Catalog excerpts

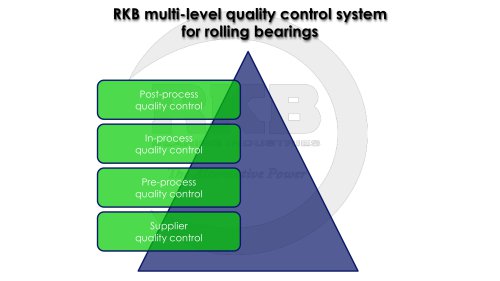

RKB multi-level quality control system for rolling bearings Post-process quality control In-process quality control Pre-process quality control Supplier quality control

Open the catalog to page 1

Material Guidelines JX80X Series Supplier Quality Assurance Agreement (SQAA) Quality Control Bureau (QCB) QCB departments PACD laboratories Released documents Advanced Measurements Laboratory (AML) Masterpiece Quality Certificate (MQC) Product Approval Control Department (PACD) Metallographic Quality Control Laboratory (MQCL) Measuring Instruments Approval Certificate (MIAC) Forging Operational Plans (FOP) Bearing Lot Quality Approval (BLQA) Quality Technical Service (QTS) Mechanical Testing Laboratory (MTL) Raw Material Quality Final Report (RMQFR) Heat Treatments Operational Plans (HTOP)...

Open the catalog to page 2

RKB supplier quality control Supplier Quality Assurance Agreement (SQAA) Raw material supplier identification RKB Material Guidelines JX80X Series adoption Valid accomplishment plan and requirements fulfillment NO YES Favorable periodic audit results YES Raw material metallographic multi-test inspections YES PACD/MQCL approval and issue of Raw Material Quality Control Final Report Approved supplier Rejected supplier

Open the catalog to page 3

•Trace element analysis (ISO 683-17:1999) Chemical composition analysis Macro-structure inspection Micro-structure inspection Mechanical properties determination •Blue fracture test (assessment of non-metallic macroinclusion content, ISO 3763:1976) •Macro-etching method (evaluation of porosity, segregation and other material defects ASTM E 340-00:2006) •Micro-etching method (assessment of non-metallic inclusion content, carbide size, carbide networks, carbide streaks and carbide segregation rate, ISO 4967:1998 (E) and ISO 5949:1983) •Brinell hardness test (ISO 6506-1:2005) •Rolling contact...

Open the catalog to page 4

Rough, fine grinding and polishing machine Metallographic microscopes RKB Metallographic Quality Control Laboratory Chemical reagents Spectrometer analyzer

Open the catalog to page 5

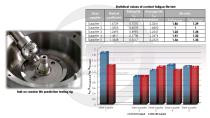

Statistical values of contact fatigue life test Steel supplier Weibull coefficient Supplier 1 Supplier 2 Supplier 3 Supplier 4 Supplier 5 Ball-on-washer life prediction testing rig Steel supplier Steel supplier Steel supplier Steel supplier 2 3 4 5 L10/L10 supp2 L50/L50 supp2

Open the catalog to page 6

RKB pre-process quality control RKB rolling bearing rings masterpieces production RKB rolling bearing rollers masterpieces production

Open the catalog to page 7

CNC lathe machine for rings masterpieces turning operation CNC grinding machine for rollers masterpieces fine grinding operation CNC grinding machine for rings masterpieces fine grinding operation CNC machine for rollers masterpieces superfinishing operation

Open the catalog to page 8

24032CAC4STHB1W33S1VL inner ring, outer ring and roller masterpieces for turning, rough grinding and fine grinding operations High precision measurements of 24032CAC4STHB1W33S1VL inner ring masterpiece for fine grinding operation using COORD 3 coordinate measuring machine

Open the catalog to page 9

RKB rolling bearing rings production RKB rolling bearing rollers production

Open the catalog to page 10

Forging quality parameters •Steel properties •Dimensions (e.g. bar diameter and length) •Weight Operation parameters •Heating temperature Pre-operation parameters Heating temperature control using a pyrometer •Dimensional parameters (diameters, width, length) Product parameters Forged ring width measuring using an analog vernier caliper Forged ring bore diameter measuring with an analog vernier caliper Forged bulk material measuring using an analog external caliper

Open the catalog to page 11

Heat treatment quality parameters •Steel properties •Furnace atmosphere •Heating time •Heating temperature •Quenching time •Form accuracy Hardening temperature control Microstructure inspection using a pyrometer using a metallographic microscope Rockwell C hardness measuring Form accuracy parameter measuring with an electronic hardness meter using an analog comparator gauge

Open the catalog to page 12

Machining quality parameters •Cutting speed •Feeding rate •Stone granulation •Dimensional parameters •Geometrical parameters Parallelism control using an Raceway curvature control Flange width measuring with an analog comparator gauge using a geometrical pattern analog vernier caliper Flange inner face angle measuring Bore taper ang|e control Bearing total height measuring with an analog angle gauge wjfn two analog vernier calipers using an analog vernier caliper

Open the catalog to page 13

Magnetic Particle Inspection (MPI) of rollers Magnetic Particle Inspection (MPI) of bearing rings Ultrasonic Micro-Crack Detection (UMCD) test of bearing rings

Open the catalog to page 14

RKB post-process quality control Visual inspection Dimensional and geometrical control Surface quality control Packaging conditions Radial and/or axial internal clearance (DIN 620-4:2004) Waviness and roughness of inner ring bore and raceway surface Bearing identification code Bearing boundary dimension deviations and geometrical parameters (ISO 492:2002, ISO 355:2007, ISO 104:2002) Waviness and roughness of outer ring outer surface and raceway surface Dimension deviations and geometrical parameters of inner rings, outer rings, rollers and cages (ISO 492:2002, ISO 355:2007, ISO 104:2002)...

Open the catalog to page 15

COORD 3 coordinate measuring machine Form Talysurf Intra

Open the catalog to page 16

Neophot 2 metallographic microscope Handy Esatest digital hardness tester

Open the catalog to page 17

QI'ALIIV CERTIFICATE OF CONFORMITY DATA SHEET INSPECTION CERTIFICATE DATA SHEET Bcari»c Spccificatm: Beomg Specification: ired acUal value Bore SpociteoHon Bore Actual T♦*c^n*c.al J«Kyri Unit

Open the catalog to page 18

• The best improved bearing steel • Latest knowledge of micro-geometry and surface topography • Improved manufacturing technology (high precision machining and special heat treatments) • Advanced software engineering • Advanced material engineering • Special heat treatments (bainite treatment - HB and anti-wear treatment - AWT) • High precision machining • Bainite treatment and dimensional stabilization for rings (HB+S1) • Outer ring guided cage MA design with special open-end design • Controlled radial clearance in restricted range • Precision class higher than standard for 223 series •...

Open the catalog to page 19All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages