Website:

RIFTEK EUROPE

Website:

RIFTEK EUROPE

Catalog excerpts

Laser Systems for Inner Diameter Control

Open the catalog to page 1

RIFTEK RIFTEK company was founded in 1993. The enterprise specializes in development and fabrication of optoelectronic instruments for measuring of geometrical quantities. The basic product line includes: laser triangulation position sensors; 2D and 3D laser scanners; optical micrometers; absolute linear encoders; hardware and software systems for welding robots; specialized systems for measurement dimensions displacements and distance, thickness, diameter, ID and etc.; measurement instruments for railway transport; machine vision systems. RIFTEK products are delivered in more than 70...

Open the catalog to page 2

Automated systems for Inner Diameter Control. PURPOSE OF SYSTEMS The systems are designed for contactless measuring of inner diameter and profiles of cylindrical and taper pipes, gun barrels, extruders, progressive cavity stators, turbodrills and so on. MEASURED PARAMETERS ID, Ovality, Roundness, Cylindricity, Conicity, Concentricity We offer systems based on TWO WORKING PRINCIPLES Multi-sensor measurement by stationary laser sensors Inner surface laser scanning with rotating sensors SYSTEMS PARAMETERS Measured ID – from 9 mm Up to ± 2 um accuracy Up to 32000 measured points on...

Open the catalog to page 3

The basic elements of ID measurement systems. THE SYSTEMS USUALLY CONTAIN: Laser measurement head with • stationary sensors or • rotating sensors (point or 2D) Translation module, intended for transportation of measurement head inside the pipe: • self propelled or • any kind of pulling machine or rod Software for PC Calibration master-rings THE SYSTEMS CAN CONTAIN: Centering frame to hold measurement head near pipe axis OPTIONS: Pipe straightness measurement module Video inspection module Wireless connect

Open the catalog to page 4

Multi-sensor measurement heads, RF040 Series. Structure and operational principle. THE MEASUREMENT head CONTAINS: usually 6 laser triangulation sensors, located circumferentially in one housing at known fixed angles. THE SYSTEM OPERATES AS FOLLOWS The measurement head is inserted into the pipe and moved by translation module to the definite position. Calibrated laser sensors measure distances to the inner surface Software calculates inner diameter of the pipe

Open the catalog to page 5

Rotating laser measurement head. Structure. THE MEASUREMENT HEAD USUALLY CONTAINS: laser triangulation sensor 1 (one or several pieces with different measurement range and stand-off distance), mounted on rotating platform 2, with motor 3, electronic driver 4 and rotary encoder 5, coupled to the motor 3. The system can also includes a tilt sensor 6, intended for control of inclination of rotating platform during measurement. Options: in-built Wi-Fi module 7 is used for communication between the system and PC; the system can be powered from internal batteries 8. 2D laser scanner can be...

Open the catalog to page 6

Rotating sensors measurement heads RF096 Series. Operational principle. THE SYSTEM OPERATES AS FOLLOWS: The measurement head is inserted into the pipe and moved to the definite position. Rotating laser sensor scans inner surface of the pipe and the head transmits polar coordinates of the surface (distance from rotation axis, measured by triangulation sensor and a corresponding angle, measured by encoder). Software uses the set of transmitted coordinates to calculate: ID of measured pipe ovality and roundness to find surface defects to design full profile in definite section. 3D model of the...

Open the catalog to page 7

ID measurement by Multi-sensors systems APPLICATIONS.

Open the catalog to page 8

Multi-sensor laser system for fiberglass pipes deformation measurement. Six triangulation sensors inside Diameter range – 500…1250 mm Accuracy - +\-

Open the catalog to page 9

Multi-sensors systems. Designed for ID measurement of nuclear Power station pipes Four laser sensors inside Diameter of the module: 70 mm Measured diameters: 95…195 mm (main range), 160…300 mm (extended range) Accuracy: 0,05 mm (main range) and 0,2 mm (extended range) Designed for robotic measurement of engine cylinders ID Six laser sensors inside Diameter of the module: 60 mm Measured diameters: 70…80 mm Acc

Open the catalog to page 10

Multi-sensors systems. Designed for ID measurement of pipes Six laser sensors inside Diameter of the module: 60 mm Measured diameters: 65…115 mm, Accuracy: ±25 um Designed for honing machines Six laser sensors inside In-built battery, Wi-Fi data transfer Measured diameters: 100…150 mm, Ac

Open the catalog to page 11

ID measurement by Laser Scanning. Sensors and Systems.

Open the catalog to page 12

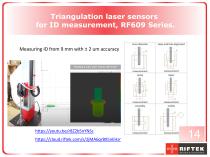

Triangulation laser sensors for ID measurement, RF609 Series. Smallest triangulation sensor on the market, sensor body diameter = 8.5mm, measured ID – from 9 mm Sensors with in-built slip-ring Sensors with battery supply and Wi-Fi data transfe

Open the catalog to page 13

Triangulation laser sensors for ID measurement, RF609 Series. Measuring ID from 9 mm with ± 2 um accuracy

Open the catalog to page 14

Triangulation laser sensor RF609-Wi-Fi. ID measurement for CNC machines. ID range 9…19 mm or customized Accuracy ±2 um Sensor parameters can be changed on request

Open the catalog to page 15

Measurement kit for Heat Exchanger Tube Sheet control on the base of RF609-Wi-Fi sensors. ID range 9…19 mm and 16…46 mm Accuracy ±5 um and ±12 um Measurement cycle 5 s Sensor parameters can be changed on re

Open the catalog to page 16

RF096 systems for ID measurement. Customized versions for stationary or robotic solutions. ID range Accuracy Resolution Measurement speed https://youtu.be/UbF1E1Hjz5E 70…160 mm ±0.05 mm 2048 points for cross-section 4 cross-sections/s https://cloud.riftek.com/s/Kei5yrBLiHefLp8 ID range Accuracy Resolution Measurement speed Systems parameters can be changed on request

Open the catalog to page 17

Robotic measurement of Stepped holes RF096-15/40-50/70 system. two stages measuring head with three laser sensors inside Range 14…40 mm Accuracy ±20 um Range 50…70 mm Accura

Open the catalog to page 18

RF096 systems for ID measurement. Customized versions with centering frames. Designed for extruder barrels inspection ID range 40…95 mm Accuracy ±0.005 mm Control of wearing status, roundness, ID Designed for tubes inspection ID range Accuracy Resolution (cross-section) Speed

Open the catalog to page 19All RIFTEK EUROPE catalogs and technical brochures

-

PRODUCT CATALOG 2025

44 Pages

-

RF603 Series Manual

49 Pages

-

RF602 Series Manual

33 Pages

-

RF603HS Series Manual

36 Pages

-

RF609 (RF609Rt) Series Manual

33 Pages

-

RF600 Series Manual

46 Pages

-

RF605 Series Manual

29 Pages

-

RF60i Series Manual

46 Pages

-

RF62x Manual

174 Pages

-

RF25x Series Manual

34 Pages

-

RF651 Series Manual

32 Pages

-

RF656 Series Manual

32 Pages

-

RF656XY Series Manual

33 Pages

-

Laser probes Manual

14 Pages

-

Pipe ID Control System Manual

18 Pages

-

Edge Sensor RF659 Series Manual

25 Pages

-

RF627Smart-Weld manual

103 Pages

-

PRODUCT CATALOG 2024

40 Pages