Website:

RINGSPANN

Website:

RINGSPANN

Catalog excerpts

Freewheels Backstops • Overrunning Clutches • Indexing Freewheels Edition 2019/2020 RINGSPANN® Registered trademark of RINGSPANN GmbH, Bad Hombu

Open the catalog to page 1

The maximum transmissible torques are 2 times the specified nominal torques. Issue 03/2019* Technical details subject to change without notice.

Open the catalog to page 3

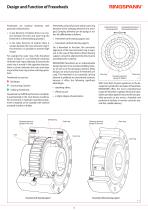

Design and Function of Freewheels Freewheels are machine elements with particular characteristics: • In one direction of rotation there is no contact between the inner and outer ring; the freewheel is in freewheeling operation. • In the other direction of rotation there is contact between the inner and outer ring; in this direction it is possible to transmit high torque. For example the outer ring of the freewheel shown in figure 4-1 can freewheel clockwise while the inner ring is stationary. If, however, the outer ring is turned in the opposite direction, there is contact between the inner...

Open the catalog to page 4

➧ Backstop Freewheels are used as backstops if reverse rotation of the operating direction is to be prevented. In many machines and installations, for technical safety or functional reasons, it is necessary to ensure that you are working in just one specified direction of rotation. This is why there are legal stipulations requiring a mechanical safety device for the operation of, e.g. conveyor systems. The normal operating mode of a backstop is freewheeling operation; the locking (torque transmission) is performed at zero speed. The immediate engagement of the clamping elements ensures the...

Open the catalog to page 5

Areas of Application for Freewheels ➧ Areas of application for Backstops Gear units Electric motors Gear motors Inclined conveyors Elevators Bucket elevators The backstop prevents reverse rotation in a drive of a conveyor installation if the power fails or the motor is turned off. The backstop prevents reverse rotation of the conveyor load if the power fails or the motor is turned off. ➧ Areas of application for Overrunning Clutches Textile machines Printing machines Fans Ventilators During normal operation of textile or printing machines, the overrunning clutch separates the barring drive...

Open the catalog to page 6

Fans Ventilators Pumps Compressors 3l The backstop prevents reverse rotation under the back pressure The backstop prevents reverse rotation under the back pressure of the conveyed medium if the motor is turned off. of the conveyed medium if the motor is turned off. Pumps Roller conveyor In multimotor drives the overrunning clutch disengages the inactive or lower speed drive. The overrunning clutch ensures that the conveyed material can be pushed or pulled faster over the rollers than the speed of the drive. Seed spreader High voltage switches The indexing freewheel replaces a...

Open the catalog to page 7

Complete Freewheels • With bearing support between inner or outer ring • Completely enclosed • With own lubrication • Connection to the outer ring and the customer part by: - bolting to the face (figure 8-1), - mounting flange, - keyway connection on the outer ring, - lever arm or - shaft coupling. Low Speed Backstop • With bearing support from inner to outer ring • Completely enclosed • With own lubrication Housing Freewheels • With bearing support between inner and outer ring • Completely enclosed by its own housing • With own lubrication • With bearing supported input and output shafts •...

Open the catalog to page 8

Basic Freewheels • With bearing support between inner and outer ring • For assembly with connecting parts • Lubrication - if necessary - to be provided by the customer Integrated Freewheels • Without bearing support. Concentric alignment of inner and outer ring must be provided by the customer. • Integrating the outer ring on the customer part by bolting to the face • Lubrication - if necessary - to be provided by the customer Internal Freewheels • Series both with and without bearing support. In the case of series without bearing support, concentric alignment of the inner and outer ring...

Open the catalog to page 9

Freewheels with Sprags or Rollers two different designs of freewheels Design as Sprag Freewheel The sprag freewheel has outer and inner rings with cylindrical tracks. The individually spring loaded sprags are arranged in between the rings. The freewheel locks without slipping. Different sprag profiles enable a multitude of types. Types are available for: • High torques • Contactless freewheeling operation • High indexing accuracy 10-1 Function of Sprag Freewheels With the sprag arrangement illustrated in figure 10-2 the outer ring can be turned freely clockwise (freewheeling operation), if...

Open the catalog to page 10

Design as a Roller Freewheel With roller freewheels either the inner or the outer ring has roller ramps. The other ring has a cylindrical track. The individually spring loaded rollers are arranged in between the rings. The freewheel locks without slipping. Function of Roller Freewheels With the version illustrated in figure 11-2, the outer ring can be turned freely clockwise (freewheeling operation), if the inner ring Locking direction or driving operation Freewheeling direction or freewheeling operation • is at a standstill, • is turned counterclockwise or Spring force Outer track • is...

Open the catalog to page 11

In addition the standard type, RINGSPANN has vice life for freewheels with sprags. The table conditions for these types. developed four other types for extended ser- above lists the recommended application Type with sprag lift-off X The sprag lift-off X is used for backstops and overrunning clutches, provided that in freewheeling operation the inner ring is rotating at high speed and providing with overrunning clutches that the driving operation is conducted at low speed. In freewheeling operation, the centrifugal force Fc causes the sprag to lift off from the outer track. In this...

Open the catalog to page 12

Type RIDUVIT® RINGSPANN sprags are made from chrome steel, the same material as used for the balls in ball bearings. The high compressive strength, elasticity and tensile strength of this material is required for the sprags in a locked state. In freewheeling operation, however, it is able to cope with utmost wear resistance on the points of contact of the sprag with the inner track. All of these requirements are perfectly fulfilled by using a chrome steel sprag with RIDUVIT® coating. The RIDUVIT® coating lends the sprag a resistance to wear akin to that of hard metal. The technology used...

Open the catalog to page 13All RINGSPANN catalogs and technical brochures

-

MV 033 FEM

8 Pages

-

DH 035 FPM / FPA

2 Pages

-

DV 020 FHM

1 Pages

-

DH 020 FHM

1 Pages

-

DV 030 FHM

1 Pages

-

DH 030 FHM

1 Pages

-

DV 030 FHA

1 Pages

-

DH 030 FHA

1 Pages

-

DV 035 FHM / FHA

1 Pages

-

DH 035 FHM / FHA

1 Pages

-

DU 060 FHM

2 Pages

-

DH 020 FKM

1 Pages

-

DH 005 PFK

1 Pages

-

DV 020 FKM

1 Pages

-

DH 010 PFK

1 Pages

-

DH 015 PFK

1 Pages

-

DH 020 PFK

1 Pages

-

DV 030 PFM

2 Pages

-

DH 030 PFM

2 Pages

-

DV 035 PFM

2 Pages

-

DH 035 PFM

2 Pages

-

DU 060 PFM

2 Pages

-

DH 010 MSM

1 Pages

-

DV 020 MSM

1 Pages

-

DH 020 MSM

1 Pages

-

DV 020 MKM

1 Pages

-

DH 020 MKM

1 Pages

-

HW 075 FHM

2 Pages

-

HS 075 HFK

2 Pages

-

DV 020 FEM

1 Pages

-

HW 040 HFA

1 Pages

-

DV 020 PFK

1 Pages

-

BCS 600

4 Pages

-

DS

2 Pages

-

DU 060 FPM

2 Pages

-

HW 075 HFK

2 Pages

-

HS 120 HFK

2 Pages

-

KE … FPK series

2 Pages

-

RLK 603 S

4 Pages

-

RLK 603 K

3 Pages

-

RLK 608 series

3 Pages

-

RLK 606 series

3 Pages

-

RLK 110 series

2 Pages

-

RLK 110 K series

2 Pages

-

RLK 130 series

2 Pages

-

RLK 131 series

2 Pages

-

RLK 132 series

2 Pages

-

RLK 133 series

2 Pages

-

RLK 200 series

2 Pages

-

RLK 250 series

2 Pages

-

RLK 603 series

4 Pages

-

HW 100 HFA

2 Pages

-

KE … FHK series

2 Pages

-

HI 150 HUK, HI 180 HUK

2 Pages

-

FN series

2 Pages

-

HW 150 HFA / HW 180 HFA

2 Pages

-

DT

2 Pages

-

HW 063 HFA

1 Pages

-

RLK 250 L series

2 Pages

-

RLK 350 series

2 Pages

-

RLK 402 series

2 Pages

-

RLK 404 series

2 Pages

-

FD series

2 Pages

-

RLK 300 series

4 Pages

-

Trantorque Mini

2 Pages

-

Trantorque OE

2 Pages

-

SIKUMAT® SC

6 Pages

-

SIKUMAT® SG

6 Pages

-

SIKUMAT® ST

6 Pages

-

SIKUMAT® SN

6 Pages

-

SIKUMAT® SA

6 Pages

-

SIKUMAT® SU

6 Pages

-

SIKUMAT® SR

6 Pages

-

SIKUMAT® SB

6 Pages

-

SIKUMAT® SL

6 Pages

-

RIMOSTAT® RS

4 Pages

-

RSHD series

2 Pages

-

RT

2 Pages

-

PA series

4 Pages

-

RFK … TBO series

2 Pages

-

RWK … EEO series

2 Pages

-

RDA … ESO Series

2 Pages

-

RDZ … DTO Series

2 Pages

-

RDZ … DFO Series

2 Pages

-

RDZ … EEO Series

4 Pages

-

RDL … DSO Series

2 Pages

-

RDL … DSZ Series

2 Pages

-

RDL … DSA Series

2 Pages

-

REB … DCO Series

4 Pages

-

REK … DQO Series

6 Pages

-

REK … DGO Series

4 Pages

-

REK … DHO Series

4 Pages

-

REK … DGZ Series

4 Pages

-

REK … DCO Series

8 Pages

-

HDDS series

2 Pages

-

REK … ECO Series

2 Pages

-

LAFF series

2 Pages

-

BKFF series

2 Pages

-

HKFF series

2 Pages

-

KFFF series

2 Pages

-

LBDF series

2 Pages

-

BKDF series

2 Pages

-

HKDF series

2 Pages

-

KFDF series

2 Pages

-

BKDI series

2 Pages

-

SKDZ series

2 Pages

-

Pull Only Cables

8 Pages

-

FZ … series

6 Pages

-

Energy Generation

7 Pages

-

Shaft-Hub-Connections

100 Pages

-

Freewheels_2024-2025

112 Pages

-

Industrial Brakes_2022-2023

200 Pages

-

DV 035 FPM / FPA

2 Pages

-

DH 030 FPA

2 Pages

-

DV 030 FPA

2 Pages

-

DH 030 FPM

2 Pages

-

DV 030 FPM

2 Pages

-

DH 020 FPM

1 Pages

-

DV 020 FPM

1 Pages

-

DH 010 FPM

1 Pages

-

DH 012 FEM

1 Pages

-

IR series

2 Pages

-

SF … P series

2 Pages

-

SF series

2 Pages

-

FNR series

2 Pages

-

FSN series

2 Pages

-

FRHN

2 Pages

-

FDN series

2 Pages

-

FCN … R series

2 Pages

-

FXN series

4 Pages

-

FON series

2 Pages

-

FXM series

6 Pages

-

FGR … R series

2 Pages

-

FH series

4 Pages

-

FRHD series

2 Pages

-

FBL series

2 Pages

-

FBE series

2 Pages

-

FAV series

2 Pages

-

FA series

2 Pages

-

FGR … R A2A3 series

2 Pages

-

FGR … R A3A4 series

2 Pages

-

BC series

2 Pages

-

BA series

2 Pages

-

FGRN R A5A6 series

2 Pages

-

BM series

2 Pages

-

FGR R A2A7 series

2 Pages

-

FGR R A1A2 series

2 Pages

-

FBF series

2 Pages

-

Company brochure

7 Pages

-

FR series

2 Pages

-

FB series

2 Pages

-

Integrated Freewheels FXRU

3 Pages

-

Integrated Freewheels FXRW

3 Pages

-

Integrated Freewheels FON

2 Pages

-

Integrated Freewheels FXM

6 Pages

-

Energy Generation

7 Pages

-

Mining

9 Pages

-

Food and packaging machines

7 Pages

-

Machine tools

7 Pages

-

Shaft Couplings 2018/2019

76 Pages

-

RCS® Remote Control Systems

64 Pages

Archived catalogs

-

Freewheels_2020-2021

112 Pages

-

Mining 07/2020

9 Pages

-

RCS® Remote Control Systems

64 Pages

-

2020 Machine Tools

7 Pages

-

Shaft Couplings

76 Pages

-

Industrial brake

184 Pages

-

Industrial Brakes

184 Pages

-

Overload Clutches

80 Pages

-

Precision Clamping Fixtures

100 Pages