMPING FORCE TO THE JAWS Up to 240 kN clamping force Clamping means holding things steady. And the DURO-A RC is great at doing that. With up to 240 kN, the lathe chuck holds the clamped workpieces steady. High performance. Something for your machine tool to live up to. High performance is emphasized through the minimized loss of clamping force to effects of centrifugal forces. Total clamping force kN Total clamping force kN

Open the catalog to page 4

36 MONTHS IS NO BIG DEAL FOR RÖHM 36 month warranty I’m sorry, did you say that RÖHM offers a 36 month FINISH TIME UNDER 60 SECONDS warranty on the DURO-A RC? This will only be a surprise to those who have never used a RÖHM product before. Because there's one thing you hear a lot in production: “RÖHM? They last forever!”. That’s why it's no big deal ENSURING THE FORCE GETS TO WHERE IT IS NEEDED RÖHM jaws. In any situation. The jaws are even closer to the workpiece than the For faster jaw changes The jaws on the DURO-A RC can be individually moved, for us to provide a 36 month warranty for...

Open the catalog to page 5

Jaw length [mm] Jaw width [mm] Jaw length [mm] Jaw width [mm] 65 20 Jaw length [mm] Jaw width [mm] Jaw length [mm] Jaw width [mm] Jaw length [mm] Jaw width [mm] Reversible top jaws HARDENED External clamping Internal clamping External clamping Internal clamping External clamping Internal clamping

Open the catalog to page 6

Unstepped top jaw AB, standard design External clamping Internal clamping Jaw length [mm] Jaw width [mm] Jaw height [mm]

Open the catalog to page 7

One-piece reversible jaw HARDENED External clamping Internal clamping External clamping Internal clamping External clamping Internal clamping External clamping Internal clamping External clamping Internal clamping

Open the catalog to page 8

Block jaws, guide hardened and ground External clamping Internal clamping Jaw length [mm] Jaw width [mm] Jaw height [mm]

Open the catalog to page 9

Internal clamping External clamping Internal clamping External clamping Internal clamping External clamping Internal clamping Standard width, small clamping range Standard width, medium clamping range Tongue and groove, small clamping range Standard width, large clamping range Tongue and groove, medium clamping range Wide version, small clamping range Wide version, medium clamping range Tongue and groove, large clamping range Wide version, large clamping range

Open the catalog to page 10

IF YOU ARE LOOKING FOR SOMETHING SPECIAL Custom jaws Because we have been producing them for decades at ROHM there are countless possibilities for custom jaws. There are hardly any jaw geometries that we have not already produced for a machining specialist of some kind. And if we haven't produced your geometry yet, give us the challenge. Customer-specific special jaw for interior and exterior machining of thin-walled aluminum tubes Customer-specific special jaw for interior and exterior machining of thin-walled aluminum housings Customer-specific pendulum jaw with interchangeable clamping...

Open the catalog to page 11

INSTALLATION HOW IS THE DURO-A RC MOUNTED ONTO THE SPINDLE ON YOUR MACHINE TOOL? DATUM EDGE FOR CONCENTRICITY MEASUREMENT A datum edge is worked into the rear section of the chuck. Here, a dial gage can be used to check the concentricity of the chuck on your machine tool. 22 The DURO-A RC is available with two different mounting types. The mounting is integrated directly into the body of the chuck, which means that no additional adapter plates are required. Multiple machines with different spindle mountings? Then choose the DURO-A RC with adapter recess and also get yourself an adapter with...

Open the catalog to page 12

THE MATCHING CLAMPING CYLINDER. FROM ROHM. At ROHM, we view clamping technology as a system. A high performance lathe chuck includes an equally high performance cylinder. ROHM supplies the Forto-H cylinder without a through hole and the hollow clamping version from the Forto-HT series. The connection to the clamping cylinder is made using a tensile connection. This tensile connection is always customized and is configured based on the cylinder - clamping device - machine tool combination. We are happy to support you in designing and producing an appropriate tensile connection for your...

Open the catalog to page 13

HOW THE DURO-A RC FROM RÖHM WORKS opposite direction. For what is known as internal ances ensure precision. Towards the head stock, clamping, i,e, clamping of parts from inside, for the spindle connection (5) is the final piece of the example rings for machining on the outside, the chuck. It has screws and an adapter recess (op- To clamp a workpiece, the cylinder is moved in the the DURO-A RC and protects them. Minimal toler- The steel base body (1) holds the components of process is the exact reverse. The protective sleeve tional: short taper) to produce a load-carrying and (7) prevents...

Open the catalog to page 14All RÖHM GmbH catalogs and technical brochures

-

Lathe chucks - independent chuck

53 Pages

-

THE DURO-A.

15 Pages

-

Lubrication device LUBRITOOL

4 Pages

-

BOHRFUTTER

44 Pages

-

AUTOMATION TECHNOLOGY Catalogue 2018

132 Pages

-

VICES Catalogue 2019

152 Pages

-

Lathe Chuck DURO-M

53 Pages

-

LIVE CENTRES FACE DRIVERS

68 Pages

-

SUPRA SK

2 Pages

-

SUPRA SK E

2 Pages

-

Vices Operation guide

6 Pages

-

PRIMA-S / -M

1 Pages

-

Pro - standard design

1 Pages

-

NEW RÖHM On-Site Service

2 Pages

-

NEW RÖHM Services

6 Pages

-

NEW RÖHM Product summary

12 Pages

-

RÖHM VICE NOVELTIES

8 Pages

-

ZS-ZSU

2 Pages

-

MKS

1 Pages

-

SPIRO - SPIRO-SK

1 Pages

-

SUPRA-SK E

1 Pages

-

QUICK-ACTION DRILL CHUCKS

6 Pages

-

Automotive special designs

4 Pages

-

e-Cylinder EHS & EVS

8 Pages

-

Swivel units RSP

8 Pages

-

Synthetic gripper RRMP

4 Pages

-

Oil and Gas

24 Pages

-

micro technology

24 Pages

-

Machining of Large Parts

8 Pages

-

3/2 jaw chucks DURO-NC

2 Pages

-

DURO-TA XT KEY BAR CHUCK

8 Pages

-

Clamping jaws catalogue

148 Pages