Website:

RENK GmbH

Website:

RENK GmbH

Group: MAN

Catalog excerpts

Innovative Power Transmission Calibration Diagram PressureMpa TorqueNm 1008060 40 20 HYGUARD > Safety Couplings > ownerΒs choice size="-3">

Open the catalog to page 1

The main task of overload protection systems being installedin the drive of machineries is to safeguard valuable industrialgoods against unexpected overload stresses. Inspite of conti-nuous modernization and technical advance of drive systems,the risk of such damages has not become less, but even bigger.The reason for this is the growing pressure which competitionis exerting on plant and machinery manufacturers, and thethereby resulting necessity to continuously optimize their pro-ducts. Over-dimensioning of vital components is no longerdeemed as necessary as it used to be in the past....

Open the catalog to page 2

ensure a maximum of reliability. Thecombination of the HYGUARD > ή Systemwith the proven curved tooth couplingworks like a safety coupling with torquelimitation. The release torque is adjusta- ble and remains constant for the entireoperation time. The reliable protectionfor valuable machinery.Advantages of HYGUARD > Safety Couplings: Transmission of high torques withinlittle space ● Torsionally rigid flexible connectionof shafts ֢ Overload protection with adjustabletorque limitation ● Constant release torque over the entire duration of operation ● No interruption of operation due...

Open the catalog to page 4

is given by the safety disconnection, theessential components of which are theshear ring and the shear tube. There is afirm connection between shear ring and shaft, whereas the shear tube is accom-modated in the movable part. If theoperating torque exceeds the presetvalue, the safety element will slip on theprofiled surfaces and the shear ring cutsoff the top of the shear-tube. The systemis depressurized within milliseconds andthe connection is released. > The HYGUARD > Safety Coupling iseasy to activate again. A high-pressurepump with pressure gauge for pressuresetting and hydraulic oil...

Open the catalog to page 5

1Remove old shear tube. 2Screw-in new shear tubeand tighten it firmly. 3Remove sealing plug frominjector connection. 4Connect pump, loosenshear tube by 1/4 turn. 5Pump up until requiredpressure is reached, > re-tighten shear tube firmly. 6Relief pressure in pumpand disconnect the same. Insert sealing plug into injector connection. > ▲ PressureMPa 100806040 20TorqueNm ▲ Various shear tubes and screw plugs 6RENK Aktiengesellschaft, Rheine Works Phone: +4959717900 Fax: +495971790208and 790256 >

Open the catalog to page 6

In both cases, the calculationmust result in a value whichmeets the following condition: Sequence of Release > Cut-off torque Depending on the applicati-on, HYGUARD > safety cou-plings are supplied with stan-dard slide bearings, or withbuilt-in roller bearings. As far as the slide bearingoptions are concerned, therelevant restrictions and limi- tations have to be observedin order to avoid wear and unacceptable heating. Assuch, the sliding velocityafter release shall not exceed the value of 1,5 m/s. A maxi-mum value of 1 N/mm > 2 If this value is exceeded, thenext larger size, or a...

Open the catalog to page 8

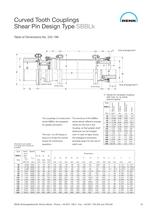

TypePitchSize ofDepth of BW CircleThreadThreadefg Size mmNumbermm 60 404xM815 70 504xM815 80 554xM815 >

Open the catalog to page 15

grease nipplescrew plugscrew plug > 1 Type SBBLk > 1) 1) Mass Momemtof Inertia Grease Quantity CouplingGrease QuantityBall BearingWeight Sizekgm > 2 kgkgkg 38 0,0110,0850,026,0 >

Open the catalog to page 25

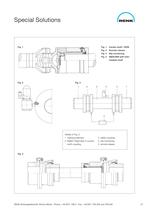

Fig. 1 Fig. 2 Fig. 4 Fig. 3 Fig. 1Cardan shaft / HDWFig. 2Remote releaseFig. 3Slip monitoringFig. 4SBGk/BW with inter-mediate shaft Details of Fig. 3 1clamping element2Raflex > Steel disk or curvedtooth coupling3safety coupling4slip monitoring 5remote release RENK Aktiengesellschaft, Rheine Works η Phone: +4959717900 Fax: +495971790208and 79025627 >

Open the catalog to page 27

All the required tools to facili-tate the assembly andcommissioning of the safetycouplings are included in a solid Service Box.The Service Box contains ahigh-pressure pump withhand lever (RT 100). It workslike a piston pump and isequipped with a pressuregauge. The pump is also pro-vided with a pressure valveso that the operating pres-sure can be pre-set to therequired value. This offersparticular advantages, ifseveral safety couplings areoperating in one plant at thesame service pressure.The large Service Box alsoincludes a high-pressurepump with hand lever (RT2000), which is particularly...

Open the catalog to page 29

Car manufacturers use HYGUARD > Safety Couplings in theirgearbox test stands. Due to the rapid and safe decoupling ofthe gearbox in the event of cut-off, this safety coupling hasproved itself as an extremely effective protection for the valuable measuring facilities. The test equipment consists ofan electric motor, an electric brake and the gearbox to betested. The measuring equipment is integrated in the test set-up. The units to be tested are started up to the individual gearspeeds with gradually increasing load.In case of failures, the gearbox has to be immediately dis-connected from the...

Open the catalog to page 30

1 1HYGUARD > safety coupling infour high-stand reversing millshown on photo 42Twenty roll-cold rolling mill with HYGUARD > ή safety coupling inthe twenty roll-cold rolling millshown on photo 24Four high-stand reversing millwith HYGUARD > safety coupling inthe main drive between motor and gearbox3HYGUARD > ή safety cou-pling in the main drive between motor and pinion stand gearbox > 2 3 4

Open the catalog to page 31

1 Curved tooth coupling Type SB2 High-speed gearbox Type THGD-9003 Curved tooth coupling Type SBk4 Raflex > flexible steel disk coupling Type MTP acc. to API 610 >

Open the catalog to page 32All RENK GmbH catalogs and technical brochures

-

Gear Units for LNG Carriers

7 Pages

-

Single Marine Gear Solutions

7 Pages

-

AX-BO® and RAFINEX®

8 Pages

-

Bogenzahn-Gelenkspindeln®

12 Pages

-

Curved Tooth Couplings

52 Pages

-

HSWL 295

2 Pages

-

RK 304

2 Pages

-

Turbo Gear Units

4 Pages

-

Codad Predator

2 Pages