Catalog excerpts

DATA SHEET MBD01_11 Issue 11, 6th May 2024 AksIM-2 Off-Axis Rotary Absolute Magnetic Encoder HIGH ACCURACY HIGH SPEED AksIM-2 is a non-contact, high performance off-axis absolute rotary encoder designed for integration into applications with limited space. A hollow ring, true absolute functionality and high-speed operation make this encoder suitable for many applications. The AksIM-2 encoder system consists of an axially magnetised ring and a readhead. The encoders are equipped with BiSS, Asynchronous serial (UART), SPI, PWM or SSI communication interfaces and offer a range of binary resolutions up to 20 bits per revolution. MULTITURN COUNTER True absolute system Multiturn counter option Custom magnetic sensor ASIC High speed operation Self-calibration option High repeatability COLLABORATIVE ROBOTS ROBOTIC JOINTS

Open the catalog to page 1

General information The AksIM-2 encoder operates in a temperature range between -40 °C and +105 °C and is highly resistant to shock and vibration. It has a built-in advanced self-monitoring function that continuously checks several internal parameters. Error reports, warnings and other status signals are available on all communication interfaces and visualised with the on-board LED. The AksIM-2 encoder system is suitable for use in industrial and medical applications. A typical application is a robotic arm joint with a cable feed through the ring, or a precision gearbox where the ring is...

Open the catalog to page 2

Storage and handling Storage temperature Operating temperature HANDLE WITH CARE. This encoder system is a high performance metrology product and should be treated with the same care as any other precision instrument. Use of heavy duty industrial tools or exposure to strong magnets, such as a magnetic base, is unacceptable and risks of irreparable damage to the product. The magnetic ring should not be exposed to magnetic field densities higher than 50 mT on its surface, as this can damage the ring. Please see Chemical resistance or contact RLS. Readhead is ESD sensitive - handle with care....

Open the catalog to page 3

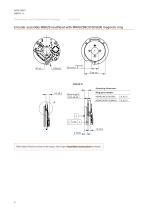

Dimensions and installation drawings Dimensions and tolerances are in mm. MB022 readhead with MRA022HP008DMN00 magnetic ringMRA022HP008DMN00 Encoder assembly MB022 readhead with magnetic ring Detail A Mounting dimension 6.3 ±0.15 6.2 ±0.3 Ride height influences noise on the output. See chapter Installation instructions for details.

Open the catalog to page 4

Dimensions and installation drawings Press-fit mounting to shaft D8: recommended shaft OD tolerance is r6 (+0.019 / +0.028)

Open the catalog to page 5

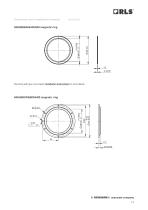

Dimensions and installation drawings Encoder assembly MB029 readhead with MRA029BC010DSE00 magnetic ring 0RXQWLQJGLPHQVLRQ Mounting dimension: 0's Ring part number 'HWDLO$ Ride height influences noise on the output. See chapter Installation instructions for details.

Open the catalog to page 6

Dimensions and installation drawings s s Press-fit mounting to shaft D12.7: recommended shaft OD tolerance is p7 (+0.018 / +0.036)

Open the catalog to page 7

Dimensions and installation drawings Encoder assembly MB039 readhead with MRA039BC020DSE00 magnetic ring Ride height influences noise on the output. See chapter Installation instructions for details.

Open the catalog to page 8

Dimensions and installation drawings MRA039BC020DSE00 magnetic ring [)RUIDVWHQHUV 0,62

Open the catalog to page 9

Dimensions and installation drawings Encoder assembly MB049 readhead shape D and readhead shape E with MRA049BC025DSE00 magnetic ring Ring part number Ride height influences noise on the output. See chapter Installation instructions for details.

Open the catalog to page 10

Dimensions and installation drawings

Open the catalog to page 11

Dimensions and installation drawings * Also possible with suitable M2. Mounting with glue. See chapter installation instructions for more details.

Open the catalog to page 12

Dimensions and installation drawings 0%UHDGKHDGVL]H( ZLWK05$%&'6(ULQJ 0%UHDGKHDGVL]H( Encoder assembly MB053 ZLWK05$%&'6(ULQJ magnetic ring readhead shape E with MRA053BC030DSE00 r 'HWDLO$ Ride height influences noise on the output. See chapter Installation instructions for details. 'HWDLO$

Open the catalog to page 13

Dimensions and installation drawings * Also possible with suitable M2. Mounting with glue. See chapter Installation instructions for more details.

Open the catalog to page 14

Dimensions and installation drawings Encoder assembly MB064 readhead shape D with MRA064BC040DSE00 magnetic ring 'HWDLO$ Ride height influences noise on the output. See chapter Installation instructions for more details.

Open the catalog to page 15

Dimensions and installation drawings * Also possible with suitable M2.

Open the catalog to page 16

Dimensions and installation drawings Encoder assembly MB080 readhead with MRA080BC055DSE00 magnetic ring Ring part number Ride height influences noise on the output. See chapter Installation instructions for more details.

Open the catalog to page 17

Dimensions and installation drawings * Also possible with suitable M2.

Open the catalog to page 18

Dimensions and installation drawings Mounting with glue. See chapter installation instructions for more details.

Open the catalog to page 19

Installation instructions Axial position adjustment (ride height) The distance between the sensor and the ring should be between 0.05 mm and 0.35 mm. See detail A on dimension drawings of encoder assemblies. Using the gold-plated surface on the bottom as a reference surface for mounting the readhead is recommended. If the top side of the readhead is used as a reference surface, note that the thickness tolerance of the readhead must be taken into account. Also make sure that the signal traces and components are not in contact with mechanical assembly. Optionally, you may also use shims for...

Open the catalog to page 20

Installation tolerances (ring to shaft) Ring / shaft fit After self-calibration See table of recommended tightening torques for RLS products available at RLS media center. Mounting rings with glue (option “G” in part number) Rings that can only be mounted with glue: MRA049BG034DSN00, MRA053BG040DSN00 and MRA080BG064DSN00. It is possible to install any type of AksIM-2 ring with glue. However, RLS does not recommend or supply any type of glue. Contact a local company that sells glue for further help in selecting the correct glue type. When choosing the correct type of glue, consider the...

Open the catalog to page 21

Electrical connections Asynchronous serial Soldering pads * See chapter External isolated temperature sensor 8-pin low profile connector FCI / AMP 10114830-11108LF -horizontal FCI / AMP 10114828-11108LF -vertical (readhead MB022 only) Note: On some connectors there is “Pin 1” marking imprinted, which is sometimes in a wrong position and must be ignored. Counterpart mating connector: FCI / AMP 10114826-00008LF and 10114827-002LF Soldering pads Dimensions: 2.54 x 1.14 mm with 1.875 mm pitch Locking features of the connector: Retention system on the bottom side - bumps on the plug and dimples...

Open the catalog to page 22All RLS catalogs and technical brochures

-

ArtosTM_DBD01_05

21 Pages

-

Artos_DRD01_03

21 Pages

-

RE58_RE58D04_04

22 Pages

-

RE22_RE22D01_10

9 Pages

-

RM22_RM22D01_05

9 Pages

-

MR_MR01D01_06

55 Pages

-

MR_MR02D02_04

41 Pages

-

LM13_LM13D01_13

17 Pages

-

LM10 Series

20 Pages

-

AksIM-2_MBD07_05

14 Pages

-

RE16 / RM16

15 Pages

-

SpinCoTM_SP3D01_07

31 Pages

-

FlexINTM

2 Pages

-

OnAxis™ Redundant_RDD01_01

14 Pages

-

Orbis™

2 Pages

-

DRD01_03

21 Pages

-

SARD01_02

15 Pages

-

ArtosTM_DBD01_05

21 Pages

-

MS Incremental Magnetic Scales

26 Pages

-

AksIM-4

14 Pages