Catalog excerpts

FOCUS: TRANSMISSION SYSTEMS FOR WIND TURBINES Developments and trends in wind turbine rolling bearings Cristina Bozan and Stefano Cugno RKB Bearing Industries has decided big capital investments on Research & Development in order to effectively satisfy the requirements of an increasingly demanding market such as that of the alternative energies and in particular wind energy. The sources of renewable energy are also named sources of alternative energy as the energy produced in this way is the main alternative for energy resulting from exhaustible sources. In the economy of this century, renewable energies are holding a prominent position. In particular, the wind energy has recently experienced remarkable spreading and establishing. Moreover, wind energy is inexpensive, inexhaustible and, which is not less important, clean. But the point is to remember that the wind energy plant, which is needed to capture this energy form, has also undesirable effects such as noise, occupancy of large areas of open space and visual impact on landscape. However, the helpful aspects of this type of application (for instance, the failed introduction of several million tons of pollutants and greenhouse gases into earth atmosphere) widely compensate for all possible drawbacks. In the last years almost all wind industry manufacturers have been focusing on producing innovative design turbines in order to permit their operation even at low wind speeds (3 m/sec) and generate higher and higher amounts of power. The improved design of blades, nacelle and speed multiplicators, which are less heavy, allowed to collect wind energy at higher altitudes thanks also to the increased capacity of the tower to support the weight of the entire system. “The Alternative Power” In an increasingly competitive sector, RKB Bearing Industries, with headquarters and technological division in Balerna (Switzerland), has decided heavy investments in their advanced engineering departments which by this time are an absolutely necessary element to effectively and efficiently answer to the requests of an increasingly demanding market like is that of the alternative energies. Moreover, quality of RKB products is based on an unceasing Research & Development activity as well as on the real idea that all the completed work has to lead to a constant progress both for the single as for the company. In order to boost and optimize wind energy applications, RKB engineers are using Dassault Systèmes software to create independent or interactive 3D models and discuss element properties against utilized material. Moreover, thanks to Ansys Workbench Platform software which permits FEM (Finite Element Method) analysis, designers can perform more complex and accurate simulations and assessments on bearing behavior and by means of dedicated hardware stations the processing time of models and simulations is shortened, product quality is increased and information to customers is more easily utilizable. Moreover, RKB Group technical departments also make large use of programs that have been purposely designed and developed to define bearing specific parameters, such as service life, force and stress distribution, misalignements, Hertzian loads and others. The RKB developed programs are extremely useful when designing and handling complex applications of wind energy as they allow to simultaneously consider many factors affecting bearing effectiveness (speed, moments, loads, oil and filter type, location on shaft, tolerance class, temperatures and so on). Obviously, all calculations are made according the most advanced and recent international standards. As it’s known, the service life of a wind turbine depends also on the life of bearings that have been utilized. For this reason the operation of wind turbine bearings should be efficient and reliable even in unfavourable environmental conditions. Due to the Single row full complement cylindrical roller bearings: conventional and with RKB AWT Technology treatment. 5 maggio 2010

Open the catalog to page 1

remarkable distorsions of the main shaft, it is generally better to use self-aligning roller bearings, particularly because they are able to stand exceptional radial loads and support large axial loads in both directions. Self-aligning roller bearings have two rows of rolling elements, one spherical race on the outer ring and two races on the inner ring that are positioned at a certain angle to bearing transverse axis. Generally, manufacturers of medium/high power (over 2 MW) wind turbines utilize speed multiplicators with a combination of one planetary unit and fixed axis gears or a...

Open the catalog to page 2All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

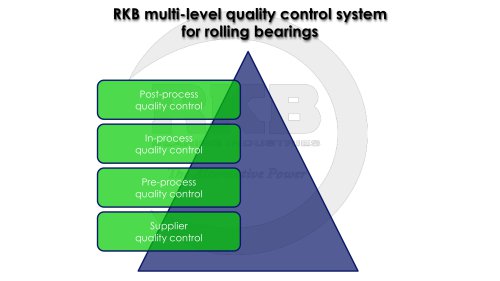

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

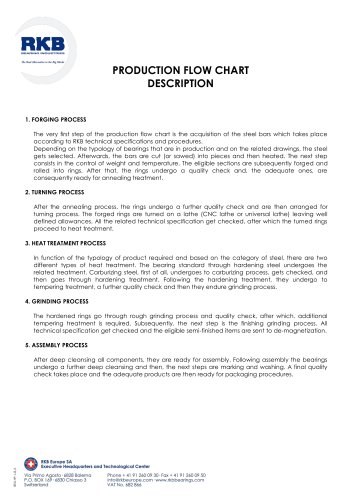

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages