Catalog excerpts

BEARING INDUSTRIES HANDLING PROCEDURE FOR CORRECT MOUNTING Bearing design In order to accommodate higher values of misalignment, in RKB spherical roller bearings WOR configuration the outer ring is redesigned and optimized in order to have an increased outer ring width. In addition, some series of WOR bearings feature two separate outer raceways connected with a clamping ring that facilitates mounting and dismounting. Integral outer ring Outer ring in two halves Mounting procedure Before starting the assembling operation, check if the outer diameter of the clamping ring is smaller than the outer diameter of the outer rings. If such a condition is verified, the bearing can be assembled directly on the shaft/housing as a normal design, without removing the clamping ring. On the contrary, if the outer diameter of the clamping ring is larger than the outer diameter of the outer rings, please remove the clamping ring prior to assembling in order to avoid damaging it (see picture 1 Executive Headquarters and Technological Center P.O. Box 169 ■ 6830 Chiasso 3 info@rkbeurope.com - www.rkbbearings.com TECHNOLOGICAL BEARINGS

Open the catalog to page 1

In this latter case, the correct sequence to mount the bearing is shown below: i) Remove the clamping ring; ii) Separate the two outer rings; iii) Insert first outer ring in the housing; iv) Insert the inner assembly (inner ring, cage and rollers), already preassembled on the shaft, into the first outer ring (see point above); v) Insert the second outer ring; vi) Bring outer rings into contact and make sure they are correctly abutting each other and are duly blocked in order to get a monolithic outer ring. For any additional information you may require, do not hesitate to contact RKB...

Open the catalog to page 2All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

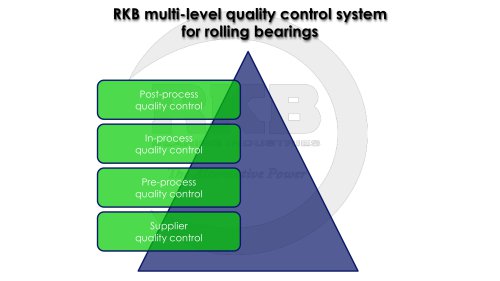

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

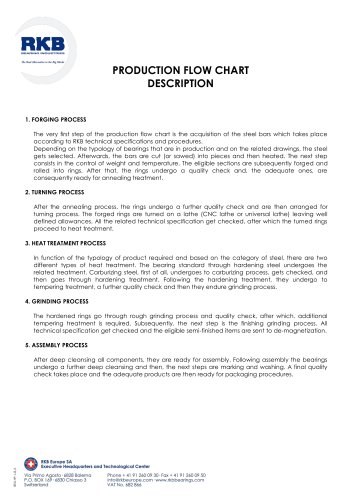

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages