Catalog excerpts

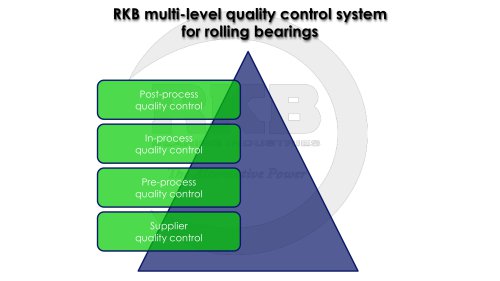

MADE IN RKB IN-HOUSE OPERATIONS Swiss made according to the legal interpretation of the main cost centre. Of non-preferential origin (N.P.O.) for customs purposes, since most operations are performed in Switzerland, while the last substantial transformation (precision fi ne-grinding) is performed in RKB T3, LN or MS Plant. This document forms an integral and substantive part of RKB’s International Producer Certifi cate. Overhaulings • Matching/pairing • Clearance reworking and adjustment • Regreasing • Reassembly in new confi guration Input • Capital and fi nance • Guidelines • Instructions • Specifi cations Technical Team Unit • Application analysis and evaluation • Product concept • Product and project development • Bearing selection • Calculations and simulations • Engineering and design • Optimization • Fine-tuning • Co-engineering • Mounting and after-sales service R&D • Materials • Treatments • Designs and executions • Precision • Contacts and profi les • Test rigs (benchmark, endurance test, validation) • Investments exceeding Euro 2 million per year Multilevel Quality Controls • Telesina Special Quality Unit (TSQU) • Steel inspection and approval of lots • In-process inspections and controls • Chemical laboratories • Metrological laboratories • Tests and measurements Production • Masterplan • Equipment at Planning • Plants • Internal • External Machining • European legal representatives • European management • Masterpieces • Parts and spare parts for • Forming/forging • Turning • Heat treatments • Grinding • Precision fi ne-grinding • Assembling • Additional operations Steel • Raw material global contract Protocols • Internal • External • Digital traceability Engineered Technological

Open the catalog to page 1All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

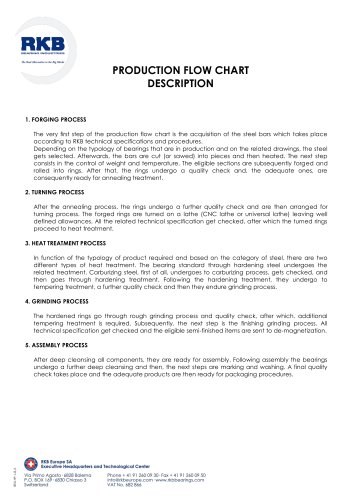

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages