Website:

REMBE® GmbH Safety+Control

Website:

REMBE® GmbH Safety+Control

Catalog excerpts

REMBE® PROCESS SAFETY Pressure and Vacuum Relief Consulting. Engineering. Products. Service

Open the catalog to page 1

REMBE® PROCESS SAFETY – THE SAFE CHOICE FOR PRESSURE AND VACUUM REMBE® has been a global market leader in the area of pressure relief for over 45 years. As well as a comprehensive range of consulting services we also supply a broad spectrum of state-of-the-art rupture discs for a variety of applications in many different sectors. These include the Oil + Gas, Petrochemical, Aerospace and Pharmaceutical Industries, Food Processing sectors and Medical-Technical systems among others. Our rupture discs are always manufactured individually to meet the specific existing requirements of our...

Open the catalog to page 2

Process safety basics 4 The world's first reusable rupture disc For applications with strict hygiene requirements For isolating safety valves For installation directly between flanges The reverse acting rupture disc with the patented manufacturing process Flat rupture discs Single layer rupture discs 21 The father of all rupture discs Bidirectional rupture discs 22 For the plastics and food processing industries For low burst pressure and high vacuum Plug type rupture discs 27 HPRD high pressure rupture discs 28 For high pressure and extreme temperatures Extruder rupture discs 28 Rupture...

Open the catalog to page 3

PROCESS SAFETY BASICS The dangers of excessive pressure What is a rupture disc? Overpressure and vacuum are characteristics of virtually every production process. If the pressure rises above or falls below the specified limits, major damage to plant components may result. The consequences are production standstills and serious commercial losses. A reliable and fast reacting pressure relief system is therefore essential to protect the plant in case the pressure rises above or falls below these limits. Rupture discs are non-reclosing safety devices with precisely defined breaking points. They...

Open the catalog to page 4

• Instant response - nothing reacts faster than a rupture disc. Excessive overpressure and vacuum is relieved in milliseconds. • Full bore opening available for pressure relief -the entire cross-section is used for fast and safe pressure relief. • Leak-tight - prevents process media from escaping during normal operation and thus reduces the costs and problems associated with such losses. • Economic solution - significant cost savings compared to other safety systems for pressure relief. What should I be aware of when selecting a rupture disc? Reliable and cost-effective REMBE® rupture discs...

Open the catalog to page 5

Our mission: your safety Operational safety is an important responsibility. In fact, it’s a mission to which we’ve dedicated ourselves wholeheartedly for over 40 years now. Throughout the world our experts have a single aim – to provide the best possible protection for your systems and processes. You’ll benefit from our decades of experience which ensures that you always receive an honest analysis and products of the highest quality. Working diligently and responsibly, our attention is fully focused on the customized optimization of your routines, manufacturing processes and products. We...

Open the catalog to page 6

LIFE. A decision to purchase REMBE® means opting for perfect safety. You will always have the support of our experts in matters of process safety and explosion safety technology-24/7, all year round. It's our promise! Our products are not just excellent. They are approved and certified. Downtime costs money. Our service never stands still – throughout the world. Good is never good enough for us. And so we keep putting ourselves to the test. The result is safety products licensed under globally recognized and industry-specific standards and regulations. Moreover, we are the first company...

Open the catalog to page 7

Reverse acting rupture discs REVERSE ACTING RUPTURE DISCS Maximum reliability at high standard operating pressure ratios Reverse acting rupture discs are installed with the domed side of the rupture disc facing the process. In this configuration, the rupture disc offers a higher standard operating ratio and better vacuum resistance. It is more resistant, more rugged and gives a longer service life. A higher standard operating ratio allows you to operate your system under a higher load without the risk of fatigue or premature opening of the rupture disc. Since REMBE® rupture discs have an...

Open the catalog to page 8

Reverse acting rupture discs KUB® The world’s first inspectable rupture disc KUB® is the most rugged rupture disc currently available. KUB® is not only extremely easy to install – it is also simple to remove and reinstall. In addition to a standard operating pressure ratio of up to 98 %*, the design is robust enough to cope with incorrect handling before and during installation. The IG holder also helps in this regard (see page 33). The rupture disc and holder are designed to ensure that it is impossible to insert the rupture disc incorrectly. KUB® does not use bite-type seals. Instead it...

Open the catalog to page 9

For operators this means: • imple, quick and torque-independent installation of the S rupture disc without special tools. • o risk of premature opening or damage to the rupture disc. N • onger service life of the rupture disc reduces the costs L associated with production downtime, maintenence and replacement discs. Using Leonard Euler’s formula, we developed a unique cut profile – known as buckling pins – for the KUB’s rupture element. Careful selection of the buckling pin geometry and arrangement in combination with the material of the rupture disc offer accurate control of the response...

Open the catalog to page 10

32" " *Company Names ortrademarks combined with material descriptions are only used for description purposes. The product promoted is not product of the respective companies and trademarks. Different sizes, pressure classes, temperatures, materials and fittings available on request.

Open the catalog to page 11

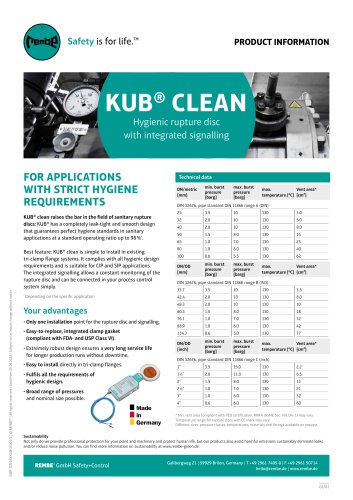

KUB® CLEAN For applications with strict hygiene requirements KUB® clean raises the bar in the field of sanitary rupture discs: KUB® has a completely leak-tight and smooth design that guarantees perfect hygiene standards in sanitary applications. Best feature: KUB® clean is simple to install in existing tri-clamp flange systems. It complies with all hygienic design requirements and is suitable for CIP and SIP applications. The unique construction of the KUB® with its totally smooth sealing membrane means that the rupture disc has no score lines, indentations or notches on the process side,...

Open the catalog to page 12All REMBE® GmbH Safety+Control catalogs and technical brochures

-

PROCESS SAFETY

40 Pages

-

Explosion Safety

56 Pages

-

KUB® CLEAN

2 Pages

-

FARADO® I

2 Pages

-

SINGLE LAYER RUPTURE DISC

2 Pages

-

KUB®

5 Pages

-

Explosion Venting ETX™

2 Pages

-

KUB® Product Information

3 Pages

-

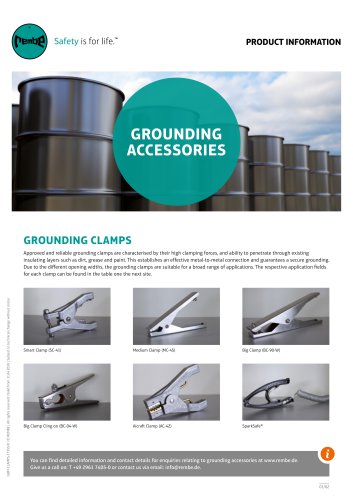

Grounding Accessories

2 Pages

-

Brochure Explosion Safety

40 Pages

-

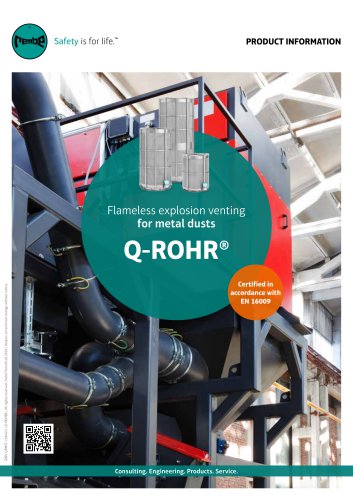

Q-Box Product Information

2 Pages

-

FARADO Product Information

2 Pages

-

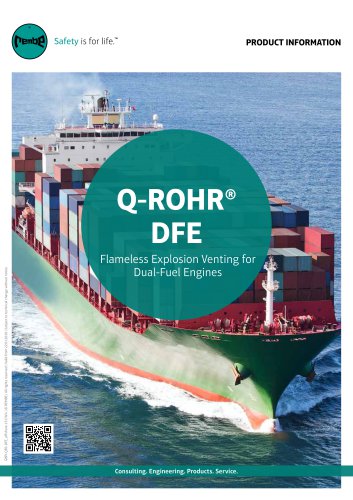

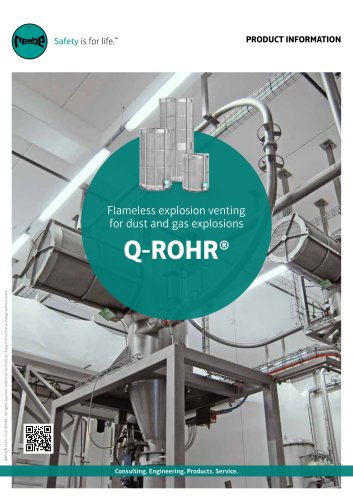

Q-Rohr Product Information

4 Pages

-

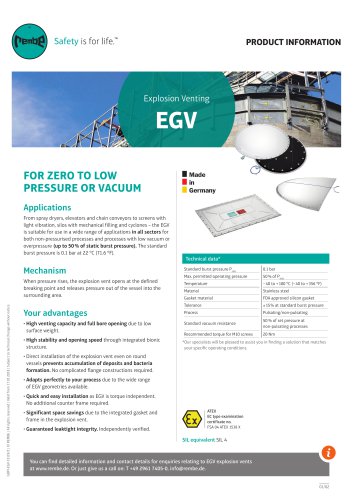

EGV Product Information

2 Pages

-

Rupture Disc Holder IG-HL

2 Pages

-

Rupture Disc Holder IG

3 Pages

-

CBS Product Information

1 Pages

-

SFD Product Information

1 Pages

-

STAR Product Information

1 Pages

-

ODV Product Information

4 Pages

-

IKB Product Information

2 Pages

-

KUB F Product Information

1 Pages

-

KUB V Product Information

1 Pages

-

KUB Product Information

3 Pages

-

EDP Product information

2 Pages

-

ODV+ODU Product Information

2 Pages

-

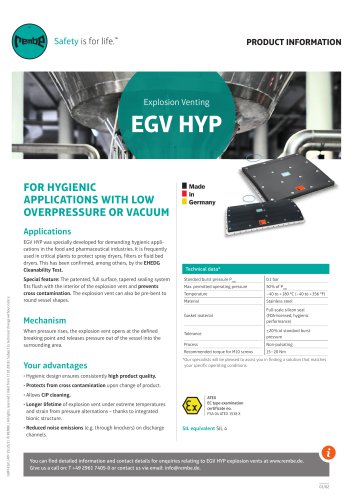

EGV HYP Product information

2 Pages