Catalog excerpts

26 Power Transmission World - november 2011 FEATURE FOCUS Alberto Barili* The RKB Group, the Swiss premium-class bearing manufacturer, is daily committed to conceiving and developing leading-edge solutions for the wind energy industry. This implies important investments in innovation and research, with particular attention to design optimization, heat and thermochemical treatments, and manufacturing technology as a whole. Developments in wind turbine rolling bearings The sources of renewable energy are also called sources of alternative energy as the energy produced in this way is the main alternative for energy resulting from exhaustible sources. In the economy of this century, renewable energies are holding a prominent position. In particular, the wind energy has recently experienced remarkable spreading, in virtue of its inexhaustibleness and cleanliness. Of course wind energy plants may also have undesirable effects such as noise, occupancy of large areas of open space and visual impact on landscape. However, the positive aspects of this type of application (e.g. the non-introduction of several million tons of pollutants and greenhouse gases into Earth’s atmosphere) widely compensate for all possible drawbacks. Over the last years almost all wind industry manufacturers have been focusing on producing innovative design turbines able to operate even at low wind speeds (3 m/s) and generand developed specific software tools (MTDS, RRLC, NON-HERTZ etc.) to determine and study bearing most crucial parameters, such as rating life, force and stress distribution, misalignments, recommended fits and lubrication, Hertzian and non-Hertzian loads and so on. These PC programs are extremely useful when designing the complex applications of the wind energy sector since they make possible to properly and simultaneously consider all the factors affecting the behavior of the bearings mounted in the assembly. Naturally, all calculations are performed according the most advanced and recent international standards. As is evident, the service life of a wind turbine depends also on the life of the bearings that have been installed. For this reason the operation of wind turbine bearings should be efficient and reliable even under unfavorable environmental conditions. The life of a wind turbine is normally guaranteed for almost twenty years. However, a general inspection procedure is advisable every four years in order to assess the conditions of gears ate more and more power. The unceasing advancements of blades, nacelles and speed multiplicators have allowed to collect wind energy at higher and higher altitudes, also thanks to the improved capacity of the tower to support the weight of the entire system. “The Alternative Power” In an increasingly competitive sector, the RKB Group, with Executive Headquarters and Technological Center in Balerna (Switzerland), has decided heavy investments in Research & Development to efficiently satisfy the requirements of the alternative energy industry, which is becoming more and more demanding in terms of performance and cost-effectiveness. In order to optimize wind energy applications, RKB engineers rely on Catia software system to create the 3D models of the assembly and on Ansys Workbench Platform to evaluate the behavior of the bearing by means of the FEM (Finite Element Method) analysis. Besides, the RKB Group has purposely designed A ‚«

Open the catalog to page 1

november 2011 - Power Transmission World 27 3D model of a wind turbine speed multiplicator where RKB bearings are mounted. © ALL RIGHTS RESERVED œ and bearings and to replace worn parts. In addition, in order to reduce total weight and have a less costly maintenance, rolling bearings of the RN type, having the planet wheel body in place of the outer ring, are often used on the planet wheels of planetary units. This way, when it becomes necessary to grind the rolling races in the planet wheel body, the side clearance, with respect to the bearing assembly, will be higher than expected for the...

Open the catalog to page 2All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

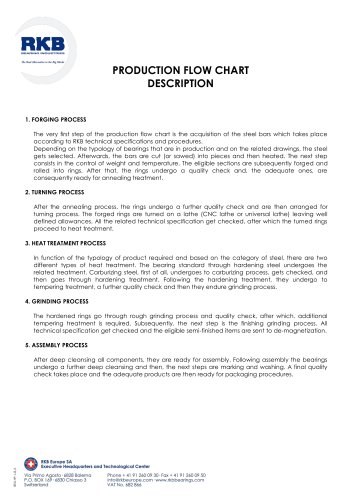

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages