Catalog excerpts

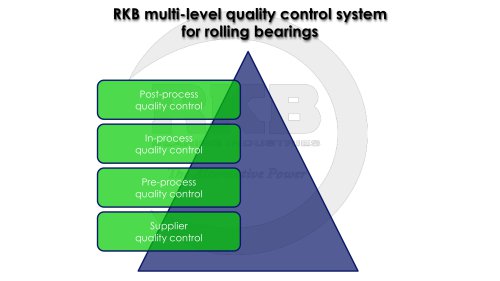

2 As you know, rolling bearings are critical components for the mechanical industry. In this specific sector, the possibility to choose products that comply with the strictest international standards, offering reliability and high quality, is a strategic factor for longterm decisions. For this reason, in the rolling bearing market, especially for large bearings, big spenders tend to resort to the oligarchy of industry giants rather than a myriad of small and unknown companies emerged in the past few decades. After all, the process to define the quality of a bearing, mainly a high-tech product built to specific application requirements, can be very long and expensive in terms of resources. In recent years, we have also seen the rise of companies that, though having no production factory, address the market as if they were actually bearing manufacturers. These are mostly organizations that assemble different components acquired from emerging markets, with no control on the supply chain and inevitable consequences on final product quality. Obviously, this misleading and fraudulent presentation of a business that does not exist generates strong mistrust in the industry as a whole. Based on this premise, knowledge and experience acquired in the field over more than seventy years have allowed the RKB Group, the Swiss manufacturer of high value added bearings, to define the features that help you tell a reliable rolling bearing supplier from an inconsistent source. This is particularly true for large bearings (mainly heavyduty products starting from 200 mm bore diameter); for these components, theory, technical competence, production technology, procedures and processes are much more complicated than for small and more popular bearings. The compliance procedure for bearing suppliers has been conceived, studied and implemented by RKB in close collaboration with the Department of industrial system technology and management of a major university in Northern Italy. For an accurate evaluation of the actual reliability and consistency of a rolling bearing supplier, from design to manufacturing up to after sales, The RKB Group recommends Purchase Departments to stick to the nine points listed hereafter: 1. If required by the situation, it is necessary to subscribe a preliminary non-disclosure agreement to protect both parties from the improper use of information transferred during the relationship; 2. The commercial evaluation shall consider general supply conditions, delivery terms and prices; 3. The technical evaluation shall be very exhaustive and the supplier must provide: application analysis, including feasibility criteria; project development; selection of bearing type and size; calculation of load capacities for veri- PubliTec Points of view A detailed to choose A numerical control vertical grinder at the RKB T3 Plant production site. by Stefano Cugno Visit the company Web site through your smartphone. How can you tell a reliable supplier of rolling bearing from an inconsistent source? The RKB Group has developed a specific procedure, studied and implemented in close collaboration with the Department of industrial system technology and management of a major university in Northern Italy. Let’s find out more. fication purposes; engineering and technical drawing of bearings; fine-tuning and optimization; declaration of technical specifications, protocols and standards adopted; advanced calculation and simulation by means of software products complying with international standards and recognized by the scientific community; traceability of all activities; 4. Evaluation of the supplier’s reputation or standing in terms of general information, qualifications, activities and liabilities, economic and financial status, expenditure and investment capacity; 5. Evaluation of the warranties offered by the supplier (Representations & Warranties), i.e. the set of certificates, affidavit, written declarations, public documents and references that formally witness to the supplier's consistency; 6. Evaluation of the supply and production chain operations, mainly as it refers to vertical integration levels, i.e. operations actually executed inside the company, and the possibility to carry out audits in the factories and headquarters to check the compliance of processes, facilities and procedures to the requested features; 7. Evaluation of laboratory analysis on the bearing, in terms of design accuracy, execution and geometry, as well as raw material quality; 8. Evaluation of tests carried out on the application and related certifications; 9. Final approval, stating that the product complies with all reference standards and project specifications. Following this procedure is essential to ensure high quality standards and a correct relationship with customers. As a matter of fact, if you define the responsibility of each actor in the bearing supply process, especially high-tech products, the procedure can guarantee that: • products comply with applicable international standards and/or with technical project documentation; • the expected bearing characteristics, parameters and performance are complied with; • relationships between the parties involved in the supply process are carried on clearly and openly, with no misleading or fraudulent behaviors, especially as relates to the consistency and reliability of companies and products. Finally, to streamline the evaluation process of the actual nature and consistency of rolling bearing suppliers, RKB has implemented the roadmap described above in a simple form (Bearing Supplier Eligibility Compliance Procedure Form) that can be downloaded from the Web (http:// www.rkbbearings.com/docs/ Bearing_Supplier_ Eligibili ty_ Compliance_Procedure_ Form.pdf) and filled out in digital. Stefano Cugno is Strategist and Market Analyst of the RKB Bearing Industries Group. T R A S M E C P u b l i T e c s r l - V i a P a s s o P o r d o i 1 0 - 2 0 1 3 9 M i l a n o - w w w . p u b l i t e c o n l i n e . i t 3 Punti di vista guide the right supplier Quality control at the RKB headquarters in Balerna (Switzerland).

Open the catalog to page 1All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

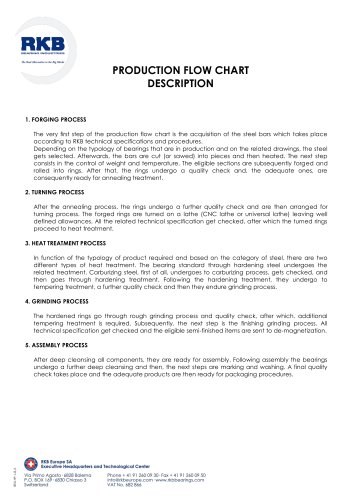

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages