Catalog excerpts

RKB spherical roller bearings: executions and applications

Open the catalog to page 1

RKB spherical roller bearings are produced with the latest technology available: • advanced calculation and simulation tools for continuous improvement of inner design and geometry • special bearing steel for premium reliability • special treatments for rings and rollers to meet application requirements • special CNC machined raceways and rollers surface finishing for proper roughness, elastohydrodynamic lubrication (EHL) and film thickness • CNC machined brass cage for uniform running and even load distribution The latest technology ensures: • precision, accuracy and long time performance...

Open the catalog to page 2

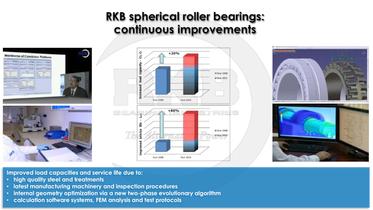

RKB spherical roller bearings: continuous improvements Improved load capacities and service life due to: • high quality steel and treatments • latest manufacturing machinery and inspection procedures • internal geometry optimization via a new two-phase evolutionary algorithm • calculation software systems, FEM analysis and test protocols +20% +80%

Open the catalog to page 3

RKB spherical roller bearings: continuous improvements RKB constantly uses the most modern technology to properly evaluate the performance of every new product. The test rig center in RKB T3 Plant was recently enlarged with the installation of the new ABLT 5A, a rapid bearing life and reliability evaluation tool that solves problems connected to accelerated automatic rolling bearing fatigue life and reliability and fast failure analysis system technology.

Open the catalog to page 4

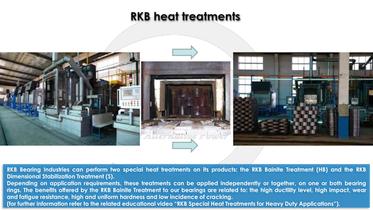

RKB heat treatments RKB Bearing Industries can perform two special heat treatments on its products: the RKB Bainite Treatment (HB) and the RKB Dimensional Stabilization Treatment (S). Depending on application requirements, these treatments can be applied independently or together, on one or both bearing rings. The benefits offered by the RKB Bainite Treatment to our bearings are related to: the high ductility level, high impact, wear and fatigue resistance, high and uniform hardness and low incidence of cracking. (for further information refer to the related educational video “RKB Special...

Open the catalog to page 5

RKB thermo-chemical treatments Thanks to these treatments, the metal-to-metal friction between the contact surfaces of the bearing components is reduced. In this way, we diminish the risk of premature bearing failure and extend bearing service life. The benefits offered by the RKB Anti-Wear Treatment to our bearings are related to: improved roughness, reduced coefficient of friction, high wear resistance, high fatigue strength, unchanged dimensions, form, hardness and metallurgical structure of the material. (for further information refer to the related educational video “RKB Anti-Wear...

Open the catalog to page 6

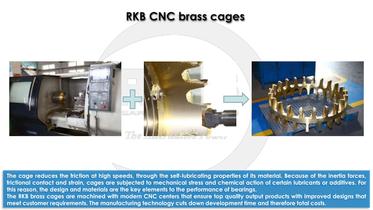

RKB CNC brass cages The cage reduces the friction at high speeds, through the self-lubricating properties of its material. Because of the inertia forces, frictional contact and strain, cages are subjected to mechanical stress and chemical action of certain lubricants or additives. For this reason, the design and materials are the key elements to the performance of bearings. The RKB brass cages are machined with modern CNC centers that ensure top quality output products with improved designs that meet customer requirements. The manufacturing technology cuts down development time and...

Open the catalog to page 7

RKB precision and performance Standard class - SRB Tighter dimensional tolerance- custom SRB The RKB dimensional, surface and form parameters are daily checked by a continuous dimensional inspection aiming at quality assurance of our finished products and manufacturing processes. RKB spherical roller bearings are also available with reduced and increased internal clearances (C2, C3, C4 and so on), with cylindrical or taper bore. Besides, there are special executions for specific applications such as wire and rod mills in the steel industry or sealed type, identified by the suffix 2CZ, for...

Open the catalog to page 8

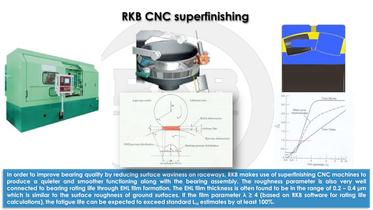

RKB CNC superfinishing In order to improve bearing quality by reducing surface waviness on raceways, RKB makes use of superfinishing CNC machines to produce a quieter and smoother functioning along with the bearing assembly. The roughness parameter is also very well connected to bearing rating life through EHL film formation. The EHL film thickness is often found to be in the range of 0.2 – 0.4 ìm which is similar to the surface roughness of ground surfaces. If the film parameter ë 4 (based on RKB software for rating life calculations), the fatigue life can be expected to exceed standard...

Open the catalog to page 9

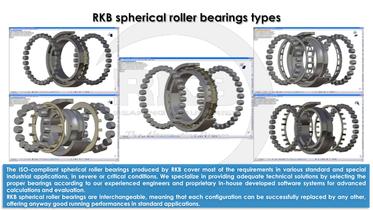

RKB spherical roller bearings types The ISO-compliant spherical roller bearings produced by RKB cover most of the requirements in various standard and special industrial applications, in severe or critical conditions. We specialize in providing adequate technical solutions by selecting the proper bearings according to our experienced engineers and proprietary in-house developed software systems for advanced calculations and evaluation. RKB spherical roller bearings are interchangeable, meaning that each configuration can be successfully replaced by any other, offering anyway good running...

Open the catalog to page 10

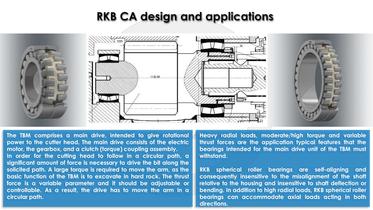

RKB CA design and applications Bearing with symmetrical rollers and retaining ribs. The cage is a one-piece, double pronged machined cage of brass

Open the catalog to page 11

RKB CA design and applications In special industrial applications (tunnel boring machines – TBM, drilling units etc.), bearings are subjected to variable working conditions with high vibrations, shock loads and contaminants. RKB CA design is conceived and manufactured to provide reliability in such conditions. CA design is used for large bore bearings, supporting high radial loads and moderate axial loads. The cage design offers improved strength to guide the heavy rollers through the accelerations and decelerations experienced when entering and exiting the loaded zone.

Open the catalog to page 12

RKB CA design and applications The TBM comprises a main drive, intended to give rotational power to the cutter head. The main drive consists of the electric motor, the gearbox, and a clutch (torque) coupling assembly. In order for the cutting head to follow in a circular path, a significant amount of force is necessary to drive the bit along the solicited path. A large torque is required to move the arm, as the basic function of the TBM is to excavate in hard rock. The thrust force is a variable parameter and it should be adjustable or controllable. As a result, the drive has to move the...

Open the catalog to page 13All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

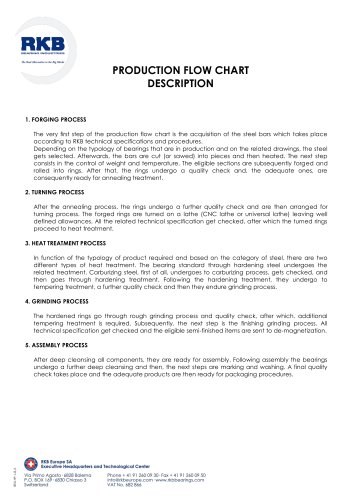

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages