Catalog excerpts

BEAHINC IMOUSTRIES TQOS MAINTENANCE In order to get the maximum bearing rating life, a good sealing system is required together with the correct lubricant. This small guide intends to give proper guidelines for maintenance of TQOS bearings (sealed four-row taper roller bearings). This bearing design features a seal set equipped on the side flanges and on the cone spacer. In greater detail, the seals on the different bearing components are as follows: • O-Rings, located on the outer diameter and working with the housing; • double lip seal, located on the inner diameter and working on the cones; • O-Ring, installed on both cones. Whichever seal set is installed on the TQOS, its main purpose is to: • isolate the bearing from external contaminants (water, dust, etc.), which can compromise the correct operation; • prevent lubricant pollution; • retain within the bearing the correct amount of lubricant, estimated by RKB Technical Department according to the information supplied by the customer, in order to allow the elastohydrodynamic lubrication condition. Executive Headquarters and Technological Center P.O. Box 169 ■ 6830 Chiasso 3 info@rkbeurope.com • www.rkbbearings.com TECHNOLOGICAL BEARINGS

Open the catalog to page 1

The two flanges are provided with one O-Ring on the outer diameter and one double lip seal on the inner The seal on the outer diameter is an O-Ring type, which works in static or semi-static conditions. If the inner diameter of the O-Ring is a little larger than the groove on the flange, it can be resized according In order to appropriately stick the O-Ring terminals, a proper glue, selected according to application temperature and seal rubber, has to be used (in case of doubts, please contact RKB Technical Department: ttu@rkbeurope.com). Before gluing, it is mandatory to carefully clean...

Open the catalog to page 2

Inner ring The most common sealing system designs for the inner ring are: anti-vortex type and O-Ring type. Anti-vortex design Before mounting the anti-vortex system, properly lubricate the whole cone surface and the O-Ring, so that, when the cone spacer is mounted on the cone, the seal lip can slide more easily. If the customer wants to fix the seal on the spacer, he can use a proper glue, selected according to bearing working temperature and glue capacity not to alter seal material characteristics. The same applies to O-Rings. For example, if the temperature is less than 110 °C the...

Open the catalog to page 3All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

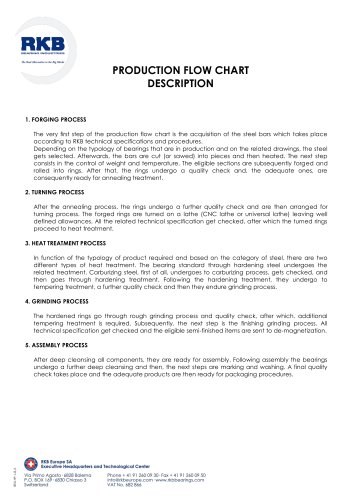

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages