Catalog excerpts

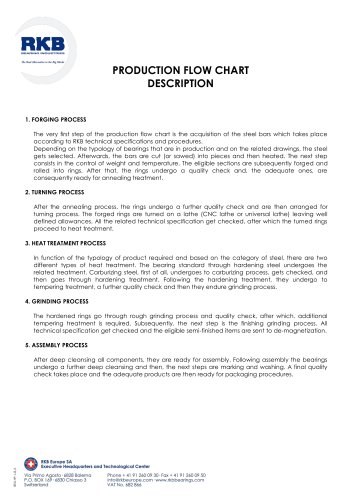

RKB ROLLERS PRODUCTION FLOW CHART DESCRIPTION 1. SELECTION PROCESS The very first step of the production flow chart for the rollers consists in the purchase of the steel bars, which takes place according to RKB technical specifications and procedures. Depending on the typology of rollers that are in production, and on the related drawings, the steel gets selected. The bars are cut or sawed into sections. Afterwards, they will proceed to a quality check aimed to identify the eligible ones for turning process. 2. TURNING PROCESS The sections are arranged for turning process whereby they get turned on a lathe (CNC lathe or universal lathe) leaving well defined allowances. All the related technical specification get checked, after which the turned rollers proceed to heat treatment. 3. HEAT TREATMENT PROCESS In function of the typology of product required and based on the category of steel, there are two different types of heat treatment. The bearing standard through hardening steel undergoes the related treatment. Carburizing steel, first of all, undergoes to carburizing process, gets checked, and then goes through hardening treatment. Following the hardening treatment, they undergo to tempering treatment, a further quality check and then they endure grinding process. 4. GRINDING PROCESS The hardened rollers go through rough grinding process and quality check. Subsequently, the next step is the finishing grinding process. All technical specification get checked and the eligible semifinished rollers are sent to demagnetization. 5. FINAL PHASE The rollers undergo the polishing process, get checked and then sorted for allocation in graded batches in function of the dimensions and of the tolerances. The rollers are now ready for matching with the bearings’ rings.

Open the catalog to page 1All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages