Catalog excerpts

New RKB AF2D multiroll cage design COMMON PROBLEM RKB multiroll brass cage design A2D Mounting/Dismounting procedures Possible bearing cage failures/damages Harsh working conditions (high shocks, high vibrations, etc.)

Open the catalog to page 1

New RKB AF2D multiroll cage design RKB technological and metallurgical improvements NEW RKB AF2D DESIGN Main feature: • Machined steel cage design Main changes compared to A2D standard brass cage design: • • • • • • Improved cage resistance and tenon stiffness Reduced cage inertia Less sensitivity to chemical agents More free volume available for lubricant Less cage deformation which reduces the risk that rollers might fall Reduced max roller drop (suitable for oil lubrication)

Open the catalog to page 2All RKB Europe catalogs and technical brochures

-

Company Business Card - T3

1 Pages

-

Cylindrical rolelr bearings

2 Pages

-

Technological bearings

2 Pages

-

Project S12

2 Pages

-

RKB Product Table

2 Pages

-

This Is RKB

24 Pages

-

RKB Phosphate Treatment

2 Pages

-

RKB General Information Form

12 Pages

-

Project "241 KPP VL"

2 Pages

-

Project "EPB"

2 Pages

-

Project "MDU"

2 Pages

-

Project "ABI"

2 Pages

-

TQOS Maintenance

3 Pages

-

RKB_Europe_SA_ISO_9001

1 Pages

-

RKB_Europe_SA_ISO_14001

1 Pages

-

RKB_Europe_SA_OHSAS_18001

1 Pages

-

RKB_Europe_SA_ISO_27001

1 Pages

-

RKB_Europe_SA_ISO_10002

1 Pages

-

RKB_Europe_SA_ISO-TS_16949

1 Pages

-

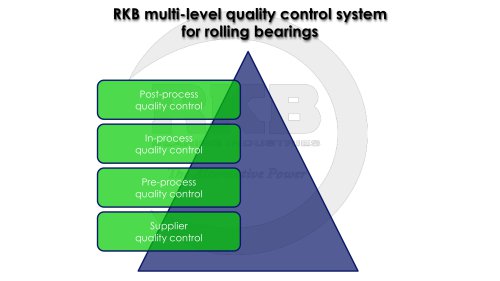

RKB General Quality Program

50 Pages

-

RKB Special Projects

68 Pages

-

RKB Metals Industry Leaflet

2 Pages

-

RKB Company Snapshot

2 Pages

-

RKB Brief Company Profile

2 Pages

-

RKB_Taper_Roller_Bearings_Assy

39 Pages

-

RKB Bearings Production Range

34 Pages

-

RKB Bearings Catalogue

168 Pages

-

RKB Taper Roller Bearings Assy

39 Pages

-

Made in RKB

1 Pages

-

RKB Basic Load Ratings

14 Pages

-

Why RKB

1 Pages

-

Bearing Industry Matrix

2 Pages

-

RKB Basic Information Form

1 Pages

-

RKB_Business_Card_T3

1 Pages

-

RKB_Business_Card_T2

1 Pages

-

RKB Message of the President

2 Pages

-

RKB Brief Introduction

2 Pages

-

RKB Digital Presentation

50 Pages

-

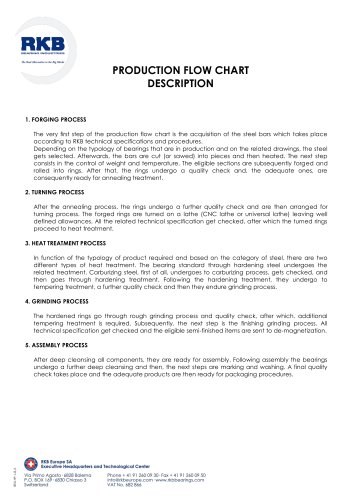

RKB PRODUCTION FLOW CHART

1 Pages

-

Company name and motto

6 Pages