Catalog excerpts

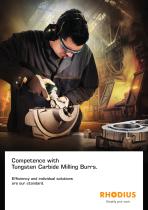

Competence with Tungsten Carbide Milling Burrs. Efficiency and individual solutions Simplify your work.

Open the catalog to page 1

Sustainable solutions are created when experience meets practical know-how. The expertise from many heads is embodied in every RHODIUS burr, namely that of our qualified work force in customer service, development and production, but above all, the application demands and application diversity of our customers. They repeatedly present us with new challenges and give us the impetus for innovative top efficiency. This practical slant, paired with our production know-how, is what makes it possible to deliver clever product solutions which achieve top results, increase the productivity of your...

Open the catalog to page 2

RHODIUS is right at home where custom solutions are the standard. The bandwidth for various workpiece specifications is enormous. So are the requirements for their machining. Every product geometry and workpiece type requires special head shapes and serrations to achieve top results and a high level of efficiency in the machining process. RHODIUS always focuses on both of these. A solution is only considered to be an ideal solution once the material quality, parts geometry, machine and milling burrs are perfectly adapted to one another. We are happy to analyse your particular application...

Open the catalog to page 3

Tungsten carbide burrs Fine precision Precision is the key performance criteria for carbide burrs. This is why Rhodius carbide burrs are manufactured on the most modern CNC machines. The outstanding accuracy of these machines guarantees the constant high quality of the tool. Our carbide burrs are characterised by a high concentricity and perfectly matched cutting shape. For spoton working results. The right cut The following basic rule applies: the harder the material to be processed, the finer the cut. Preferred application Recommended working speed [m/min] unalloyed steels/cast steel for...

Open the catalog to page 4

The recommended operating speed In order to achieve optimum working results and long lifetimes, the choice of an optimum speed is also of decisive importance. If the speeds are too low, this leads to erratic running and cavities. The consequenze is premature wear of the carbide burr. Knocking and chattering of the carbide burr also greatly reduces the lifetime. This is why you should only use truerunning chucks. Safety tips concerning long-shanked tungsten carbide burrs When working with long-shanked tungsten carbide burrs, please remember to insert the die into the workpiece before...

Open the catalog to page 5

The correct head shape is decisive The right tool for every application The choice of head shape is determined by the machining that must be done and the workpiece geometry. The most common machining processes are burr removal, milling for surface welding, re-working of welded seams, cleaning of castings and the machining of contours. It is necessary to select the milling head suitable for the contour that is to be machined, its accessibility and characteristics. The overview can assist you with selecting the suitable head shape: Milling cutter name: Form A: Cylinder without end cut Carbide...

Open the catalog to page 6

Tungsten carbide burrs Efficiency due to maximum lifetime Learn how to improve the performance of your tungsten carbide burrs through correct handling here. Application instructions for the ideal use of tungsten carbide burrs Problem Unsatisfactory removal Serration not adapted to material being machined Adapt type of serration according to table Unsatisfactory ease of cutting Adjust rotational speed Overheating of tool/ blue discolouration Rotating speed is too high Adjust rotational speed Drive unit off-centre Replace drive unit Clamping surface too small Increase clamping length Contact...

Open the catalog to page 7

Form A: Cylinder without end cut 3 x 14 x 3 x 38 Form B: Cylinder with end cut 3 x 14 x 3 x 38 Form C: Ball nosed cylinder 3 x 14 x 3 x 38

Open the catalog to page 8

Form F: Ball nosed tree 3 x 14 x 3 x 38

Open the catalog to page 9

Form L: Ball nosed cone 3 x 14 x 3 x 38

Open the catalog to page 11

Form N: Inverted Cone 3 x 4 x 3 x 38

Open the catalog to page 12

General notes: Information on the scope of delivery, appearance, performance and dimensions of the tool are true for the time of printing. Errors and omissions exepted. No liability for misprints. Copying, reprinting, storage or publication only with the express consent of RHODIUS Schleifwerkzeuge GmbH & Co. KG, Brohltalstraße 2, 56659 Burgbrohl (Germany). Burgbrohl, October 2015 Picture credits: Fotolia RHODIUS

Open the catalog to page 14

colour codes Resin-bonded grinding tools and miscellaneous Non-ferrous Cast-iron Form according to norm DIN for tungsten carbide burrs Straight grinder Protective gloves Dust protection Iron and sulphur free < 0.1 Quality system . Very innovative products with a unique prob- lem-solving competence. High-performance tools with ceramic grain. For industrial applications with a very large amount Best products for their category for maximum p. For particularly high demands and frequent use ALPHALINE ©OO Efficient grinding tools for the cost-conscious. Product details Article/order number...

Open the catalog to page 15

tungsvollen Quellen RHODIUS Schleifwerkzeuge GmbH & Co. KG industry@rhodius.de • www.rhodius-abrasives.com Simplify your work.

Open the catalog to page 16All RHODIUS catalogs and technical brochures

-

NO MERCY FOR METAL

32 Pages

-

XT10

2 Pages

-

XT24

2 Pages

-

XTK35 CROSS

1 Pages

-

XT70

2 Pages

-

XTK70

2 Pages

-

Catalog 2018

280 Pages

-

FUSION

2 Pages

-

CROSS

2 Pages

-

EXACT

2 Pages

-

VISION

2 Pages

-

RHODUCER

2 Pages

-

GD200 IMPULS

2 Pages

-

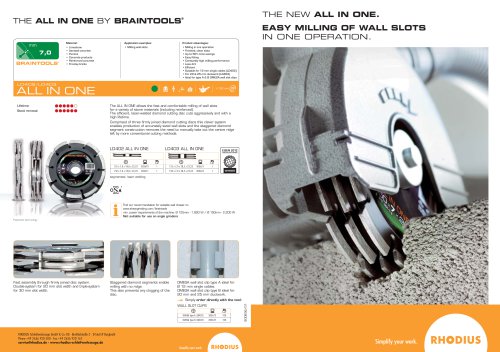

ALL IN ONE

2 Pages

-

HydroProtect

2 Pages

-

Polishing

8 Pages

-

CERAMICON

12 Pages

-

Flyer Polishing

8 Pages

-

Catalogue 2015/2016

202 Pages

Archived catalogs

-

Catalogue 2013/2014

186 Pages

-

About Rhodius

1 Pages

-

Rhodius RS39 HURRICANE

1 Pages