Website:

RITMO S.p.A.

Website:

RITMO S.p.A.

Catalog excerpts

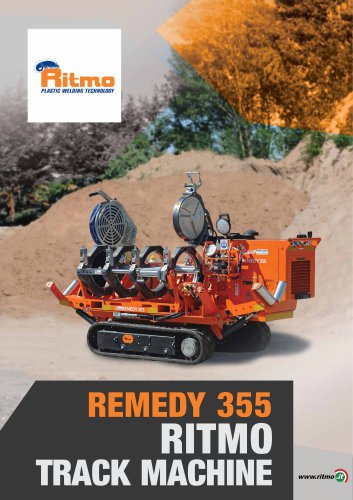

TRACK MACHINE

Open the catalog to page 1

SMALL DIAMETERS REMEDY 355 is an independent, high-productivity welding machine driven by tracks and powered by a Diesel on-board generator. Designed for butt welding HDPE and PP pipes from Ø 125 to 355 mm (from 4” to 14” IPS; from 4” to 12” DIPS). Suitable for ISO 21307 High Pressure and ASTM F2620 fusion standards. HIGH PRODUCTIVITY DIESEL ENGINE ON-BOARD GEN

Open the catalog to page 2

- Working range from Ø 125 to 355 mm from Ø 4” to 14”IPS from Ø 4” to 12” DIPS - Materials: HDPE, PP - Manual controls - Tracked welding machine - Drives over 35% slopes - In-ditch/user friendly - In-ditch hoses/cables range/length 7 m - 23 ft - Designed to weld according to: ISO 21307 High Pressure ASTM F2620 standards - Removable auxiliary panel to control facer/heating plate - Easily welds fittings/quick set-up time - Heating plate with a high temperature protection - Spotlights on welding area - Insert with fast-locking system - Self-propelled on track - Self-contained generator...

Open the catalog to page 3

Hydraulic Facer Heating plate with protection High intensity spotlights adjustable for welding area Control panel “Manual welding cycle” Removable body machine Control panel “hydraulic rollers” Electric box Hydraulic roller Drag Joining brackets Anchor holes Hydraulic roller Tracks Anchor holes Machine Carriage Easily Removable for In-Ditch Use Tracks along with an On-Board Gene

Open the catalog to page 4

Engine panel with hour counter, on board High intensity spotlights adjustable for welding area Hydraulic Facer Handgrip Heating plate Hydraulic rollers Electric box Engine access compartments Safety reflective strips

Open the catalog to page 5

Remedy 355 is available with Manual Welding Control System. Intuitive control panel allow an easy menagement of the welding cycle and every phase is manually controlled.

Open the catalog to page 6

REMEDY LINE TOTAL MOBILITY ON JOBSITE Remedy line are high-productivity welding machines driven by tracks. Design and Technology Made in Italy. FUSION SOLUTION LARGE - MEDIUM - SMALL REMEDY 1000 HDPE and PP pipes Ø 355 mm to 1000 mm 14” IPS ÷ 36” DIPS HDPE and PP pipes Ø 200 mm to 500 mm 6” ÷ 20” IPS 6” ÷ 18” DIPS

Open the catalog to page 7

Working range HDPE, PP For other materials contact RITMO S.P.A. Materials On board generator Emmission compliance Fuel 719 cc - 14 kW EPA US TIER 4 FINAL, UE STAGE V Diesel Fuel tank Hourly consumption Max operator side noise Tracks driving speed Width of tracks Max dimensions on site (W x D x H) Remedy 355 standard composition Weight boby machine for in-ditch use Weight Remedy 355 standard composition RITMO S.P.A Via A Volta, 35/37 - Bresseo di Teolo (Padova) Italy Ph. + 39 049 9901888 Fax +39 049 9901993 - info@ritmo.it - www.ritmo.it The information and photos in this publication are not...

Open the catalog to page 8All RITMO S.p.A. catalogs and technical brochures

-

PIPE SUPPORT

6 Pages

-

COMPACT LINE

8 Pages

-

BASIC 315 EASY LIFE

14 Pages

-

BASIC 250 EASY LIFE

14 Pages

-

BASIC 200 EASY LIFE

14 Pages

-

RADIUS-40-315

6 Pages

-

ALFA-200

9 Pages

-

ELEKTRA-500-1000

10 Pages

-

STARGUN - POLYFUSION

28 Pages

-

OMEGA 630-250

6 Pages

-

OMEGA 400-250

6 Pages

-

PIPE CUTTERS - SHEARS

5 Pages

-

ELEKTRA LIGHT

8 Pages

-

BASIC EASY LIFE

14 Pages

-

DELTA-630-ALL-TERRAIN

15 Pages

-

PLASTIC FABRICATION

33 Pages

-

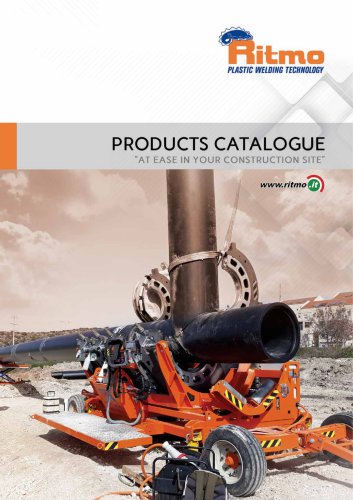

products catalogue

156 Pages