Catalog excerpts

GENERAL QUALITY PROGRAM

Open the catalog to page 1

General Quality Program © 2011 The contents of this document are copyright of the publisher Every care has been taken to ensure the accuracy of the information in the present document but no liability can be accepted for any errors and/or omissions contained herein, or in case losses and/or damages (direct, indirect, consequential) should occur. RKB reserves the right to change, modify or update its procedures and specifications without any prior notice.

Open the catalog to page 3

Heat treatments Dimensional features Controls and final tests General quality policy Appendix: production flowcharts Masterpieces Rings Rollers Balls Cages Thermo-chemical treatments Assembly Multilevel quality controls

Open the catalog to page 5

Materials RKB makes use of SAE 52100 steel to manufacture rolling bearings for common applications. Under certain circumstances and most of all for medium and large size bearings, SAE 52100/A is adopted. Regarding critical applications, a special bearing steel (SAE A485 or RKB Type.RAV), with higher cleanliness and specific mechanical properties, is used. This steel, obtained through the Vacuum Degassed Electroslag Remelting process (VAC-ESR), has lower levels of non-metallic inclusions and ensures premium product reliability and performance. As for the manufacture of rollers, the RKB Group...

Open the catalog to page 7

Heat treatments All RKB bearing steels are hardened and heat treated to obtain optimum mechanical properties. In addition to the conventional thermal cycles, RKB can perform two special heat treatments on its products: RKB Bainite Treatment (HB) for decreasing ring crack incidence and RKB Dimensional Stabilization Treatment (S) for ring dimensional stability up to an operating temperature of 350 °C. Finally, two thermochemical surface treatments are available: RKB Anti-Wear Treatment (AWT), essential to reduce the metal‑on‑metal friction between contact surfaces, and RKB Phosphate Treatment...

Open the catalog to page 8

Dimensional features As for dimensional accuracy, generally a batch of tests and in-line controls is carried out. First of all, each machine is predisposed to the RKB production method. Afterwards components are tested by the RKB QC (Quality Control) Staff. The operator is expected to make the choice personally, where possible, and, with the help of the QC Staff, to verify that these choices are properly made at regular breaks during production. At the end of every turning cycle and grinding cycle, a security control system is launched and a check for compliance with the close tolerances of...

Open the catalog to page 9

Controls and final tests Visual checks on all surfaces of manufactured products, finished and ready for assembly, are regularly carried out to avoid any visually noticeable anomaly. Selection of rolling elements in groups with defined grade and raceway values measurement of internal and external rings for the correct matching with radial clearance determined on the production order are made by the RKB Assembling Department. Specific controls with related tables and charts, including possible residual magnetism limits and non-destructive controls with MPI (Magnetic Particle Inspection) and...

Open the catalog to page 10

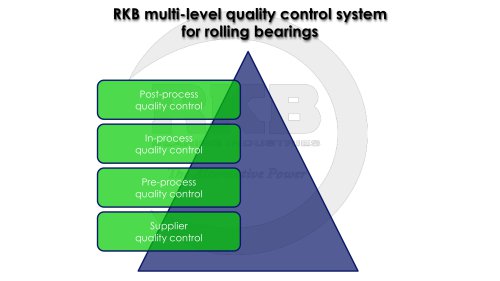

General quality policy All the systems, procedures, programs and protocols followed by the RKB Group are in conformity with ISO 9001 and ISO 14001. These systems are based on the total quality concept having as guidelines the principles of Total Quality System (TQS), Company Wide Quality Control (CWQC) and Quick Response Manufacturing (QRM), at all levels of research, development, engineering, manufacturing, control, traceability and repeatability. These systems are executed on the basis of regular plans and corrective feedbacks are implemented in the event of any negative variance with the...

Open the catalog to page 11

BEARING INDUSTRIES PRODUCTION FLOWCHARTS

Open the catalog to page 13

RKB rolling bearing rings masterpieces production flowchart

Open the catalog to page 15

RKB rolling bearing rollers masterpieces production flowchart

Open the catalog to page 16

RKB rolling bearing rings production flowchart

Open the catalog to page 17

RKB rolling bearing rings steel bar cutting flowchart

Open the catalog to page 18

RKB small and medium size rolling bearing rings hot forging flowchart

Open the catalog to page 19

RKB large size rolling bearing rings hot forging flowchart

Open the catalog to page 20

RKB rolling bearing rings annealing treatment flowchart

Open the catalog to page 21

RKB rolling bearing inner/outer rings turning flowchart

Open the catalog to page 22

RKB rolling bearing rings carburizing, quench hardening and tempering flowchart

Open the catalog to page 23

RKB rolling bearing rings bainite and dimensional stabilizing treatment flowchart

Open the catalog to page 24

RKB cylindrical roller bearing inner rings rough grinding flowchart

Open the catalog to page 25

RKB cylindrical roller bearing outer rings rough grinding flowchart

Open the catalog to page 26

RKB rolling bearing rings additional tempering treatment flowchart

Open the catalog to page 27

RKB cylindrical roller bearing inner rings fine grinding and finishing flowchart

Open the catalog to page 28

RKB cylindrical roller bearing outer rings rough grinding flowchart Flonge inner surface fine grinding/ Flange inner face fine grinding/

Open the catalog to page 29

RKB rolling bearing rollers production flowchart

Open the catalog to page 30

RKB rolling bearing rollers turning flowchart Tough (forged) standard Turning type Double roller Roller ldchcmfer Roller raceway

Open the catalog to page 31

RKB rolling bearing rollers

Open the catalog to page 32

RKB rolling bearing rollers annealing treatment flowchart

Open the catalog to page 33

RKB rolling bearing rollers carburizing and/or quench hardening and tempering flowchart tempering temperature

Open the catalog to page 34

RKB rolling bearing rollers rough grinding flowchart Carburizing and/or quench

Open the catalog to page 35

RKB rolling bearing rollers fine grinding flowchart

Open the catalog to page 36

RKB rolling bearing rollers finishing flowchart

Open the catalog to page 37

RKB rolling bearing rollers final quality control flowchart

Open the catalog to page 38

RKB rolling bearing steel balls production flowchart

Open the catalog to page 39

RKB rolling bearing machined brass cage production flowchart

Open the catalog to page 40

RKB rolling bearing pressed steel cages production flowchart

Open the catalog to page 41

RKB rolling bearing rings and rollers/balls anti-wear treatment flowchart

Open the catalog to page 42

RKB rolling bearing ring, roller and cage zinc phosphating flowchart Bearing component Deep cleaning phosphate solution Cold water cleaning Forced drying

Open the catalog to page 43

assembly flowchart cage assembling with rivets. Machine screw retaining ring Vacuumed plastic foil pocking Wooden cose collective packing Protective plastic foil Protective paper Protective band Wooden case collective packing Protective plastic foil Protective paper Protective band Protective strip Wooden case single

Open the catalog to page 44All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages