Catalog excerpts

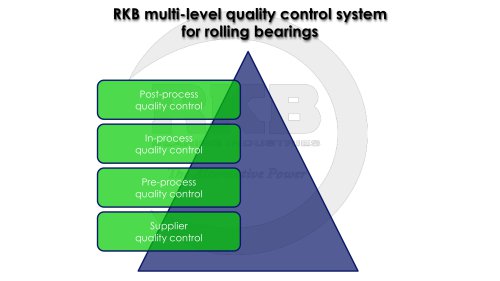

SUPPLIERS PROFILE Technological and “tailor made With a business model based on a vertically integrated organization, which goes from the provisioning of raw materials up to the after sales service, Rkb Group intends to be a reference partner in the design, manufacture and supply of high added value bearings. Cinthya Piannell ver 70 years of history behind, more than 700 employees working in direct branches and in the various productive units, resulting in a diffused presence in more than 50 Countries in the world. These are the figures that identify Rkb, important industrial Group headquartered in Balerna (Switzerland) and operating in the sector of the production of technological bearings with high added value, executions that find the widest application both in the original equipment market (OEM), and in spare part one (MRO). «In our headquarters in Balerna – specifies Riccardo Dell’Aquila, business development manager – are concentrated all basic competences and the critical activities of our Group, from design to engineering, from research and development to quality control. A strategic choice that allows managing flexible procedures and protocols, targeted to the highest optimization of each job order, with great interdisciplinarity among all the technical roles involved in the product development process ». An approach, this one, recognizable in the whole production and ascribable to the main families of rolling bearings (with Andrea Fiore, technical team unit coordinator of Rkb. balls or cylindrical tapered and spherical rollers), subdivided into the main segments of: miniature and small size precision ball bearings, up to 35 mm of inner diameter; standardized bearings up to an outer diameter of 1,925 mm; technological and optimized bearings for the specific application. «Even if there is a range of bearings defined “standard” – adds Dell’Aquila – our strong point undoubtedly resides in the constant technological upgrading accomplished, targeted to the full satisfaction of the qualitative and performance requisites coming from the market for specific “tailor made” applications». This is made possible not only by the significant R&D activity carried out (to whose department about 10% of the turnover is yearly destined), but also by the fact that Rkb holds the complete control of the whole production chain, starting from the provisioning of raw materials, with a pro- Rkb multiroll bearing for aluminum rolling mill, optimized for air-oil lubrication and automatic roll changing device. ductive capacity that exceeds 350 tons of steel machined every month, able to face the various market demands. «Market that by 20% of our turnover – adds Dell’Aquila – is intended for Italy, while the remaining part can be subdivided among the Old Continent and key areas especially in USA, Brazil, Taiwan and South-East Asia Countries. Historical markets, then, with the addition of rising Countries where there are margins of further growth». A constant growth, despite the not so favourable general period, confirmed also for the current year.

Open the catalog to page 1

e” rolling BEARINGS A double-figure positive trend completed also by the imminent inauguration of a new productive site in China. Product efficiency and quality Sealed four-row tapered roller bearing for work rolls of hot stripping mill for flat products, with optimized profile, contact seals for contamination exclusion and grease lubrication, and phosphating treatment to increase the resistance to corrosion in aggressive environments. «The new productive factory MS Plant – specifies Andrea Fiore, technical team unit coordinator – develops on 4 floors for Riccardo Dell’Aquila, business...

Open the catalog to page 2All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

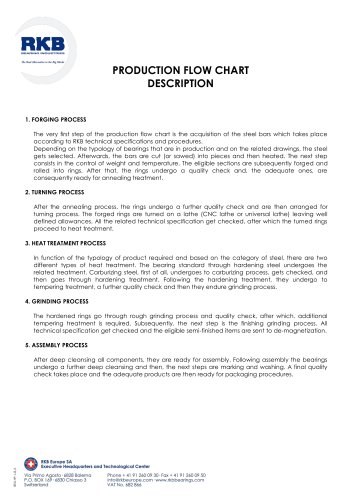

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages