Catalog excerpts

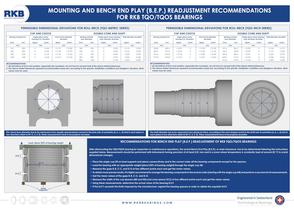

MOUNTING AND BENCH END PLAY (B.E.P.) READJUSTMENT RECOMMENDATIONS BEARING INDUSTRIES PERMISSIBLE DIMENSIONAL DEVIATIONS FOR ROLL NECK (TOO METRIC SERIES) 1. All deviations of form and position, especially the roundness, do not have to exceed half of the above stated tolerances. 2. The above stated tolerances represent recommended values but, according to the specific installation conditions and designer's decision, other PERMISSIBLE DIMENSIONAL DEVIATIONS FOR ROLL NECK (TQO INCH SERIES) 1. All deviations of form and position, especially the roundness, do not have to exceed half of the above stated tolerances. 2. The above stated tolerances represent recommended values but, according to the specific installation conditions and designer's decision, other The chock bore diameter has to be measured in four equally spaced planes normal to the bore axis of symmetry (a, b, c, d) and in each plane in four directions offset at 45° (1, 2, 3, 4). These measurements have to be properly recorded. The shaft diameter has to be measured in four planes (or three, according to the neck shape) normal to the shaft axis of symmetry (a, b, c, d) and in each plane in four directions offset at 45° (1, 2, 3, 4). These measurements have to be properly recorded. Load: about 50% of bearing weight RECOMMENDATIONS FOR BENCH END PLAY (B.E.P.) READJUSTMENT OF RKB TQO/TQOS BEARINGS After dismounting the TQO/TQOS bearing for inspection or maintenance operations, the actual Bench End Play (B.E.P.), or axial clearance, has to be determined following the instructions supplied below. Measurements should be performed with instruments having precision of at least 0.01 mm and in a room where temperature is constantly kept at around 20 °C to avoid dimensional changes. • Place the single cup DE on level supports and place consecutively and in the correct order all the bearing components except for the spacers. • Load the bearing with an appropriate weight (about 50% of bearing weight) through the single cup AB. • Measure the gaps B-B, C-C, and D-D at four different points each and get the mean values. • To obtain more precise results, it is highly recommend to arrange the bearing components in the reverse order (starting with the single cup AB) and perform a second set of measurements. • Get the mean values of the gaps B-B, C-C, and D-D. • Measure the width of the cup spacers (BB and DD) and cone spacer (CC) at four different points each and get the mean values. • Using these measurements, determine the actual value of the bearing B.E.P. • If the B.E.P. exceeds the limits imposed by the manufacturer, regrind the bearing spacers in order to obtain the requisite B.E.P. Technological Bearings

Open the catalog to page 1All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

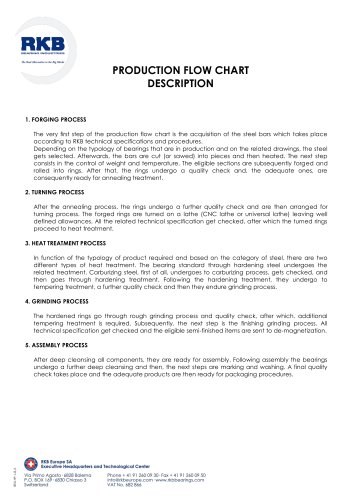

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages