Catalog excerpts

OPTIMAL DESIGN OF ROLLING-CONTACT BEARINGS VIA EVOLUTIONARY ALGORITHMS RKB TECHNICAL REVIEW - APRIL 2011 Optimal Design of Rolling-Contact Bearings Via Evolutionary Algorithms Lucian Tudose, Cristina Stanescu RKB Bearing Industries - Advanced Calculations and Optimization Department Abstract: RKB Bearing Industries Group has been using Evolutionary Algorithms for long, well aware that optimized products can make a difference in performance compared to the other producers. This paper is a brief review of the main aspects of the optimal design and a report on the achievements of the RKB Advanced Calculations and Optimization Department in the field. The differences between optimal design and conventional design are pointed out by way of a very simple example of mechanical design. Multi-objective optimal design via Evolutionary Algorithms of a specific cylindrical roller bearing is also presented. Key words: Optimization, Bearing, Evolutionary algorithms, Optimal design 1. Optimal design in modern engineering Optimization is an important concept in engineering. Finding any solution to a problem is not nearly as good as finding the one optimal solution to the problem. In the last decades the complexity of conceived products have met an extraordinary growth and it is estimated that, in the near future, designing a product will have to take into consideration a multitude of factors including actual design, manufacturing and logistics (supplying and distribution). The ever growing complexity of design problems obviously requires appropriate instruments. The present tendency in technical design of products is optimal design, which means conceiving and solving a mathematical programming problem based on the mathematical model of a real engineering problem. 2. Structure of mathematical programming problems In mathematics, optimization, or mathematical programming, refers to choosing the best element from some set of available alternatives. Often, this number of possible alternatives is infinite or, at least, very high in computational time terms. It is worth noting here that the term mathematical programming is not directly related to computer programming. A mathematical programming problem has to fit to a certain format. Let the decision (design) variable vector be: x x1, x 2 , ... , x p and suppose that its components are laying in the ranges: l l u l u x1 x1, x1 , x 2 x 2 , x 2 , ... , x p x p , x u p Consider also the objective function (mono-objective optimization) or objective functions (multi-objective optimization) and a set of constraints (all of these are functions of the decision vector x ). Note that mono-objective optimization and multi-objective optimization respectively are two totally different approaches as will be seen in the following pages. To solve this mathematical programming problem means that one has to find x so that: f1 x min or max f x min or max objective function(s): 2 fm x min or max 1

Open the catalog to page 1

OPTIMAL DESIGN OF ROLLING-CONTACT BEARINGS VIA EVOLUTIONARY ALGORITHMS RKB TECHNICAL REVIEW - APRIL 2011 g1 x 0 g 2 x 0 constraints: g q x 0 where the sign “ ” should be read “less than” or “less than or equal to” or even “equal to” as appropriate. 3. Optimal design versus conventional design To fully understand the fundamental differences between conventional and optimal design will address a simple statement of the design of machine parts. The main problem in the field of mechanical design work is the dimensioning (sizing) of machine parts according to some known requirements. Sometimes...

Open the catalog to page 2

OPTIMAL DESIGN OF ROLLING-CONTACT BEARINGS VIA EVOLUTIONARY ALGORITHMS RKB TECHNICAL REVIEW - APRIL 2011 Let's illustrate the above considerations by approaching a very simple design problem: the tubular beam of length L in figure 1 is centrally loaded by force F. Knowing the material of the beam, the problem is to find the values of outer diameter Do and inner diameter Di of the beam. The only equation available for dimensioning is the well-known bending stress equation: σb 16 F L Do 4 π Do Di4 Since there are two unknowns (Do and Di) and only one equation, in conventional design, one of...

Open the catalog to page 3

OPTIMAL DESIGN OF ROLLING-CONTACT BEARINGS VIA EVOLUTIONARY ALGORITHMS RKB TECHNICAL REVIEW - APRIL 2011 used. A typical case would be that when one wants high performance, while aiming to reduce, as much as possible, the costs. Objective functions can be the mass of single parts or subassemblies, radial or axial basic dynamic load rating of bearings, minimum thickness of the elastohydrodynamic lubricant film between the rolling element and bearing raceway, deformations of components of construction, potential energy stored, efficiency of transmission etc. A very important step in building...

Open the catalog to page 4

OPTIMAL DESIGN OF ROLLING-CONTACT BEARINGS VIA EVOLUTIONARY ALGORITHMS RKB TECHNICAL REVIEW - APRIL 2011 Fig. 2 - Bi-objective Pareto front 6. What are Evolutionary Algorithms? If one goes for the optimal design option, the next step is to select the instrument for solving the mathematical programming problem. Most traditional techniques for the optimization of systems of several parameters involve the calculation of the first and second order partial derivatives of the objective function with respect to all variables. However, the situations where the analytical approach is difficult...

Open the catalog to page 5

OPTIMAL DESIGN OF ROLLING-CONTACT BEARINGS VIA EVOLUTIONARY ALGORITHMS RKB TECHNICAL REVIEW - APRIL 2011 Fig. 3 - Principle of a very simple Evolutionary Algorithm Since the simplest EAs are good at exploring the solution space (because they search from a set of designs and not from a single design solution), their important drawback is that they are not well suited to perform finely tuned search. Starting from an idea of P. Moscato (1989) it has been argued (Hart, 1994; Wolpert, 1997; Culberson, 1998; Goldberg 1999) that it is essential to incorporate some form of domain knowledge into EAs...

Open the catalog to page 6All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

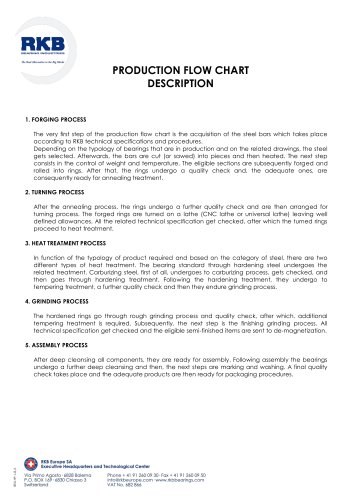

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages