It’s All About the Steel: the Importance of Bearing Steel Cleanliness for Long-Life Applications

7Pages

Catalog excerpts

IT’S ALL ABOUT THE STEEL: THE IMPORTANCE OF BEARING STEEL CLEANLINESS FOR LONG-LIFE APPLICATIONS RKB TECHNICAL REVIEW - MARCH 2011 1 It’s All About the Steel: the Importance of Bearing Steel Cleanliness for Long-Life Applications Ciprian Radu RKB Bearing Industries - Advanced Software Engineering Unit Abstract: In today’s rolling bearing industry, the demand for more and more reliable and effective products is continuous. For standard operating conditions the rating lives of bearings, with ideal internal geometries and correct mounting, are ultimately established by the quality of the steels used in the manufacturing process. For this reason, the RKB Group has undertaken extensive researches and has made great strides in the field of bearing materials and heat treatments. Our long-standing cooperation with the top-class steel manufacturers has given RKB Bearing Industries a unique understanding of material development for rolling bearings. The present paper presents an overview of the importance of the proper selection of the bearing steel for manufacturing high quality rolling bearings, according to the highest international standards. In addition, the complex interrelation between steel cleanliness and adequate heat and thermo-chemical treatments applied to bearing components is pointed out. The equilibrium between these factors has led to an increased fatigue life of the rolling bearings manufactured by RKB. Key words: Bearing steel, cleanliness, fatigue life, heat treatment, metallography, nonmetallic inclusions 1. Introduction Rolling bearings are one of the most frequent machine elements and play a key role in the reliability of the majority of industrial equipment. In this respect, the selection of the proper bearing material and its processing are of the utmost importance. Over the years, the specific requirements of rolling bearings, i.e. rolling contact fatigue strength, resistance to contact deformation and wear, toughness, machinability and hardenability, conducted to a special grade steel commonly known as bearing steel [1]. There are two major rolling bearing steel variants [2]: - the through-hardened steels (table 1), for which, after the final heat treatment, the hardness attains the high value of 58-64 HRC in the entire volume of the bearing component; - the case-hardened steels (table 2), for which a carburizing treatment increases the carbon content up to 0.65-1.10% only in a superficial layer of 15-25 mm thickness, where a proper hardening and tempering treatment ensures the needed high hardness of 58-64 HRC, while maintains the rest of the material at a much lower hardness of 25-48 HRC that provides a better operating toughness. Table 1 - The most common through-hardened bearing steels and major chemical elements composition [1; 3] Steel grade Chemical composition (%) C Mn Si Cr Mo ASTM-A295 (52100) 0.98-1.10 0.25-0.45 0.15-0.35 1.30-1.60 0.10 ASTM-A295 (50100) 0.98-1.10 0.25-0.45 0.15-0.35 0.40-0.60 0.10 ASTM-A295 (5195) 0.90-1.03 0.75-1.00 0.15-0.35 0.70-0.90 0.10 ASTM-A295 (1570) 0.65-0.75 0.80-1.10 0.15-0.35 - 0.10 ASTM-A295 (1560) 0.56-0.64 0.75-1.00 0.15-0.35 0.70-0.90 0.10 ASTM-A485 grade 1 0.95-1.05 0.95-1.25 0.45-0.75 0.90-1.20 0.10 ASTM-A485 grade 2 0.85-1.00 1.40-1.70 0.50-0.80 1.40-1.80 0.10 ASTM-A485 grade 3 0.95-1.10 0.65-0.90 0.15-0.35 1.10-1.50 0.20-0.30 ASTM-A485 grade 4 0.95-1.10 1.05 – 1.35 0.15-0.35 1.10-1.50 0.45-0.60 DIN 100CrMo6 0.92-1.02 0.25-0.40 0.25-0.40 1.65-1.95 0.30-0.40 JIS G4805 SUJ1 0.95-1.10 0.50 0.15-0.35 0.90-1.20 - JIS G4805 SUJ2 0.95-1.10 0.50 0.15-0.35 1.30-1.60 - Ovako803Q 0.90-1.00 0.20-0.40 0.15-0.40 1.40-1.60 0.10

Open the catalog to page 1

IT’S ALL ABOUT THE STEEL: THE IMPORTANCE OF BEARING STEEL CLEANLINESS FOR LONG-LIFE APPLICATIONS RKB TECHNICAL REVIEW - MARCH 2011 2 Table 2 - The most common carburizing bearing steels and major chemical elements composition [1] Steel grade Chemical composition (%) C Mn Ni Cr Mo SAE 4118 0.18-0.23 0.70-0.90 - 0.40-0.60 0.08-0.15 SAE 8620 0.18-0.23 0.70-0.90 0.40-0.70 0.40-0.60 0.15-0.25 SAE 5120 0.17-0.22 0.70-0.90 - 0.70-0.90 - SAE 4720 0.17-0.22 0.50-0.70 0.90-1.20 0.35-0.55 0.15-0.25 SAE 4620 0.17-0.22 0.45-0.65 1.65-2.00 - 0.20-0.30 SAE 9315 0.13-0.18 0.45-0.65 3.00-3.50 1.00-1.40...

Open the catalog to page 2

IT’S ALL ABOUT THE STEEL: THE IMPORTANCE OF BEARING STEEL CLEANLINESS FOR LONG-LIFE APPLICATIONS RKB TECHNICAL REVIEW - MARCH 2011 3 To find out material defects before the manufacturing process starts, steel bars are randomly subjected to nondestructive tests, the ultrasonic method being the most used. The latest achievement of the RKB Group and its steel supplier in this field is represented by a new and improved version of through-hardened steel called RKB Type.RAV Protocol, which has a chemical composition similar to SAE A485 steel. This innovative protocol is particularly suitable for...

Open the catalog to page 3

IT’S ALL ABOUT THE STEEL: THE IMPORTANCE OF BEARING STEEL CLEANLINESS FOR LONG-LIFE APPLICATIONS RKB TECHNICAL REVIEW - MARCH 2011 4 a) b) Fig. 6 - Eutectic carbide network microphotography (100x): a) SAE 52100 standard bearing steel; b) RKB Type.RAV bearing steel The high corrosion resistance of the RKB Type.RAV steel was proved in a sodium chloride solution immersion test (figure 5). As it can be easily noticed, there is excessive rust on the SAE 52100 standard bearing steel surface compared with the RKB Type.RAV steel sample. In fact, standard bearing steel contains coarse eutectic...

Open the catalog to page 4

IT’S ALL ABOUT THE STEEL: THE IMPORTANCE OF BEARING STEEL CLEANLINESS FOR LONG-LIFE APPLICATIONS RKB TECHNICAL REVIEW - MARCH 2011 5 standard bearings must be replaced quite frequently and the downtimes of entire systems, including the cost system, are to be reduced. As Comparing the investment and capital costs for RKB bearings and standard bearings, our costs are a little bit higher (figure 9). However, these costs are quite soon recovered in terms of operating and maintenance costs. Therefore, thanks to the reliability of our bearings, ensured by the cleanliness and manufacturing quality...

Open the catalog to page 5All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

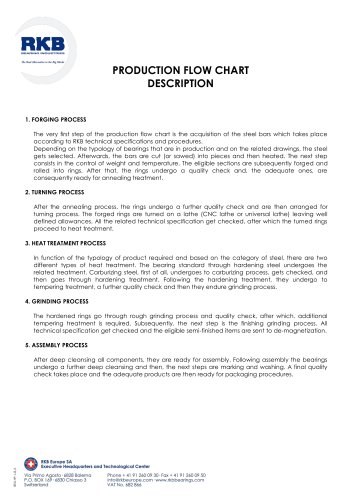

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages