Catalog excerpts

What is RKB Phosphate Treatment (PT)? RKB: the Swiss Premium-Class Bearing Manufacturer The RKB Bearing Industries Group is the Swiss manufacturing organization operating in the bearing industry for over 70 years, with a monthly production capacity exceeding 350 tons of machined steel. The experience gained over the years provides RKB with the know-how and expertise necessary for the development and manufacture of technological industrial bearings up to 1925 mm outer diameter. RKB offers reliable cost-effective solutions, with extreme operational exibility, leadingedge service, huge stock availability, short delivery time and the quality typical of a consistent premium-class bearing source. With a worldwide distribution network and exports to more than 50 countries, RKB is globally recognized as “The AlternativePower” in the bearing industry. The RKB Phosphate Treatment (PT) is a chemical conversion coating treatment in which the bearing components made of hardening steels are immersed in a dilute solution of phosphoric acid and zinc phosphate. Loss of hydrogen at the metal-solution interface results in a localized rise of pH and subsequent Grown zinc phosphate coating precipitation of the coating. During crystals of different sizes the resulting chemical reaction (acidC1 base reaction), the surfaces of bearing N1 components are chemically converted to an N2 integral oil absorptive layer of insoluble zinc phosphate crystals of about 8.0 to16 g/m2 weight or 4 μm to 8 μm thickness. The intrinsic C1 lubricating properties of the zinc phosphate O2 O3 P1 coating and its capacity to absorb a PHOSPHATE remarkable amount of lubricant favor an O2 Mn O2 easier running-in by creating a non-metallic barrier between the bearing components. This way, the RKB Phosphate Treatment (PT) O3 provides a superior resistance to friction, corrosion and wear. Engineering and Manufacturing Solutions at Your Service! • • • • • • • • Technical consultancy Application analysis and feasibility study Bearing engineering and design Advanced calculations FEM and semi-analytical simulations Project co-engineering Product customization and optimization Advanced and exible manufacturing technology • Qualied on-eld assistance RKB Europe SA Executive Headquarters and Technological Center Phone +41 91 260 09 30· Fax +41 91 260 09 50 Via Primo Agosto· 6828 Balerna info@rkbeurope.com· www.rkbbearings.com Switzerland ENGINEERED IN SWITZERLAND TECHNOLOGICAL BEARINGS

Open the catalog to page 1

RKB Phosphate Treatment - PT4 • Rolling bearings with surface treated rings and rollers (PT4) are devised for arrangements subjected to extreme operating conditions, in case of high demands on correct performance and when bearings are in contact with alkalescent-acidescent coolants. Four-ball test: friction torque vs axial load Steel/Steel Phosphate/Phosphate RKB Phosphate Treatment - PT5 • Rolling bearings with surface treated balls or rollers (PT5) are mainly suitable for applications where high speeds, light loads, unfavorable lubrication (ĸ < 1.5) and high radial or peripheral...

Open the catalog to page 2All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

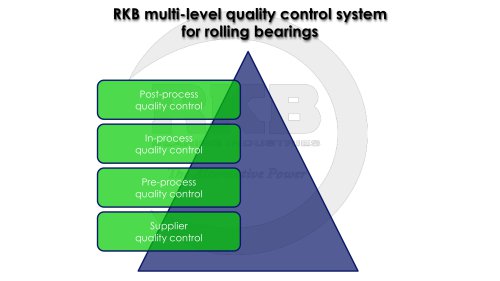

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

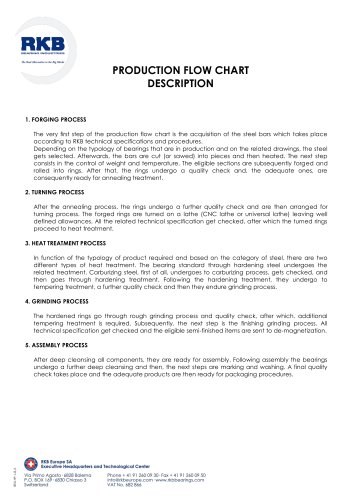

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages