Catalog excerpts

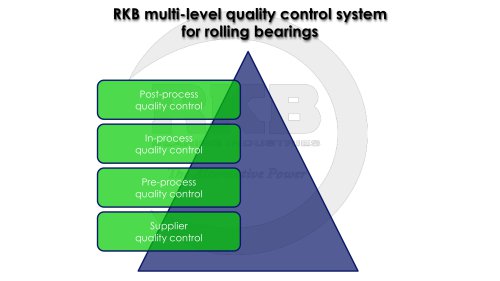

Technical Training Program The Alternative Power Via Primo Agosto· 6828 Balerna· Switzerland P.O. BOX 169· 6830 Chiasso 3· Switzerland Phone + 41 91 260 09 30· Fax + 41 91 260 09 50 info@rkbeurope.com www.rkbbearings.com VAT No. 682 866 Engineered in Switzerland Technological Bearings ON-LINE EDUCATIONAL VIDEOS RKB SPECIAL BEARING STEEL FOR PREMIUM RELIABILITY Objectives • Compare the traditional method for producing steel and the new technology (VAR-ESR) in RKB protocol • Identify the main advantages of RKB steel.RAV in terms of material properties and bearing reliability Instructor Eng. C. Radu, Ph.D. RKB Technical Team Unit RKB TOUGH ROLLER TECHNOLOGY FOR HEAVY LOAD CONDITIONS Objectives • Analyze the RKB production flow chart of a roller made of forged steel and its peculiar qualities • Determine the range of critical applications where RKB Tough Rollers can lead to better performance Instructor Eng. L. Mara RKB Application Engineer RKB SPHERICAL ROLLER BEARINGS: EXECUTIONS AND APPLICATIONS Objectives • Learn the range of available executions of RKB spherical roller bearings and their technical specifications • Understand the differences between executions in terms of manufacturing process and application suitability Instructor Eng. C. Bozan, Ph.D. RKB Advanced Software Engineering Unit RKB SOFTWARE SYSTEMS FOR BEARING CALCULATIONS Objectives • Clarify the crucial role played by bearing load ratings calculations (MTDS) • Familiarize with the parameters influencing the calculations of the basic and modified rating life of a rolling bearing (RRLC) Instructor Eng. C. Danaila, Ph.D. RKB Advanced Software Engineering Unit THE NONCONFORMITIES IN THE BEARING MANUFACTURING PROCESS AND THE ROLE OF QUALITY CONTROLS Objectives • Understand the main reasons for nonconformities during different stages of the bearing manufacturing process • Learn the importance of a multilevel quality control system to detect nonconformities and implement effective solutions Instructor Eng. C. Radu, Ph.D. RKB Technical Team Unit RKB SPECIAL HEAT TREATMENTS FOR HEAVY DUTY APPLICATIONS Objectives • Learn the best practices and technologies to conduct bainite and stabilization treatments on rolling bearings • Understand how to select the properly treated bearing steel based on the final application requirements Instructor Eng. V. Oana RKB Technical Team Unit INTERNAL EXECUTIONS OF RKB SINGLE-ROW TAPER ROLLER BEARINGS Objectives • Understand the concepts of dimensional precision class and internal geometry manufacturing precision • Explore the concepts of general interchangeability and interchangeability of bearing parts Instructor Eng. V. Manolescu RKB Application Engineer RKB ANTI-WEAR TECHNOLOGY FOR EXTENDED SERVICE LIFE Objectives • Discover the role of the chemical processes at the base of antiwear treatments • Deepen the tribology aspects of RKB surface treatments to extend bearing service life Instructor Eng. C. Radu, Ph.D. RKB Technical Team Unit Objectives • Spot the differences in execution between the AVH cage and rivet-type cage of cylindrical roller bearings • Understand the variation of behavior of the AVH cage and rivettype cage through FEM analysis Instructor Eng. C. Danaila, Ph.D. RKB Advanced Software Engineering Unit AVH CAGE AND RIVET-TYPE CAGE OF RKB CYLINDRICAL ROLLER BEARINGS Objectives • Learn the best practices for mounting and maintenance operations of multi-row bearings • Explore the main todos and not-todos to obtain longer service life from multi-row bearings Instructor Eng. L. Mara RKB Application Engineer RKB MULTI-ROW BEARINGS: MOUNTING AND MAINTENANCE OPERATIONS

Open the catalog to page 1

The RKB Group is an international manufacturing organization operating in the bearing industry with headquarters in Switzerland. The experience gained in this sector provides RKB with the know-how and expertise necessary for the development and production of technological value-added bearings, particularly in the field of heavy duty machines and equipments. All RKB bearings are manufactured in conformity with the International Standards in owned plants that are ISO 9001 and ISO 14001 certified. Thanks to its pioneer business model, based on a vertically integrated system, RKB offers...

Open the catalog to page 2All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

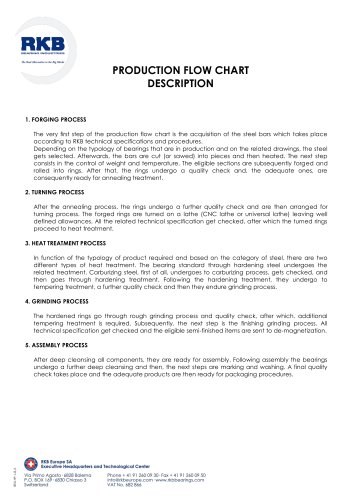

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages