Catalog excerpts

DATA SHEET SP3D01_07 Issue 7, 25th October 2023 SpinCoTM Incremental Magnetic Encoder System SPINDLE ENCODER SpinCo is an incremental magnetic encoder system designed for use as primary position and speed feedback sensor for machine tool spindles. HIGH SPEED It consists of two key elements, a readhead and a magnetic ring. RLS proven AMR and GMR sensor technologies are used for sensing magnetized pattern on the magnetic ring to ensure accurate and reliable operation over the entire operating range. ROBUST DESIGN Signal stability From 50 to 556 sin/cos periods per revolution ABZ digital incremental outputs with up to 4,096 steps per sin/cos period Wide installation tolerances Small readhead size Analogue output signals (1 Vpp) High accuracy INDUSTRIAL AUTOMATION HARSH ENVIRONMENT MOTOR CONTROL

Open the catalog to page 1

General information The encoder continuously calibrates the sensed signals to ensure accurate and reliable output signals, which are reported as industry standard 1 Vpp analogue incremental signals. The magnetic ring consists of an elastoferrite layer firmly bonded to a stainless steel hub. The elastoferrite layer is magnetised with alternating magnetic poles. The poles can be 1 mm or 2 mm long. To ensure safety and reliability even at the highest rotational speeds, all magnetic rings have a fully welded cover foil. This thin steel layer protects the elastoferrite from damage and the...

Open the catalog to page 2

Storage and handling Storage temperature Operating temperature ߌ High resistance to humidity HANDLE WITH CARE. This encoder system is a high performance metrology product and should be handled with the same care as any other precision instrument. The use of industrial tools such as hammers and chisels or exposure to strong magnets such as a magnetic base is unacceptable and carries the risk of irreparable damage to the product. The magnetic ring should not be exposed to magnetic field densities higher than 25 mT on its surface, as this can damage the ring. Exposure to external magnetic...

Open the catalog to page 3

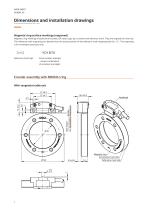

Dimensions and installation drawings Dimensions and tolerances are in mm. Magnetic ring surface markings (engraved) Magnetic ring markings include serial number, QR code, logo, part number and reference mark. They are engraved on the hub. The reference mark engraving can deviate from the actual position of the reference mark magnetization for ±5 °. The engraving is for orientation purposes only. YD1B70 Reference mark sign Serial number example - unique combination of six letters and digits Encoder assembly with MR063U ring With tangential cable exit 37 ±0.2 16.5 ±0.2 Ride height Magnetic...

Open the catalog to page 4

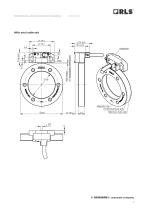

Dimensions and installation drawings With axial cable exit 37 ±0.2 Ride height Magnetic ring Incremental track side 4.5 ±0.5 Reference mark side Pole length

Open the catalog to page 5

Dimensions and installation drawings Technical features Maximum speed Refer to Maximum speed calculator

Open the catalog to page 6

Dimensions and installation drawings Technical features Pole length (mm) Maximum speed Refer to Maximum speed calculator Moment of inertia (kgmm )

Open the catalog to page 7

Dimensions and installation drawings Technical features Pole length (mm) Maximum speed Refer to Maximum speed calculator Moment of inertia (kgmm )

Open the catalog to page 8

Dimensions and installation drawings Technical features Pole length (mm) Maximum speed Refer to Maximum speed calculator Moment of inertia (kgmm )

Open the catalog to page 9

Dimensions and installation drawings Technical features Pole length (mm) Maximum speed Refer to Maximum speed calculator Moment of inertia (kgmm )

Open the catalog to page 10

Dimensions and installation drawings Technical features Pole length (mm) Maximum speed Refer to Maximum speed calculator Moment of inertia (kgmm )

Open the catalog to page 11

Dimensions and installation drawings Technical features Pole length (mm) Maximum speed Refer to Maximum speed calculator Moment of inertia (kgmm )

Open the catalog to page 12

Dimensions and installation drawings Technical features Pole length (mm) Maximum speed Refer to Maximum speed calculator Moment of inertia (kgmm )

Open the catalog to page 13

Dimensions and installation drawings Technical features Pole length (mm) Maximum speed Refer to Maximum speed calculator Moment of inertia (kgmm )

Open the catalog to page 14

Dimensions and installation drawings Maximum speed Refer to Maximum speed calculator Magnetic ring Incremental track side Reference mark side See the encoder assembly on the follo

Open the catalog to page 15

Dimensions and installation drawings Encoder assembly with MR176X ring 37 ±0.2 4.3

Open the catalog to page 16

Installation instructions Installation of magnetic rings Machine the mounting shaft according to the dimensions given in the table below. Dimensions and tolerances are in mm. Shaft diameter (clearance fit installation, fasteners, gluing) - Ds Shaft outer diameter (press fit or shrinkage press fit) - Dspd 20 r6 Installation by press-fitting Slip the ring onto the mating shaft applying equal or uniform force along the whole ring circumference. Shaft* Magnetised ring

Open the catalog to page 17

Installation with fasteners 1. 2. Slide the ring onto the mating shaft. Attach the ring with appropriate fasteners. Magnetised ring Shaft* Magnetised ring See table of recommended tightening torques for RLS products (document TTD01) available at RLS media center. * Not provided. ** For the depth of the groove, please check the specifications of the adhesive. Shaft* Magnetised ring Magnetised ring

Open the catalog to page 18

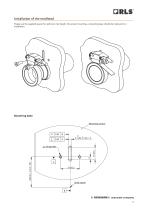

Installation of the readhead Please use the supplied spacer for optimum ride height. For proper mounting, a mounting base should be made prior to installation. Drawing created. Mounting base Mounting surface Shaft center

Open the catalog to page 19

Installation tolerances (readhead to ring) Radial displacement (ride height) 1 mm pole length 2 mm pole length Axial displacement Tangential displacement of the sensor Non-parallel mounting (roll) Non-parallel mounting (pitch) Magnetic ring

Open the catalog to page 20

Technical specifications System data Pole length Less than 1 electrical degree Less than ±2 counts for maximum interpolation factor and less than unit of resolution for all other interpolation factors Electrical data Supply voltage 5 V ±10 % (absolute maximum 6 V) Reverse polarity and overvoltage protected Current consumption Set-up time Mechanical data Mass Readhead: 120 g (1 m cable, no connector) Coefficient of thermal expansion (CTE) of steel hub of the ring (ppm/°C) Environmental data Temperature Environmental sealing * IP protection is only guaranteed when suitable connector with same...

Open the catalog to page 21All RLS catalogs and technical brochures

-

ArtosTM_DBD01_05

21 Pages

-

Artos_DRD01_03

21 Pages

-

RE58_RE58D04_04

22 Pages

-

RE22_RE22D01_10

9 Pages

-

RM22_RM22D01_05

9 Pages

-

MR_MR01D01_06

55 Pages

-

MR_MR02D02_04

41 Pages

-

LM13_LM13D01_13

17 Pages

-

LM10 Series

20 Pages

-

AksIM-2_MBD07_05

14 Pages

-

RE16 / RM16

15 Pages

-

AksIM-2_MBD01_11

53 Pages

-

FlexINTM

2 Pages

-

OnAxis™ Redundant_RDD01_01

14 Pages

-

Orbis™

2 Pages

-

DRD01_03

21 Pages

-

SARD01_02

15 Pages

-

ArtosTM_DBD01_05

21 Pages

-

MS Incremental Magnetic Scales

26 Pages

-

AksIM-4

14 Pages