Catalog excerpts

54 Organi di trasmissione - novembre 2010 BEARINGS Giangiacomo Colleoni and Giulio Bianchi As big size rolling bearings are going to play an essential role in proper operation of complex machinery, their design and production call for wise quality-oriented decisions by the manufacturer, under pain of unexpected faults or, still worse, machine downtimes. Big dimensions require expertise ason, it is a matter of primary importance to know the data of the application where the bearing will be mounted on (specifications, exploitation, technical diagram, load, speed, operating temperature, misalignments, lubrication type, etc.) in order to select the adequate product, mainly in terms of total cost of ownership, thus reducing at the minimum the risk of unsuitable parameters, which can cause serious drawbacks. In the light of the fact that big size bearings are going to carry out a criti- Big size rolling bearings for heavy industry are costly and require long production times and therefore long delivery times. As a result, users are generally anxious about having at their disposal the spare to be used in case of unexpected faults or damages which can lead to extremely long and burdensome machine downtimes when the backup part is not immediately available. For this re- Big size RKB bearings installed on a typical speed multiplicator for megawatt class wind turbines. 10 novembre 2010

Open the catalog to page 1

novembre 2010 - Organi di trasmissione 55 cal function for proper operation of complex expensive machinery, nothing can be left to chance and selections should be made with highest level of awareness and information. RKB Bearing Industries, the Swiss bearing manufacturer, has always been a specialist in all four main classes of radial and axial bearings (self-aligning, cylindrical roller, tapered roller and spherical roller bearings), with outside diameter up to 1,925 mm and mass of more than 4,000 kg. RKB defines as «T3» the segment containing its range of big size bearings, i.e....

Open the catalog to page 2

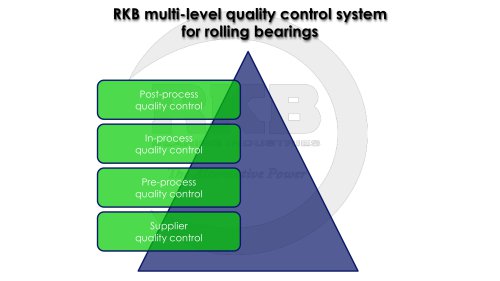

BEARINGS both after forging and heat treatments and rough-grinding, while MPI (magnetic inspection) is performed after finishgrinding. Furthermore, these procedures are assuring the Company Wide Quality Control, that is the constant real upgrading of each production cycle activity. Often customers ask the manufacturer of big size technological bearings for support during machinery design. This starts with technical analysis for the selection of the most suitable bearing type, coupling and lubrication to arrive at a real co-engineering activity that is performed by their respective technical...

Open the catalog to page 3All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

AF2D Multiroll Cage Design

2 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

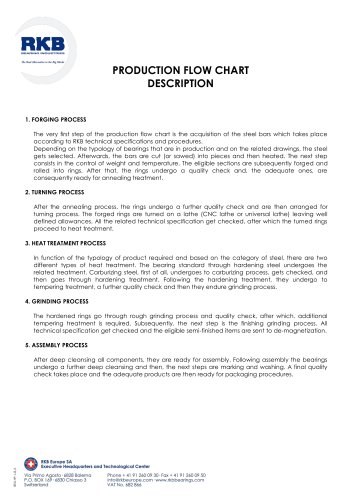

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages